A cement kiln alternative fuel gasification staged combustion method and device

A technology of gasification classification and combustion method, which is applied in the field of cement kiln alternative fuel gasification classification combustion and equipment, which can solve the problems of increased ammonia escape risk, insignificant efficiency improvement, and sharp increase in ammonia water consumption, so as to reduce pollution emissions, The temperature distribution of the calciner is uniform and the effect of reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

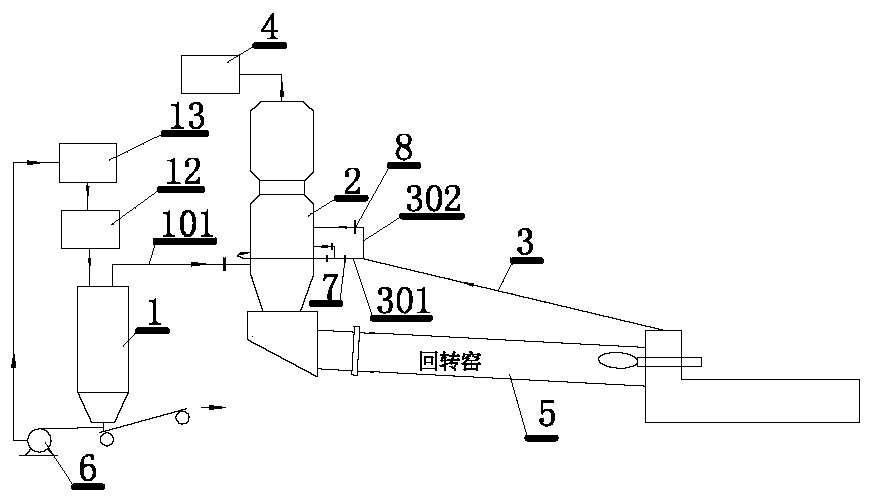

[0028] A cement kiln alternative fuel gasification staged combustion method, such as figure 1 As shown, the method includes generating a large amount of gasification gas rich in reducing base substances after the pyrolysis gasification of the alternative fuel output from the pyrolysis gasifier 1, the gasification gas is sent out through the pyrolysis gas pipeline 101, and sent into cement The tertiary air of the cement kiln in the kiln calciner 2, the tertiary air of the cement kiln system is the high-temperature air after heat exchange with the clinker from the cold air sent by the blower to the grate cooler; the high-temperature air passes through the rotary kiln and the grate cooler The connecting shaft of the machine enters the kiln hood of the rotary kiln. Part of it enters the rotary kiln as the combustion-supporting air of the kiln head, and the rest is the tertiary air. The tertiary air is sent into the calciner at the end of the kiln through the air duct 3 as combust...

Embodiment 2

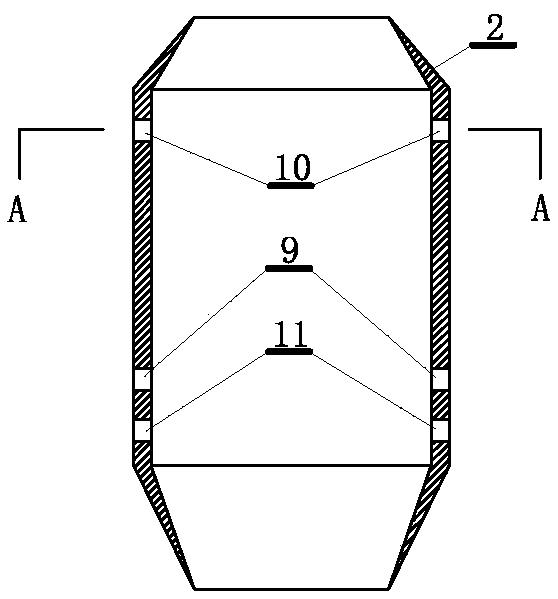

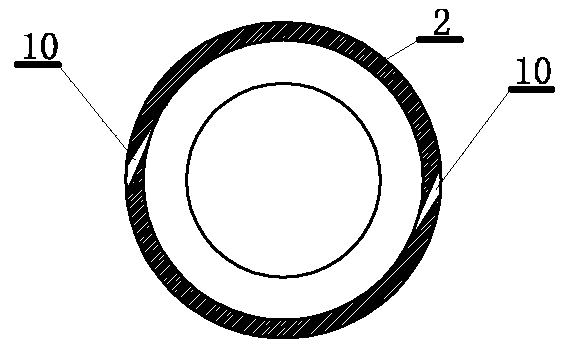

[0035] A cement kiln substitute fuel gasification staged combustion device for realizing the method described in embodiment 1, such as figure 1 As shown, the device includes a decomposition furnace 2 arranged at the end of the cement kiln rotary kiln 5 and an independently arranged pyrolysis gasifier 1, the pyrolysis gasifier is provided with a gasification blower 6, and the gasification of the pyrolysis gasifier The flow rate is controlled by a fan frequency converter, the gasification gas of the pyrolysis gasifier is connected to the calciner through the pyrolysis gas pipeline 101, and the tertiary air pipeline 3 of the cement kiln is connected to the calciner, wherein the tertiary air pipeline is divided into two The first air duct 301 and the second air duct 302 are respectively, the first air duct is connected to the tertiary air input port at the bottom end side of the calciner, and the second air duct is connected to the third air duct at the upper end side of the calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com