Anion-cation compound antibacterial laundry detergent

An anion-cation and laundry detergent technology, applied in the direction of cationic surface-active compounds, anion-cation-nonionic surface-active compounds, detergent compositions, etc., can solve problems such as system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

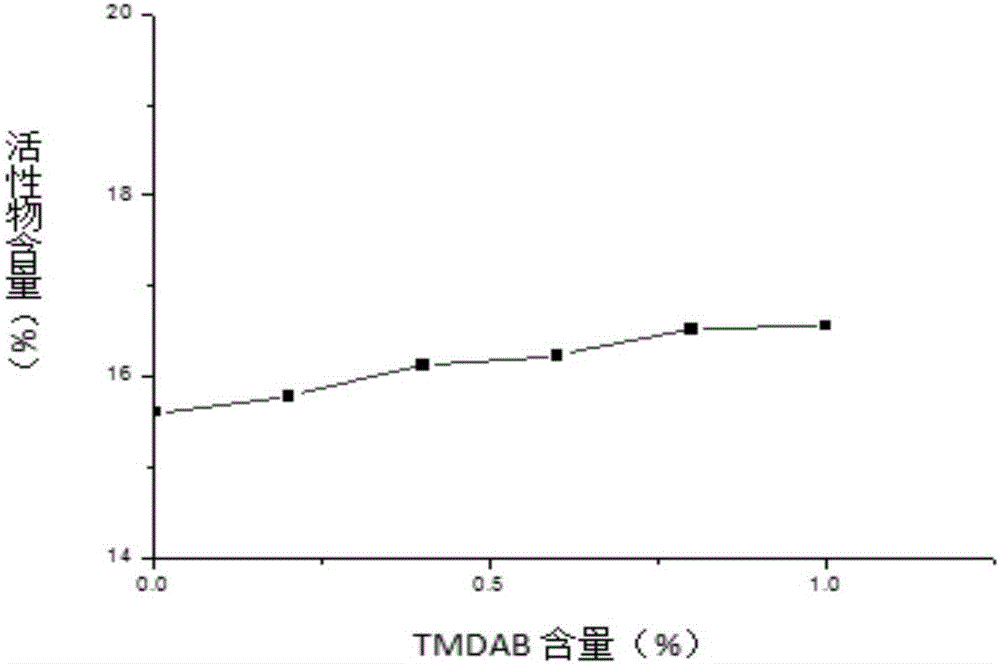

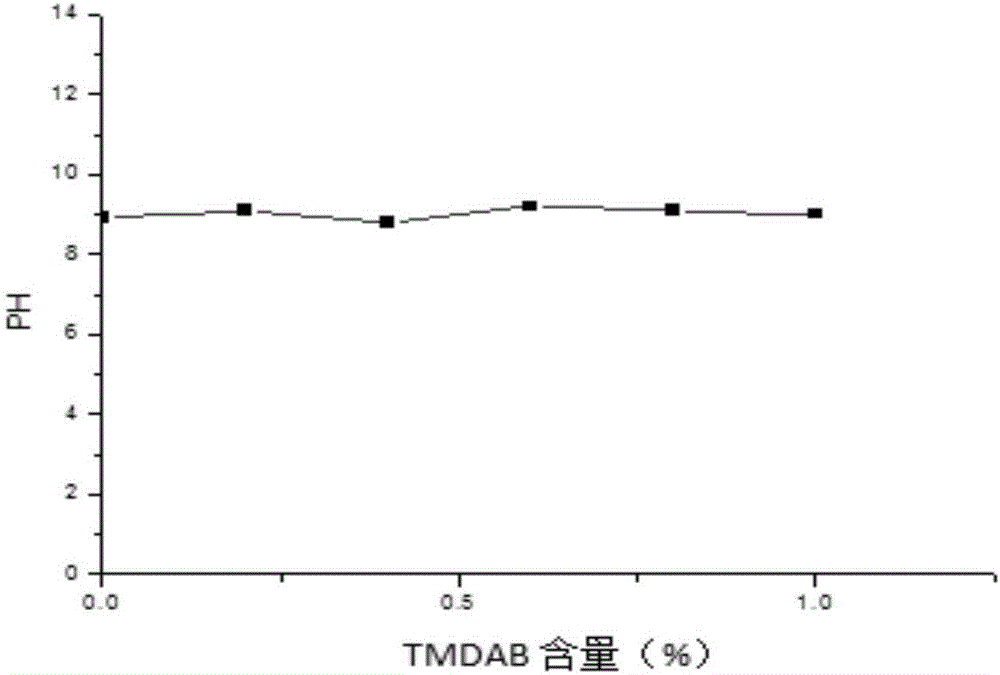

[0026] The formula of table 1 six laundry detergents

[0027]

[0028]

[0029] The steps of making laundry detergent are as follows:

[0030] Add the deionized water at 70°C into the chemical material tank, and then mix the sodium dodecylbenzenesulfonate, fatty alcohol polyether sodium sulfate, fatty alcohol polyoxyethylene ether, and coconut oil according to the formula ratio Amidopropyl amine oxide is added to it, and stirred evenly to obtain solution 1; when the temperature of solution 1 drops to 40-45°C, add the tetradecylmethyldihydroxyethylammonium bromide and sodium chloride according to the proportion ; When the temperature drops to 35°C, add sodium citrate, sodium hydroxide and essence according to the ratio. In this process, attention should be paid to accurate weighing and replenishment of evaporated water.

[0031] Take the preparation of formula 2 laundry detergent as an example: add 74.69kg of deionized water (at a temperature of 70°C) into the chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com