Sand-in-water environment-friendly paint achieving wet-on-wet construction with high build paint and preparation method of sand-in-water environment-friendly paint

An environmentally friendly coating, wet-on-wet technology, applied in the direction of coating, etc., can solve the problems of poor product stability, poor imitation fire stone effect, easy to break the color point, etc., to achieve excellent weather resistance and stability, low emission and environmental protection Requirements, the effect of meeting the requirements of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The embodiment of the present invention provides a preparation method of the above-mentioned sand-in-water environmental protection coating applied wet-on-wet with the high-build type coating, including:

[0048] Make sandy grains:

[0049]According to the size and proportion of the flamed stone pattern, add the adjusted base paints of each color into the protective glue in proportion, so that the base paints of each color are completely soaked in the protective glue, and then use a pre-selected mesh The sieve is used for granulation to obtain sand-containing particles of each color; the color matching of the base paint is as follows: the colorist can color the base paint according to the pattern of the fired stone, in order to ensure the stability of the color particles , try to choose inorganic color paste with less additives, and try to control the amount of color paste added. Generally, the amount of color paste added should not exceed 5% of the quality of the base ...

Embodiment 1

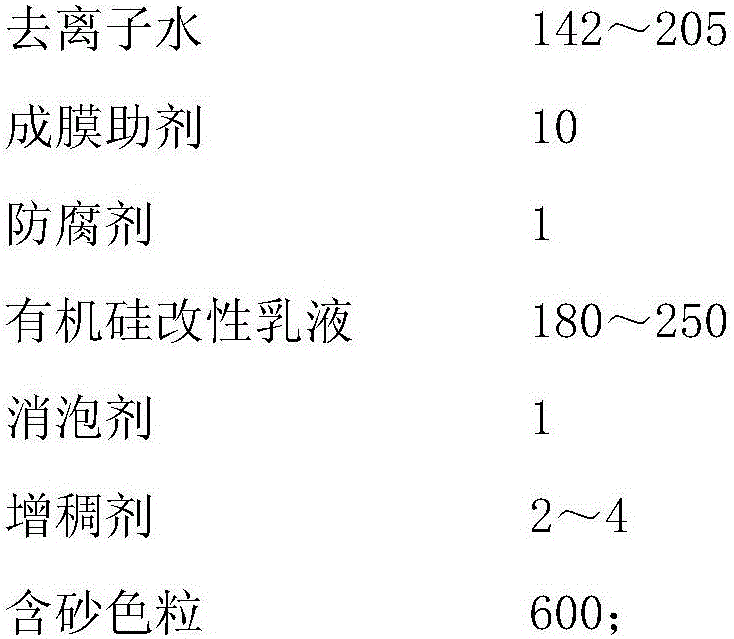

[0072] This embodiment provides a kind of sand-in-water environmental protection coating with wet-on-wet application of high-build coatings. It is made of sand-containing color particles prepared from base paint and protective glue and other components. The preparation method is: first prepare the base paint respectively Paint and protective glue, made of base paint and protective glue with sand-containing color particles, and finally use the prepared sand-containing color particles to prepare the finished paint, specifically including (the unit of the raw materials involved in the following is: kg):

[0073] A: Prepare base paint:

[0074]

[0075] Add deionized water, cellulose, dispersant, defoamer, fungicide, pH adjuster, antifreeze and film-forming aid in the base paint formula to the mixer, mix and disperse evenly at a low speed of 200-300 for 5 minutes, then add Rutile titanium dioxide is dispersed at a high speed of 1000-12000 rpm for 10 minutes, then adjusted to a ...

Embodiment 2

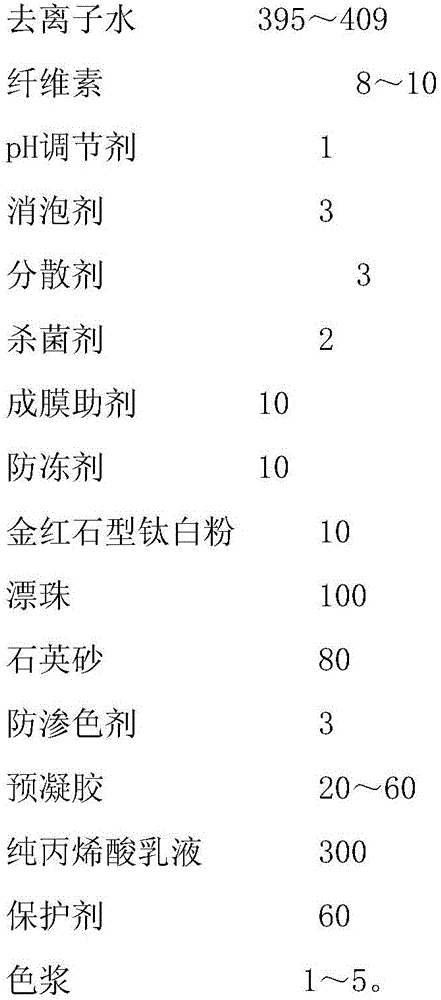

[0086] This embodiment provides a kind of sand-in-water environmental protection coating with wet-on-wet application of high-build coatings. It is made of sand-containing color particles prepared from base paint and protective glue and other components. The preparation method is: first prepare the base paint respectively Paint and protective glue, made of base paint and protective glue with sand-containing color particles, and finally use the prepared sand-containing color particles to prepare the finished paint, specifically including (the unit of the raw materials involved in the following is: kg):

[0087] A: Prepare base paint:

[0088]

[0089] The specific preparation process of the above-mentioned base paint is the same as that of Example 1.

[0090] B: Preparation of protective glue:

[0091] Deionized water 928 Protective powder 70 Hydroxyethyl cellulose 2

[0092] The specific preparation process of the above-mentioned protective glue i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com