Preparation method for vertically arrayed bimetallic hydrotalcite nanosheet

A technology of vertical arrangement and nanosheets, which is applied in the field of nanomaterials, can solve the problems of uneven synthetic morphology of hydrotalcite, inability to expose active sites, low reactivity, etc., and achieve strong application, easy mass production, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

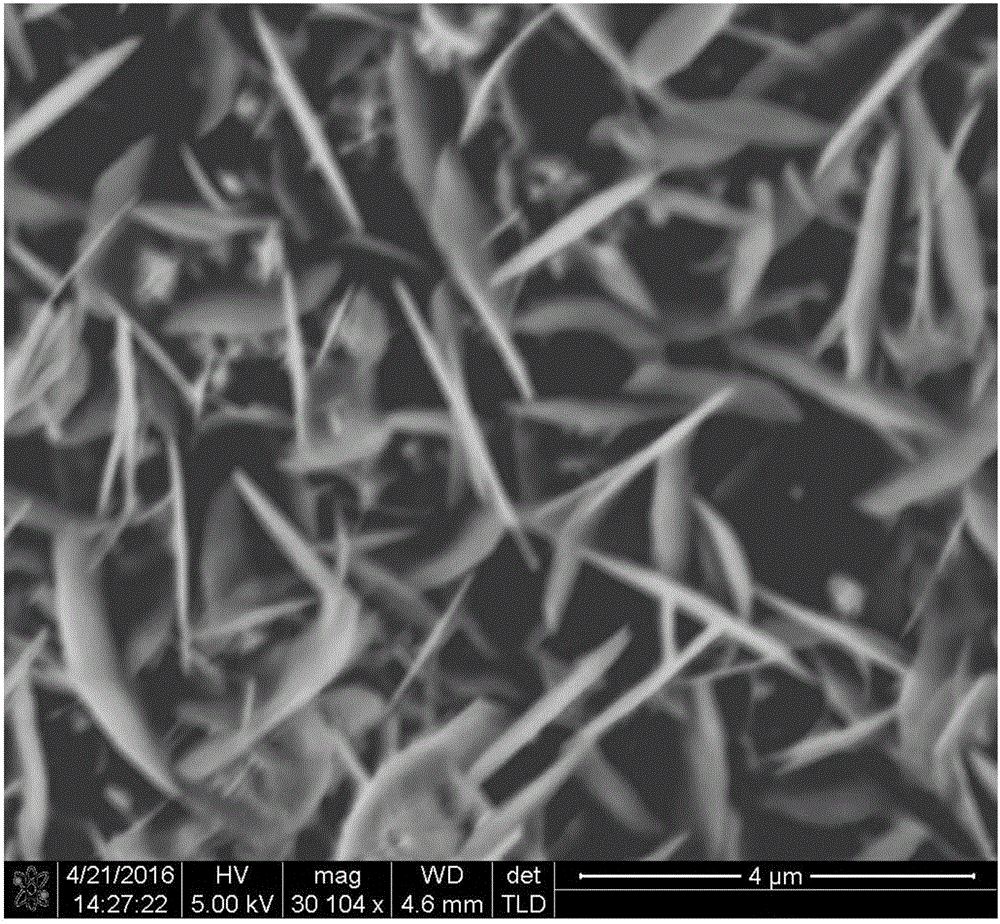

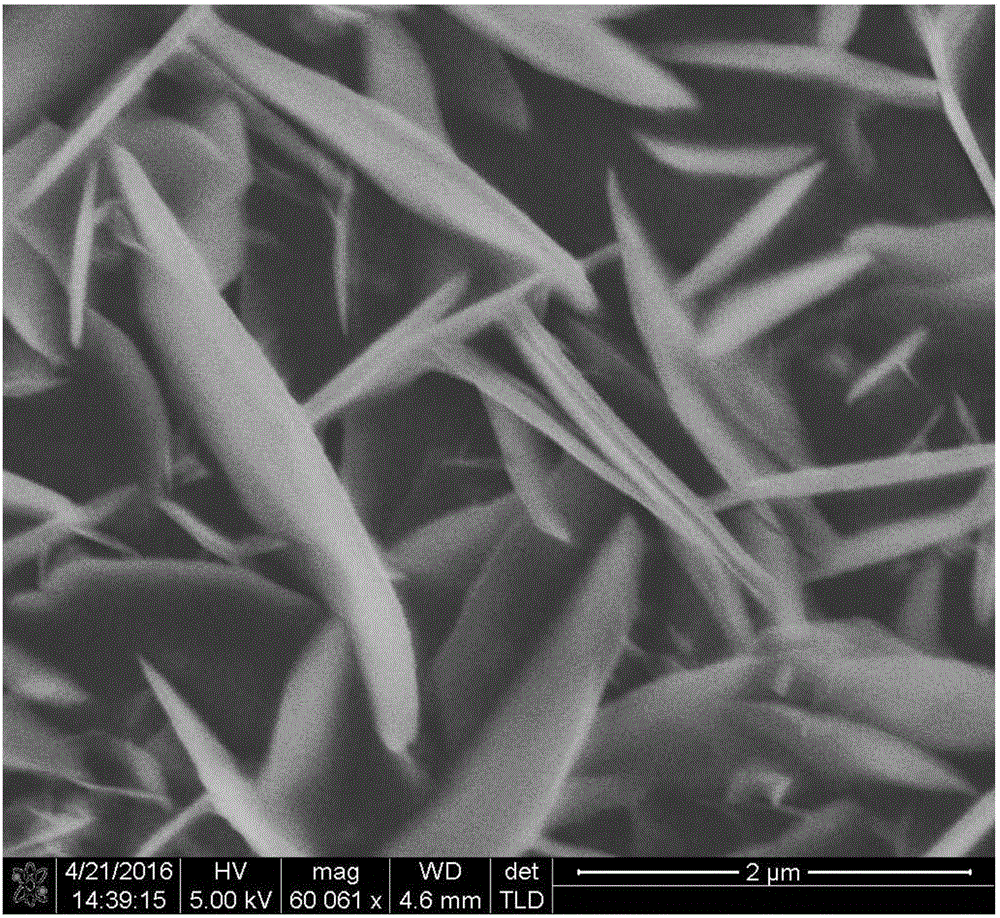

[0020] The present invention proposes a simple method for preparing vertically arranged bimetallic hydrotalcite nanosheets in large quantities, using three-dimensional graphene foam, porous carbon foam, or porous metal foam as a conductive matrix, and changing the metal salt precursor and its concentration. Crystallization of bimetallic hydrotalcites by hydrothermal reaction at different temperatures.

[0021] The specific preparation operation steps take the preparation of iron-nickel hydrotalcite nanosheets as an example:

[0022] (1) nickel nitrate, ferric nitrate, urea are dissolved in appropriate amount of water, and it is transferred in the hydrothermal reaction kettle;

[0023] (2) Immerse the conductive substrate (three-dimensional graphene foam, porous carbon foam, or porous metal foam) in the reaction solution of the hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com