Internal combustion wave rotor gas mixture forming device

An internal combustion wave rotor and wave rotor technology, which is applied in gas turbine devices, jet propulsion devices, machines/engines, etc., can solve the problems of no transition pipe section of the transition pipe device, low economy and practicability, etc., so as to reduce the complexity performance, improve combustion efficiency, and reduce flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

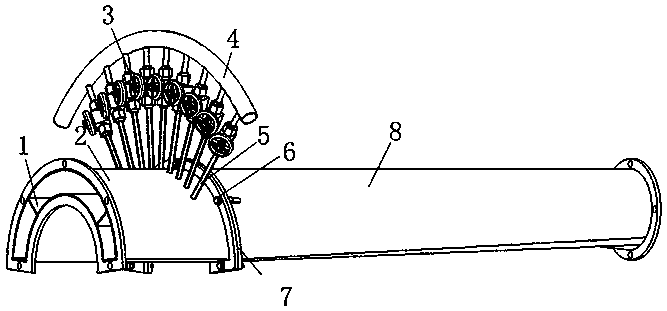

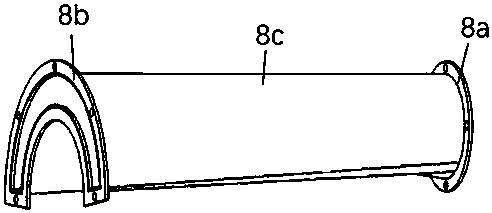

[0023] The structure of the present invention is as figure 1 As shown, it includes the connected transition pipe section 8 and the inlet end section 2 of the wave rotor.

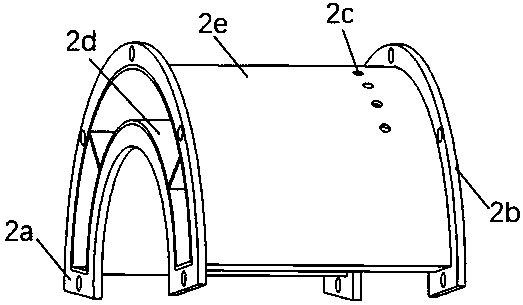

[0024] The structure of the inlet end section 2 of the wave rotor is as follows: figure 2 As shown, it is a cylinder of equal cross section, including an upper wall 2e, a lower wall 2d, a front connecting flange 2a and a rear connecting flange 2b, and its cross section is 170 o Annular cross-section, in which the diameter of the inner ring is 175.2mm, the diameter of the outer ring is 230.8mm, and the circumference angle is 170 o . The inner channel of the wave rotor inlet end section 2 is provided with two deflectors 1, the deflectors 1 divide the wave rotor inlet end section 2 into three inlet areas, and the three inlet areas are filled with different concentrations of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com