Method for preparing graphene-like material from furfural resin, graphene-like material and use thereof

A furfural resin, graphene technology, applied in the preparation/purification of graphene, graphite, carbon, etc., can solve the problems of incompatibility, difficulty in mass production, graphene hinders graphene from realizing potential value, etc., and achieves high thermal stability. , excellent performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] This embodiment relates to a graphene-like material and its preparation method and application.

[0024] The method for preparing graphene-like material by furfural resin comprises the following steps:

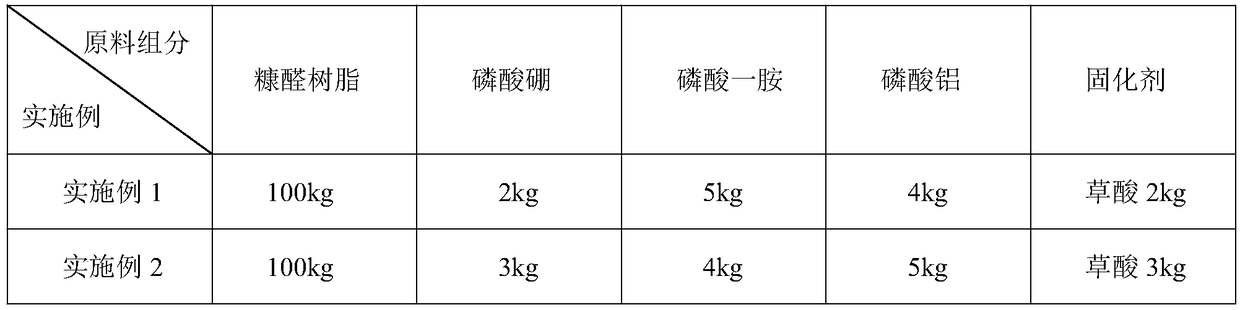

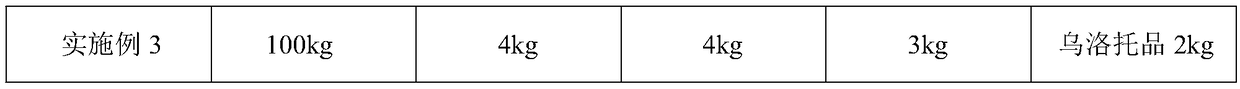

[0025] a. Add furfural resin to the reaction kettle, add boron phosphate, monoamine phosphate, aluminum phosphate and curing agent, preheat to 26-38°C with a solar water heater and stir for 10-12 minutes to obtain a well-mixed furfural mixture;

[0026] b. Put the furfural mixture into the mold and push it into the greenhouse, raise the temperature to 60-100°C, keep it warm for 8 hours, then raise the temperature to 100-130°C, keep it warm for 6 hours, and then solidify;

[0027] c. Put the fully solidified furfural mixture into a vacuum carbonization furnace for vacuum carbonization: vacuumize, under a vacuum degree of -0.1MPa, slowly raise the temperature, and raise the temperature from room temperature to 200°C at a rate of 1-2°C in 4 minutes. Keep warm for 8-10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com