Pipetting device capable of self-checking air tightness and accurately extracting and pipetting method thereof

A pipetting device and air-tightness technology, which is applied in the direction of fluid tightness testing, measuring devices, chemical instruments and methods, etc., and can solve problems such as poor sealing, inability to accurately detect, and inability to accurately measure the volume of extracted sample fluid, etc. problem, to achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

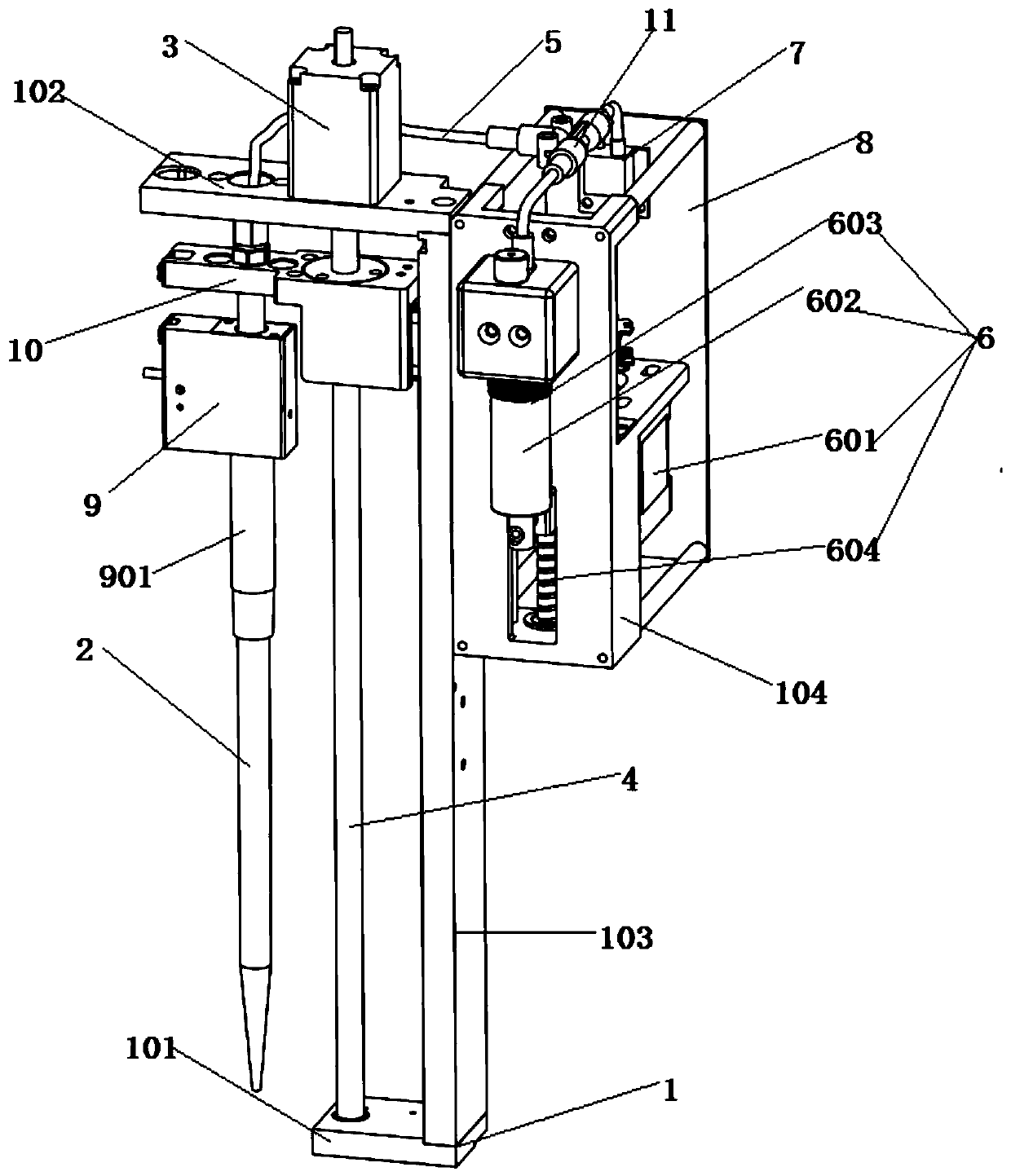

[0026] Such as figure 1 As shown, this embodiment provides a pipetting device that can self-check airtightness and accurately extract, including the following components:

[0027] Frame 1, described frame 1 comprises base 101, upper support plate 102, side support plate 103 and side support 104, and the two ends of described side support plate 103 are connected with described base 101 and described upper support plate 102 respectively , the side bracket 104 is arranged on the side support plate 103;

[0028] A suction mechanism, arranged on the side support 104, is used to suck the sample in the sample container;

[0029] The lifting mechanism is arranged on the upper support plate 102, which includes a second slider 10, which can rise or fall along the height direction of the side support plate 103;

[0030] The pipetting mechanism is arranged on the second slider 10 and is used to pipette the sample in the sample container.

[0031] In this embodiment, preferably, the suc...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment provides a method of operating a pipetting device that can self-test airtightness and accurately extract, including the following steps:

[0040] (1) When drawing a sample, first start the lifting motor 3, and the liquid pipetting mechanism moves down to the designated position above the sample tube under the drive of the lifting motor 3, and then starts the liquid pipetting motor 601. The piston 603 moves downward to generate a suction force, and the gun head 2 sucks the sample under the action of the suction force. During the process of sucking the sample and after the sample is taken, by monitoring the pressure change of the pressure sensor 7, it is known that The amount of the sample drawn, and the numerical value of the sample amount drawn will be displayed by the controller 8;

[0041] (2) When discharging the sample, the piston 603 moves upward to generate a thrust, and the pipetting mechanism discharges the sample in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com