Double-screw type automatic lifting trolley

An automatic lifting and spiral technology, which is applied in the direction of unstacking, transportation and packaging of objects, can solve the problems of worker observation, inconvenient operation, increase of labor intensity of workers, increase of equipment cost, etc., and achieve compact overall structure layout, reduce Labor intensity of workers, the effect of reducing the cost of the whole line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention adopts the internal and external double screw lifting mechanism, which solves the problem of large-stroke lifting of the stack lifting trolley in the limited working height space, and meets the demand for automatic feeding of large-scale high-speed stamping lines.

[0018] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

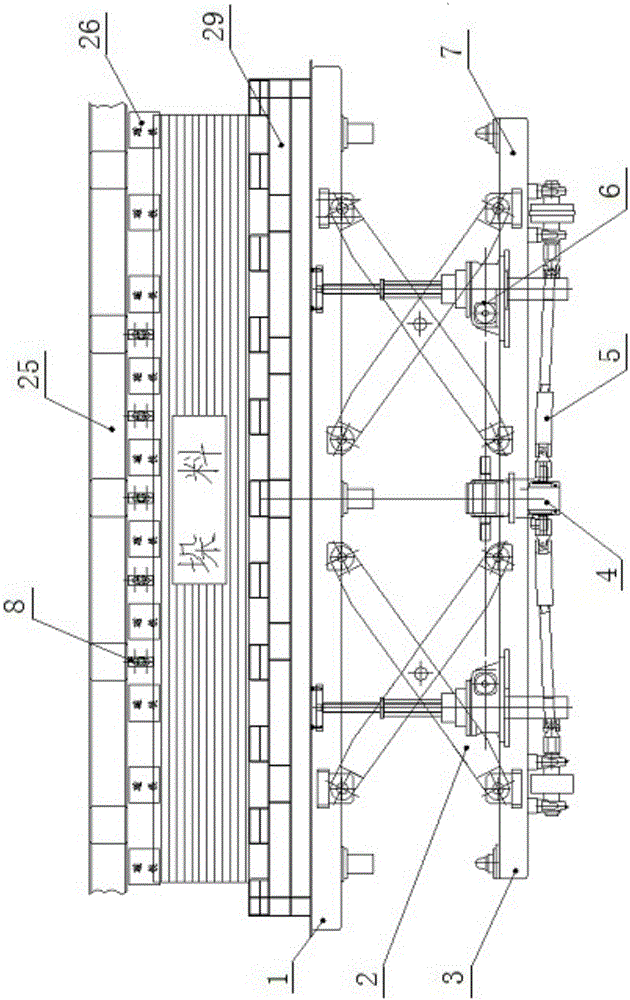

[0019] figure 1 Shown is a schematic front view of the structure of the present invention.

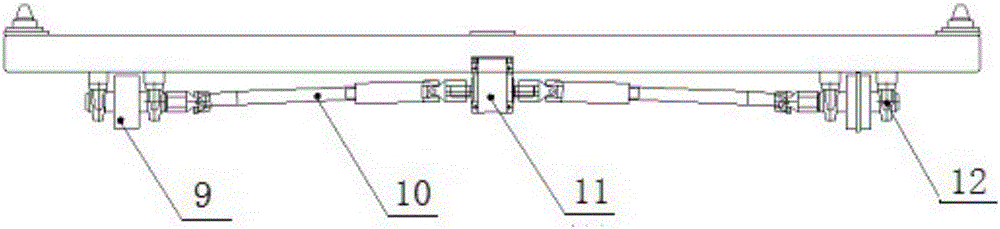

[0020] figure 2 Shown is a schematic top view of the structure of the present invention.

[0021] The present invention includes a vehicle body, a running device 4 , a lifting device 6 and a photoelectric switch 8 .

[0022] The car body includes a top cover 1 , a scissor guide and a base 3 .

[0023] The top cover 1 is used for carrying racks and piles.

[0024] The scissor-type guide device plays a guiding and balancing role when the trolley is lifted; the scissor-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com