An atmospheric pressure tool changing device and method for a super-large-diameter shield machine

A technology of ultra-large diameter and tool changing device, which is applied in earthwork drilling, mining equipment, tunnels, etc. It can solve problems such as economic property, personal safety loss, increased cutter head torque, and difficult construction technology, so as to reduce hidden dangers of safety accidents , avoid operational risks, and highlight the effect of application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

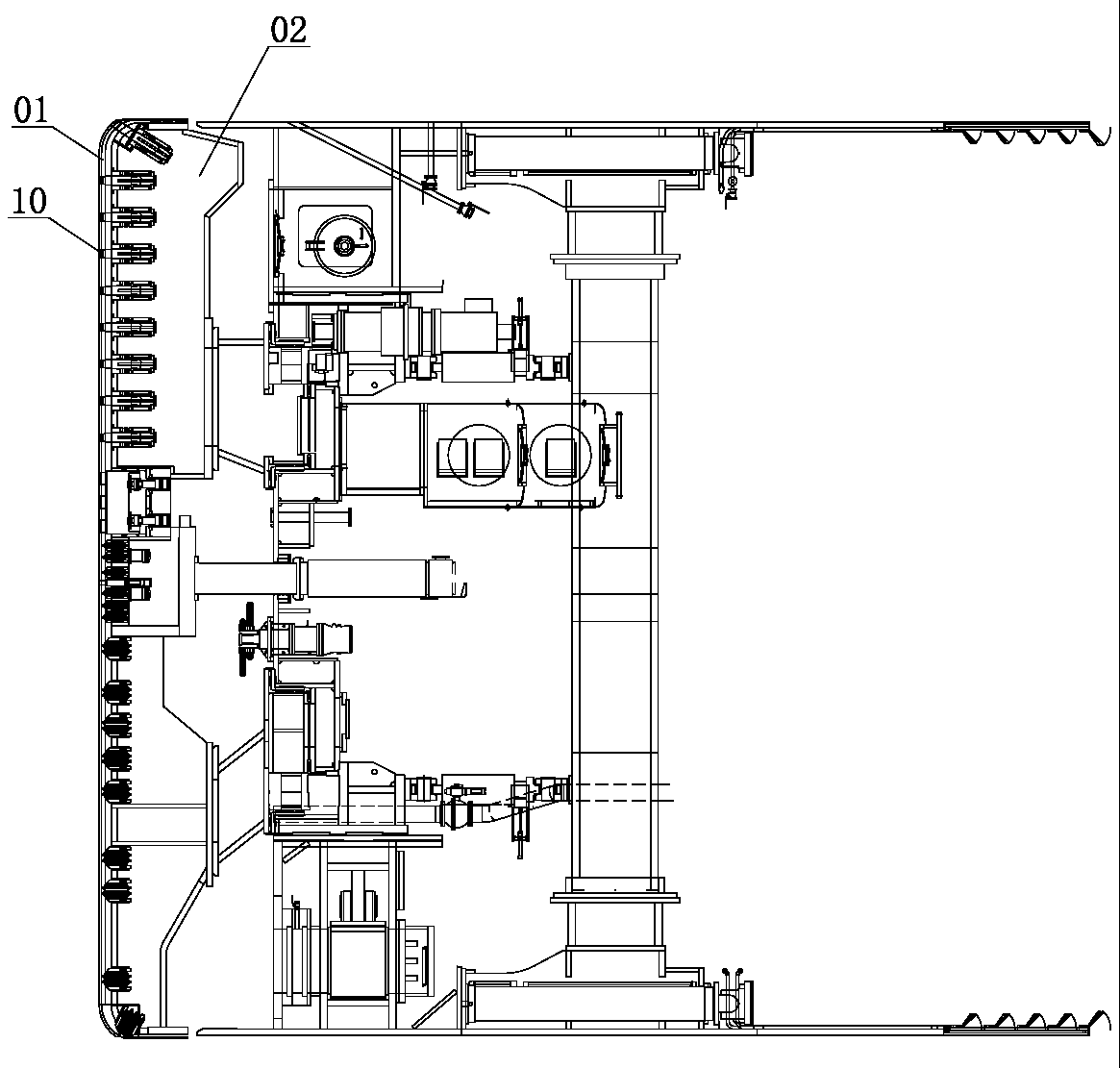

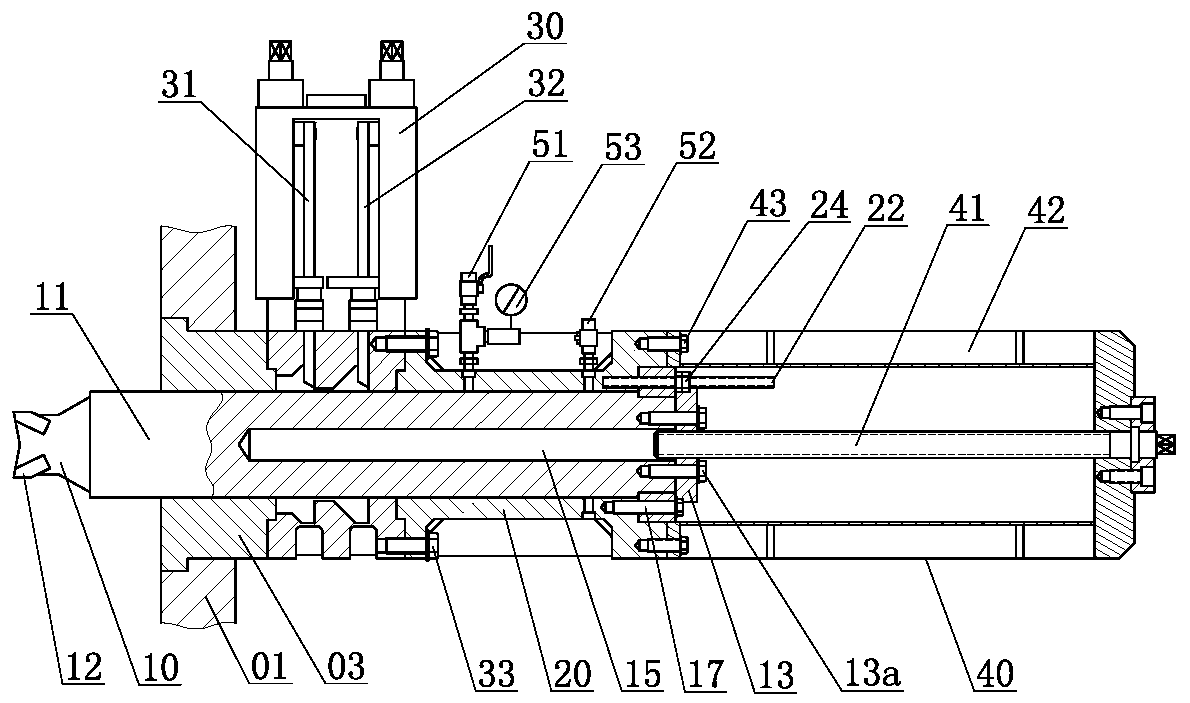

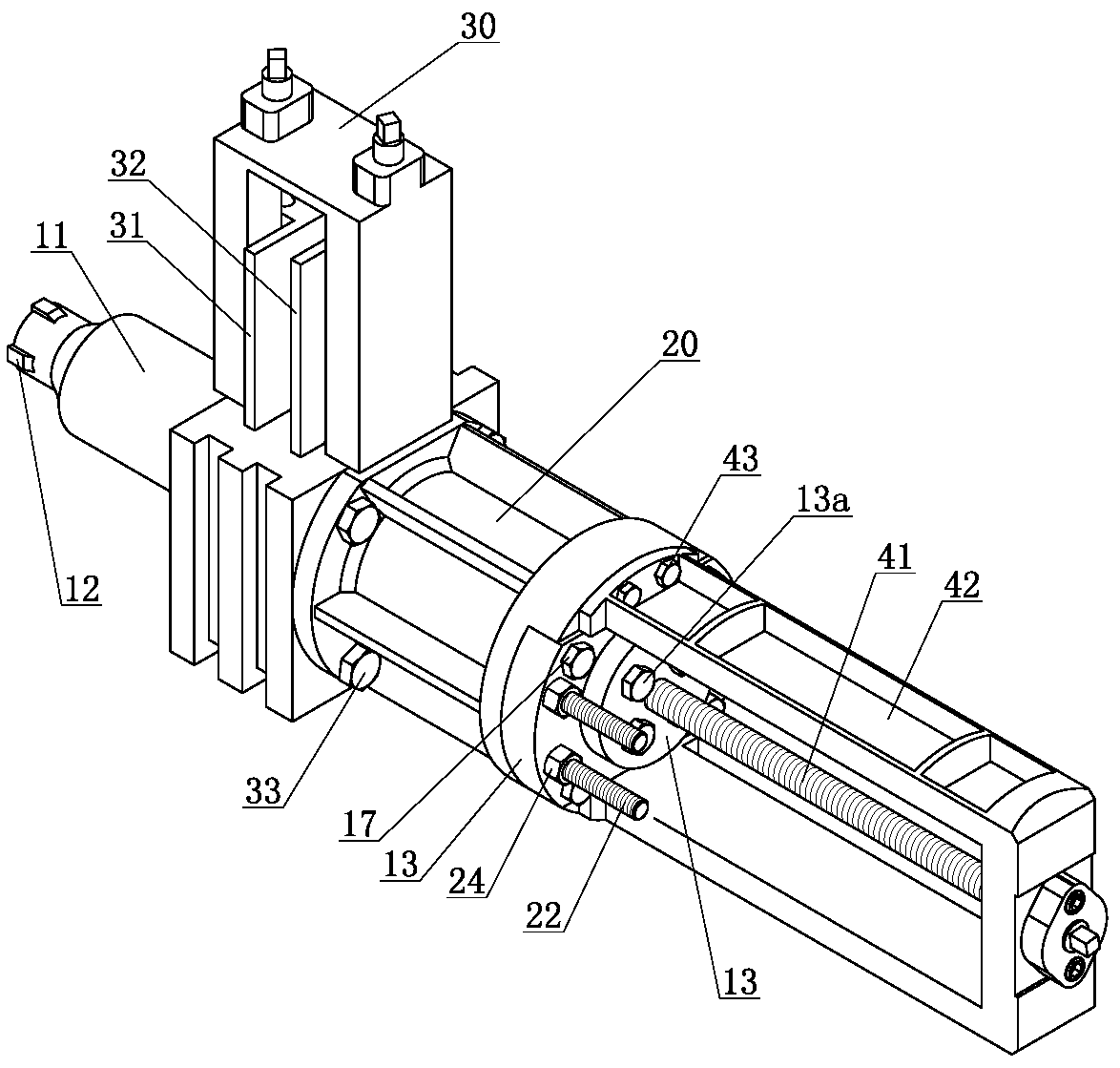

[0063] like Figure 1 to Figure 4 , an atmospheric pressure tool changer for a super-large diameter shield machine, in which a plurality of cutting tools 10 are installed in the spoke working compartment 02 of the shield machine cutter head 01 .

[0064] The spoke working chamber is a working chamber at atmospheric pressure, and a plurality of tool seats 03 are arranged on the cutter head, each tool seat is fixedly installed with a sealing valve 30, each sealing valve is installed with a tool box 20, and each cutting tool Mounted on a knife box, which is fastened to the sealing valve by means of bolts 33.

[0065] The cutting tool is provided with a cutter shaft 11 and a cutter head 12 mounted on the front end of the cutter shaft. The cutter shaft is provided with a central through hole 15 with an open end. The rear end of the cutter shaft is provided with a cutter fixing cover 13, two symmetrical positioning surfaces 18 are arranged on both sides of the cutter fixing cover, ...

Embodiment 2

[0072] A method for changing a tool at atmospheric pressure for a super-large diameter shield machine, this method is a method for changing a cutting tool in the device shown in the first embodiment.

[0073] like figure 1 , Figure 5 , the installation state of the cutting tool on the shield machine cutter head is as follows Figure 5 shown. When the cutting tool is worn or damaged, it needs to be replaced. The normal pressure is maintained in the spoke working chamber 20 of the shield machine cutter head 01, and personnel can enter the working chamber to replace the cutting tools.

[0074] Methods for changing cutting tools include:

[0075] a. Check whether there is water leakage in the tool box. If there is water leakage, inject grease through the grease supply valve 52 to seal the water; then, connect the front end of the fixture frame 42 to the rear end of the tool box 20 through bolts 43 to install the cutting tool The fixture 40 is installed on the tool box; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com