A kind of spray paint and preparation method thereof

A paint and propellant technology, applied in coatings, anti-corrosion coatings, cellulose coatings, etc., can solve non-polar plastic substrate adhesion and color diversification, non-polar non-scratch resistance Adhesion to plastic substrates, undisclosed scratch resistance and weather resistance, etc., to achieve strong electroplating effect, good scratch resistance, and improve the weather resistance and decorative effects of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

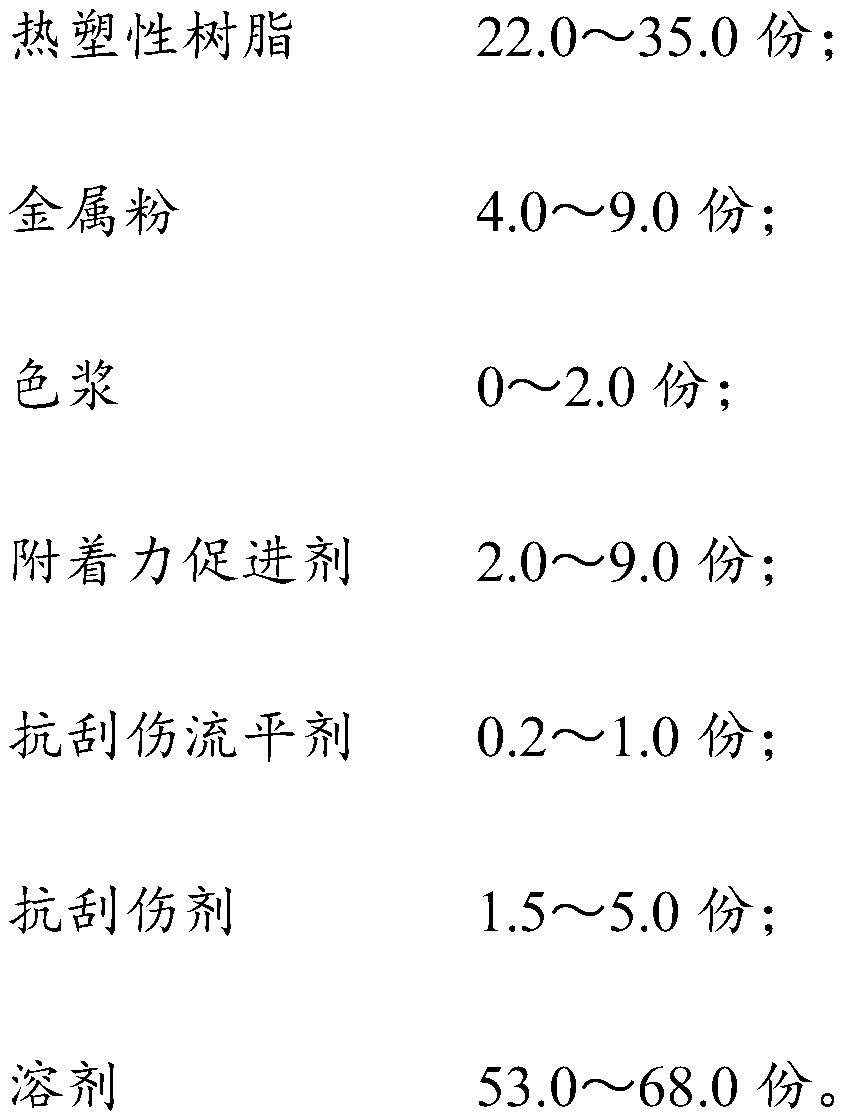

Method used

Image

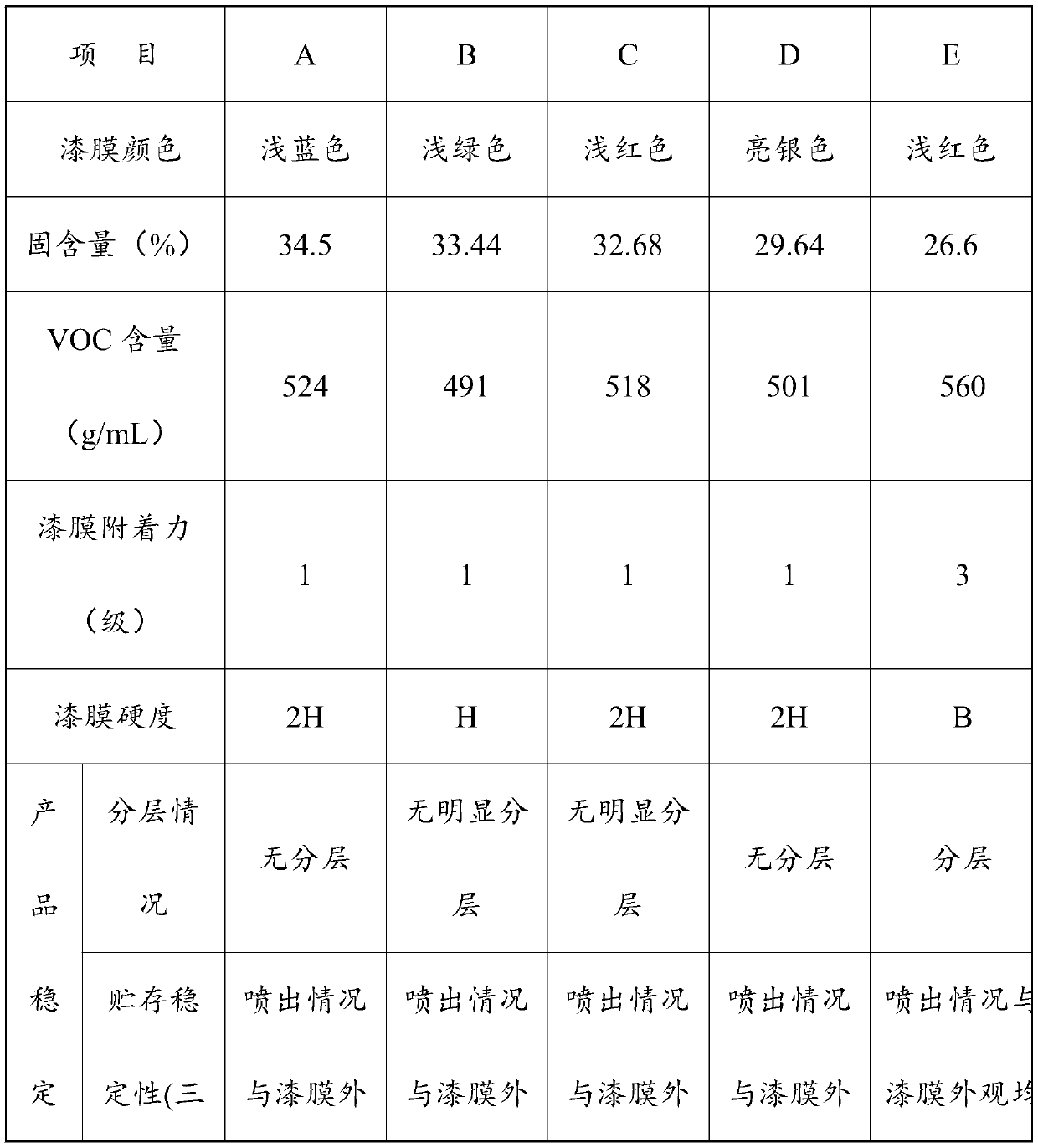

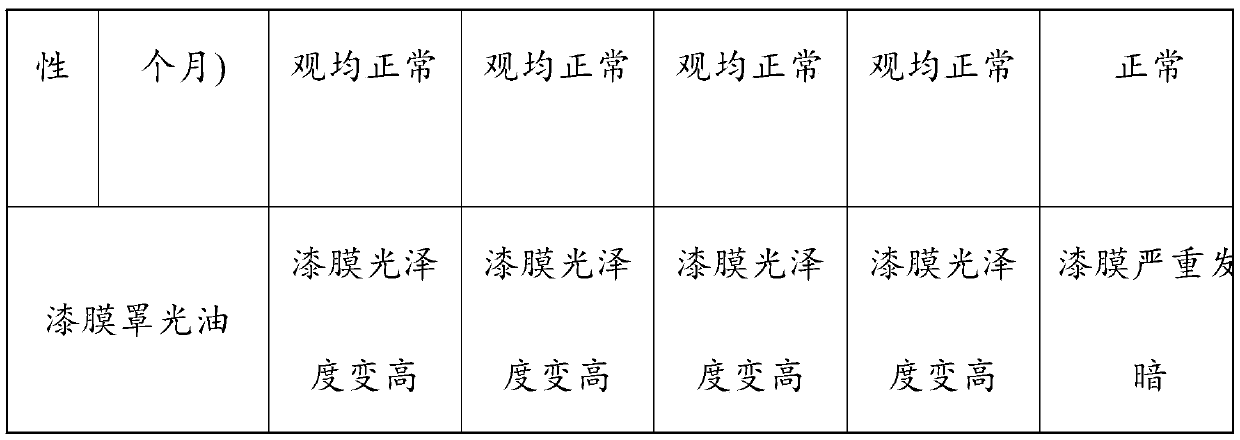

Examples

Embodiment 1

[0040] S1. Add 4 parts of cyclohexane and 6 parts of sec-butyl acetate, start stirring, slowly add 5 parts of cellulose resin and 17 parts of acrylate modified petroleum resin, disperse at 1200r / min for 1.5h until completely dissolved;

[0041] S2, add 4 parts of cyclohexane, 6 parts of sec-butyl acetate, start stirring, add 2 parts of modified polyamide wax and stir well, add 6 parts of electroplating silver paste (average particle size is 10 microns), 0.8 parts of zinc powder in turn , continue to disperse for 0.5h after stirring;

[0042] S3. Add the remaining 12 parts of cyclohexane, 16 parts of sec-butyl acetate, 7 parts of butanone, 1 part of dimethyl carbonate, 1.4 parts of propylene glycol methyl ether, 0 parts of polyethylene modified acrylic resin, and 0.5 parts of phthalocyanine blue Slurry, turn on the machine and stir well, add S1 and S2 in turn in the dispersed state, add 1 part of cellulose resin, 0.5 part of nano-alumina after stirring, disperse at 800r / min for...

Embodiment 2

[0045] S1. Add 5 parts of cyclohexane and 5 parts of sec-butyl acetate, start stirring, slowly add 2 parts of cellulose resin and 18 parts of acrylate modified petroleum resin, disperse at 1200r / min for 1.5h until completely dissolved;

[0046] S2, add 5 parts of cyclohexane, 5 parts of sec-butyl acetate, start stirring, add 1.0 parts of modified polyamide wax and stir well, then add 4.5 parts of electroplating silver paste (average particle size is 6 microns), 0.5 parts of zinc powder , continue to disperse for 0.5h after stirring;

[0047]S3, add the remaining 15 parts of cyclohexane, 15 parts of sec-butyl acetate, 6 parts of butanone, 1 part of dimethyl carbonate, 2 parts of propylene glycol methyl ether, 6 parts of polyethylene modified acrylic resin, 0.8 part of phthalocyanine green pulp , turn on the machine and stir evenly, add S1 and S2 in turn in the dispersed state, add 1 part of cellulose resin, 1 part of nano-alumina after stirring, disperse at 800r / min for 10min, ...

Embodiment 3

[0050] S1. Add 6 parts of cyclohexane and 4 parts of sec-butyl acetate, start stirring, slowly add 3 parts of cellulose resin and 8 parts of acrylate modified petroleum resin, disperse at 1000r / min for 1 hour until completely dissolved;

[0051] S2, add 6 parts of cyclohexane, 4 parts of sec-butyl acetate, start stirring, add 1.5 parts of modified polyamide wax and stir well, add 5 parts of electroplating silver paste (average particle size is 8 microns), 0.5 parts of zinc powder in turn , and continue to disperse for 1 hour after stirring;

[0052] S3, add the remaining 15 parts of cyclohexane, 10 parts of sec-butyl acetate, 8 parts of butanone, 1.9 parts of propylene glycol methyl ether, 18 parts of chlorinated polypropylene modified acrylic resin, 1.6 parts of iron oxide red paste, start the machine and stir well, Add S1 and S2 sequentially in the dispersed state, stir well, add 1 part of cellulose resin, 2 parts of nano-alumina, disperse at 700r / min for 20 minutes, add 4.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com