Method for quickly constructing recombinant plasmid

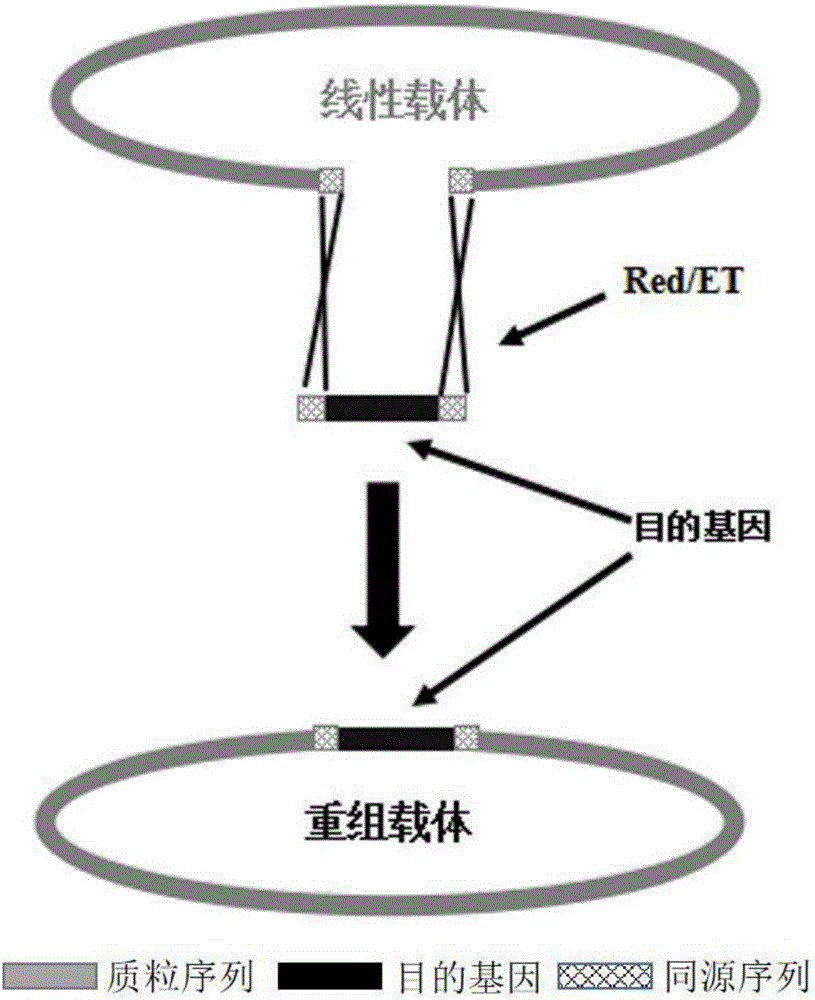

A recombinant plasmid and plasmid technology, applied in the field of genetic engineering, can solve the problems of low recombination efficiency, cumbersome experimental operation, restriction of enzyme cutting sites, etc., and achieve the effects of high positive cloning efficiency, simplified construction steps, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

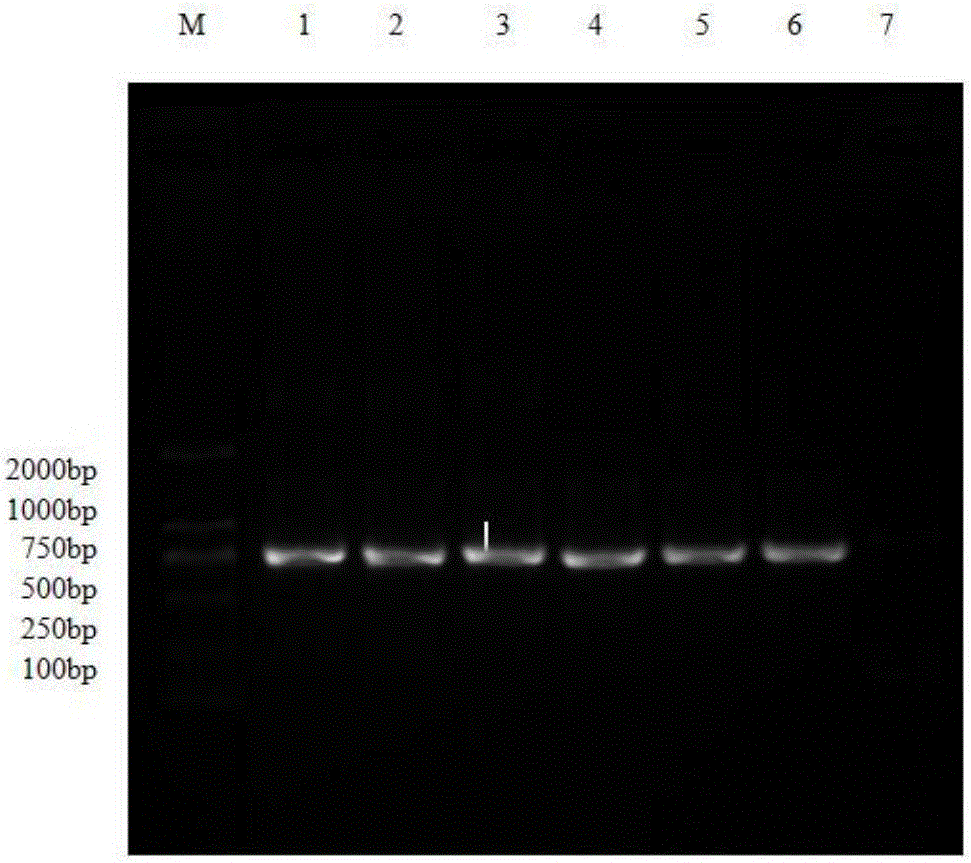

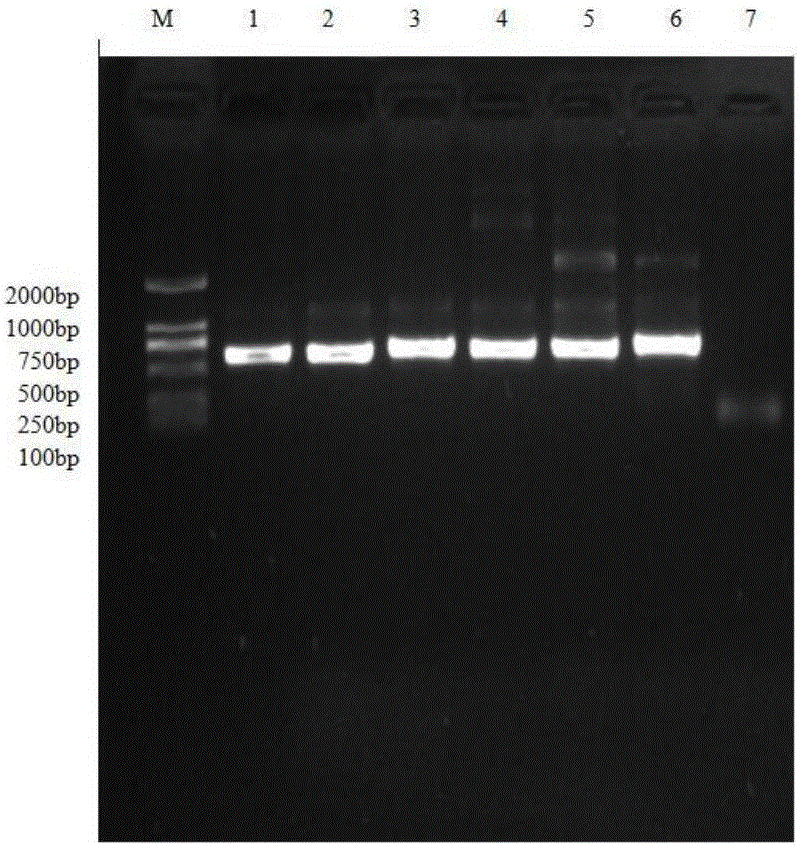

Embodiment 1

[0034] 1. Design of homologous recombination primers

[0035] (1) Take the enhanced green fluorescent protein (EGFP) gene as the design object; pET-41a is the recombinant vector, which is linearized with EcoR I, and the designed upstream primer with a length of 45 bp in the homologous region on one side is:

[0036]

[0037] Downstream primers are:

[0038]

[0039] The upstream primer with a length of 35bp in the homologous region on one side is:

[0040]

[0041] The downstream sequence is:

[0042]

[0043] The underlined part in italics is the sequence at both ends of the EcoR I site (including the EcoR I restriction site sequence) on the pET-41a vector (used for homologous recombination with the linear pET-41a), and the rest is the sequence of the amplified EGFP gene .

[0044] 2. Preparation of BJ5183 Competent Bacteria Carrying pKD46 Plasmid

[0045] (1) Pick a single colony of the BJ5183 strain carrying the pKD46 plasmid obtained by a common transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com