Simulation test method of residual coal oxidation temperature rising based on actual measurement of air parameters in goaf area

An air parameter and simulation test technology is applied in the field of research on the prevention and control of spontaneous combustion of coal leftovers in goafs of coal mines. Observation and accurate analysis, the effect of less environmental disturbance factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

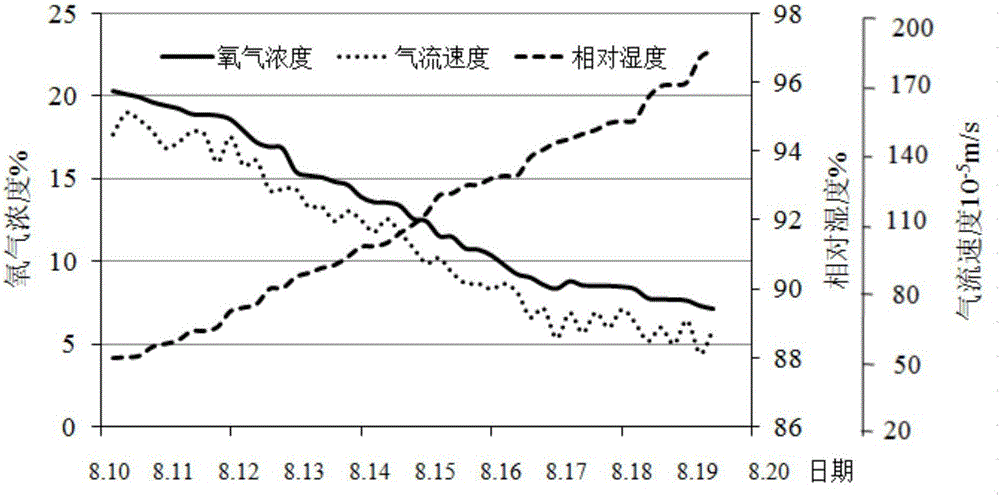

[0031] The present invention provides a simulated test method for residual coal oxidation and temperature rise based on the actual measurement of air parameters in goafs. The following drawings and examples are used to practically apply this technology with the mining of the S1 coal seam 3302 working face of a certain mine as the engineering background. The technical scheme of the present invention is further described in detail.

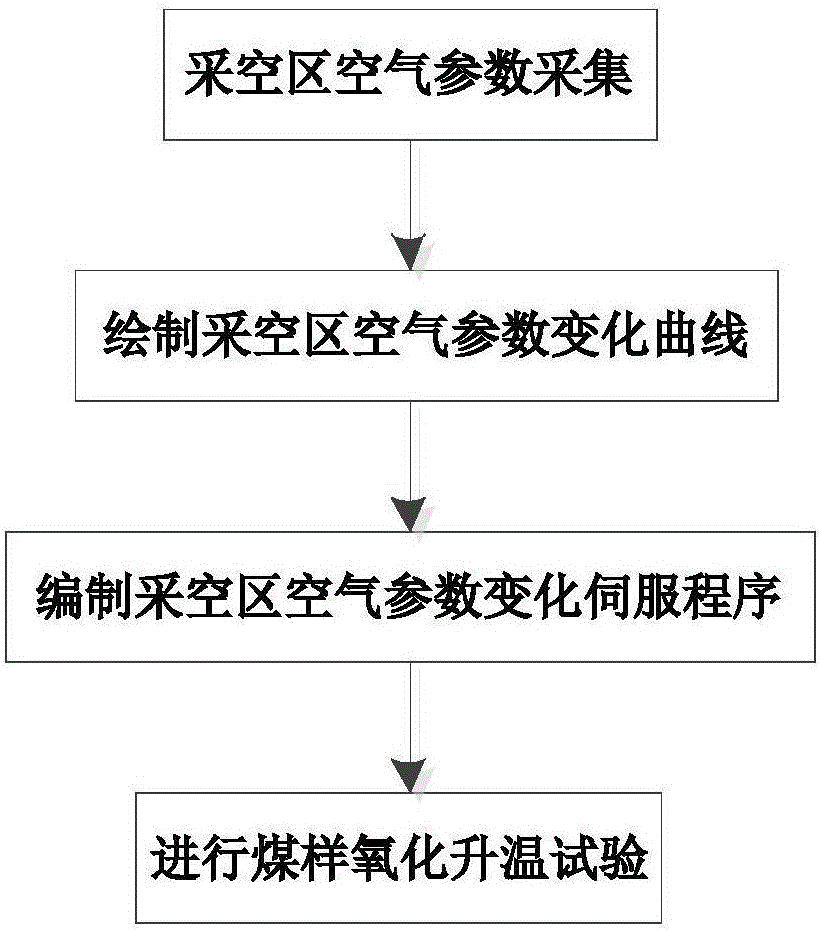

[0032] A simulated test method for oxidation and temperature rise of residual coal based on the actual measurement of air parameters in goafs, characterized in that the main operation steps are as follows:

[0033] Step 1, goaf air parameter collection, which includes the following sub-steps:

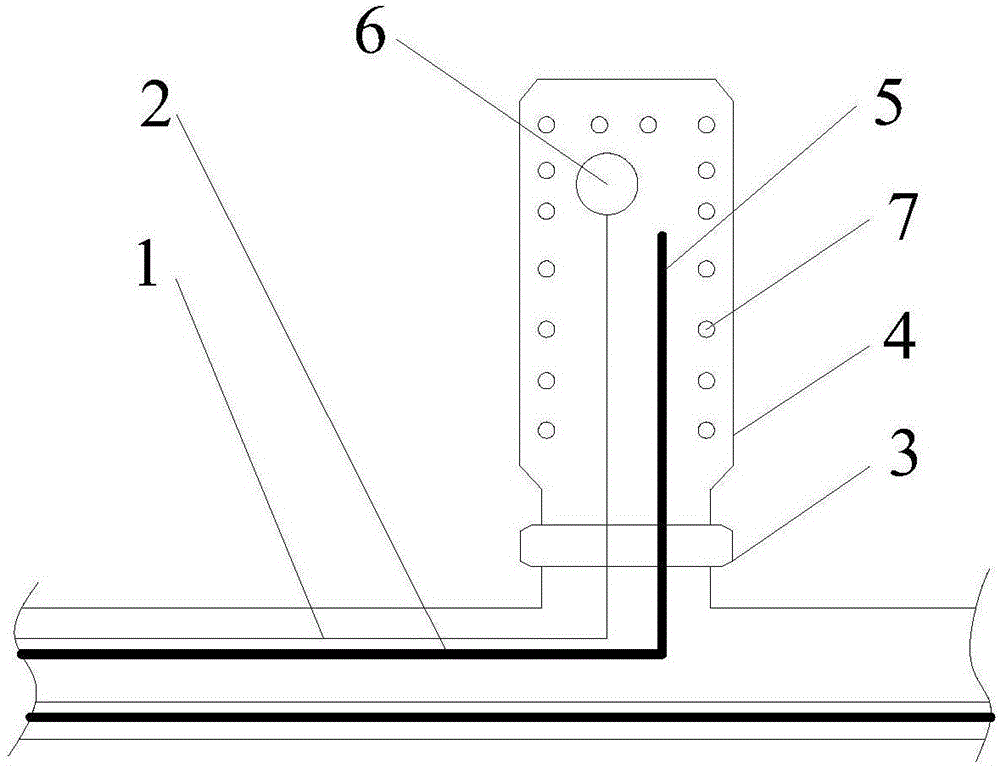

[0034] a The 3302 working face is 160m long, combined with the mining and equipment conditions of the working face, the working face is divided into 9 nodes I 1 , I 2 ,..., I 9 ;

[0035] b Arrange a bundle of tubes along the 3302 working face, and each n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com