A device for testing the diffusion coefficient of an organic coating and a test method based on the device

A technology of organic coating and diffusion coefficient, applied in the direction of measuring devices, diffusion analysis, instruments, etc., can solve the problems of inaccurate testing and large testing errors, and achieve the effect of simple measuring equipment and true and reliable measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

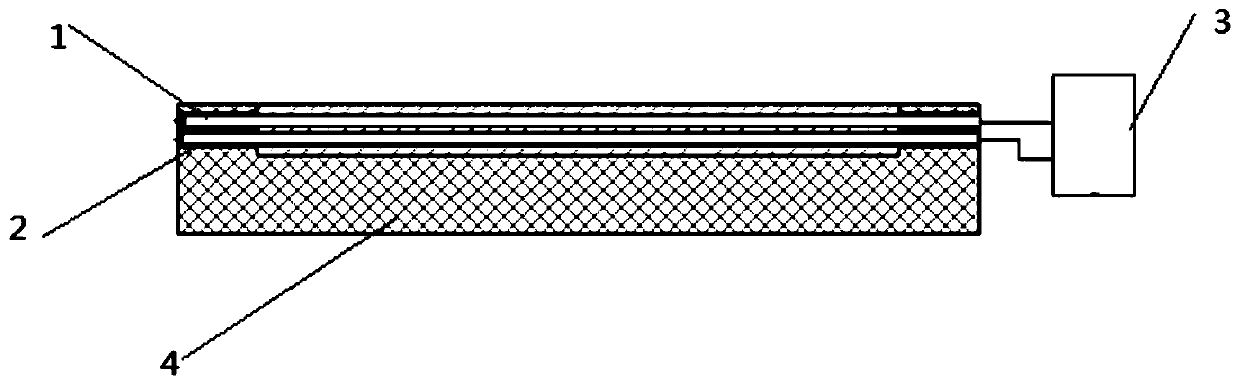

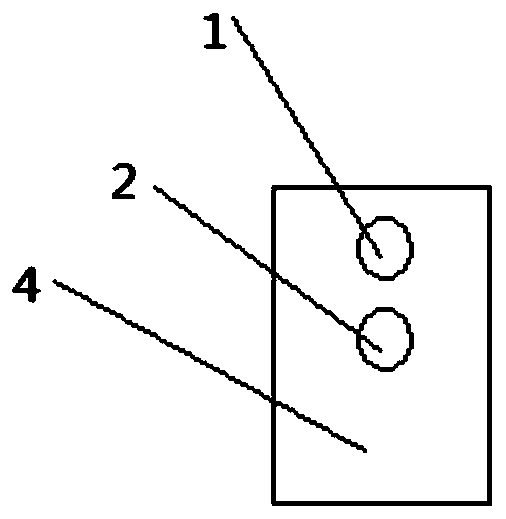

[0067] A kind of organic coating diffusion coefficient testing device of the present invention, such as figure 1 , figure 2 As shown, the polymer box 4 is included, and the material of the polymer box 4 is polyethylene. Electrode A1 and electrode B2 are respectively inserted into the small holes of the electrode. The electrode A1 and electrode B2 are titanium wires with a diameter of 1 mm and a length of 60 mm. The electrodes A1 and electrode B2 are connected to the megger 3 through wires. Wherein, the horizontal directions of the electrode A1 and the electrode B2 are parallel to each other, the distance between the electrode A1 and the electrode B2 is 1.17mm, and the diameter of the small hole is 0.99mm.

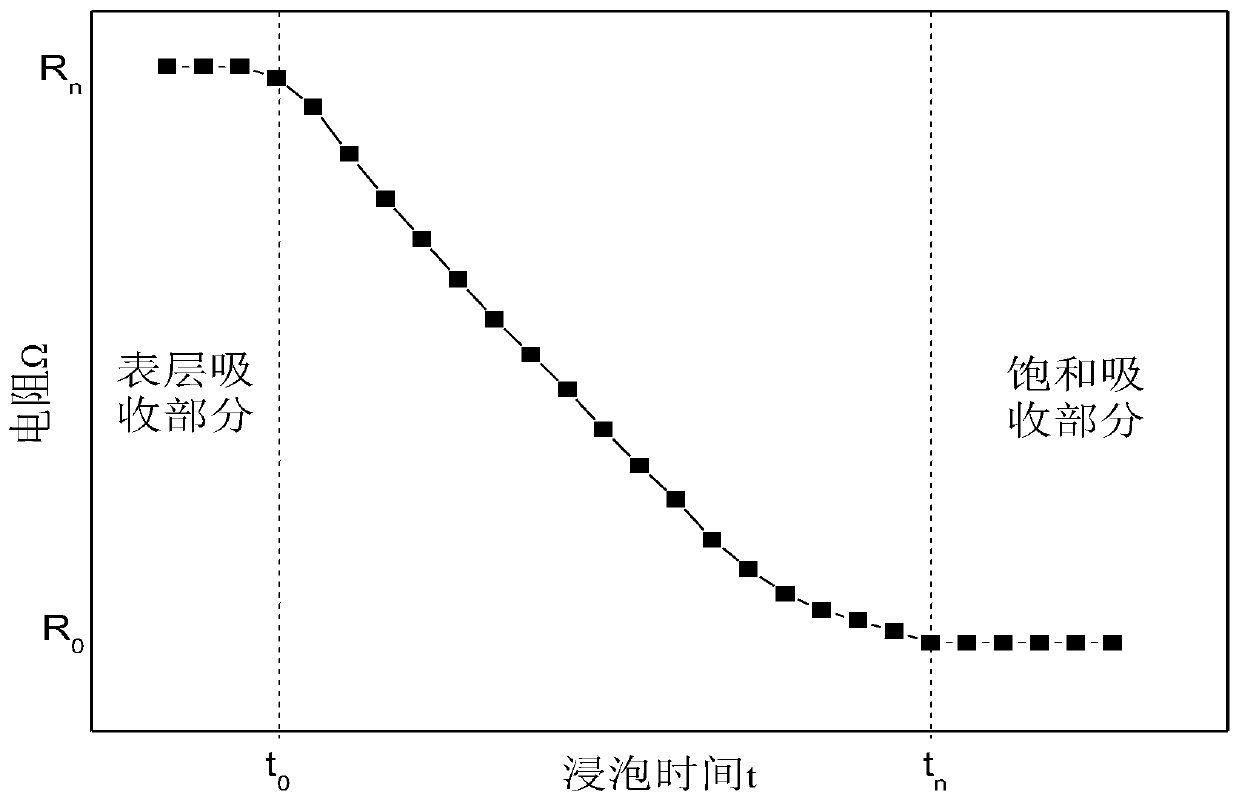

[0068] The test method based on the organic coating diffusion coefficient test device is based on the organic coating diffusion coefficient test device. Electrode A1 and electrode B2 are respectively inserted into the holes, and electrode A1 and electrode B2 are connecte...

Embodiment 2

[0089] A kind of organic coating diffusion coefficient testing device of the present invention, such as figure 1 , figure 2 As shown, the polymer box 4 is included, and the material of the polymer box 4 is polytetrafluoroethylene. The thickness of the box body is 5mm, the length is 50mm, and the width is 25mm. An electrode A1 and an electrode B2 are respectively inserted into two opposite holes. The electrodes A1 and B2 are titanium wires with a diameter of 1 mm and a length of 60 mm. The electrodes A1 and B2 are connected to the megger 3 through wires. Wherein, the horizontal directions of the electrode A1 and the electrode B2 are parallel to each other, the distance between the electrode A1 and the electrode B2 is 1.23 mm, and the diameter of the small hole is 1.01 mm.

[0090] The test method based on the organic coating diffusion coefficient test device is based on the organic coating diffusion coefficient test device. Electrode A1 and electrode B2 are respectively inse...

Embodiment 3

[0111] A kind of organic coating diffusion coefficient testing device of the present invention, such as figure 1 , figure 2 As shown, including the polymer box 4, the material of the polymer box 4 is polyvinyl chloride, the thickness of the box body is 4mm, the length is 50mm, and the width is 25mm. A pair of small holes are symmetrically opened on both sides of the polymer box 4, and each two Electrode A1 and electrode B2 are respectively inserted into the opposite small holes. Electrode A1 and electrode B2 are titanium wires with a diameter of 1 mm and a length of 60 mm. Electrode A1 and electrode B2 are connected to the megger 3 through wires. Wherein, the horizontal directions of the electrode A1 and the electrode B2 are parallel to each other, the distance between the electrode A1 and the electrode B2 is 1.2 mm, and the diameter of the small hole is 1 mm.

[0112] The test method based on the organic coating diffusion coefficient test device is based on the organic coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com