Fully-automatic ice crystal coolant filling equipment

A filling equipment and coolant technology, applied in the field of fully automatic ice crystal coolant filling equipment, can solve the problems of reduced service life, damage to the flowmeter instrument in the system, and large fluid changes in the feeding pipe body, etc., to achieve a reasonable structural design , high-efficiency filling volume, and strong production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

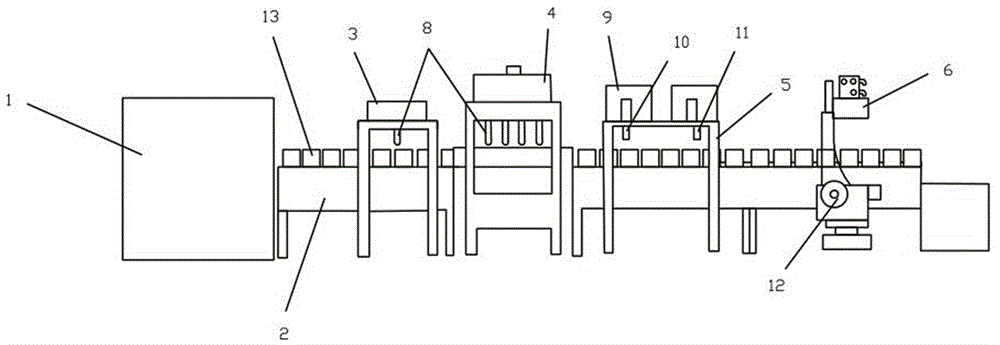

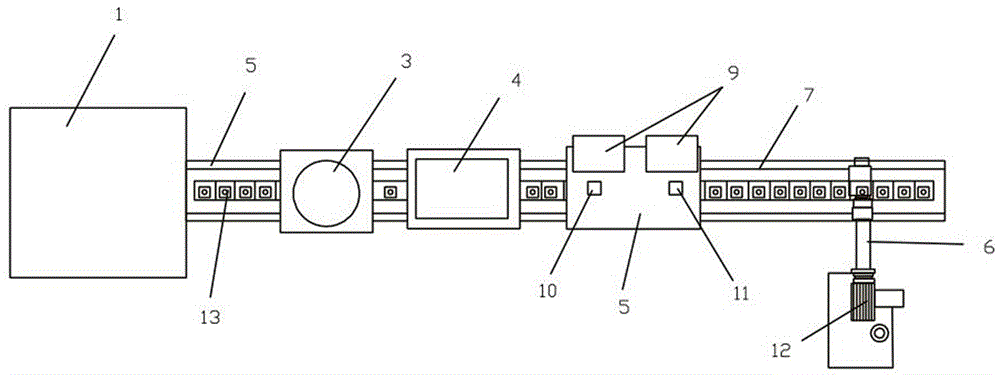

[0014] A kind of full-automatic ice crystal coolant filling equipment described in this embodiment 1, such as figure 1 with figure 2 As shown, it includes an injection molding machine 1 that injects bottles 13, a conveying mechanism 2 that conveys the bottles that come out of the injection molding machine, and also includes a crystal powder filling mechanism 3 that is arranged on the conveying mechanism to sequentially fill the crystal powder, and carries out water filling. Filling water filling mechanism 4. Rubber plug screw capping mechanism for pressing the bottle 5. Six-axis robot with six degrees of freedom for grabbing the filled bottle to the packaging area or loading area 6; The mechanism is also provided with a limit mechanism 7 that limits the position of the bottle before entering each process. The product comes out of the injection molding machine to the conveying mechanism, and is conveyed to the crystal powder filling mechanism. After the crystal powder tank me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com