Preparation method and application of recombined tobacco additive

A technology for reconstituting tobacco leaves and additives, which can be applied in the fields of application, tobacco, and tobacco treatment, and can solve the problems of heavy wood-like miscellaneous gas, burning sensation, and irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

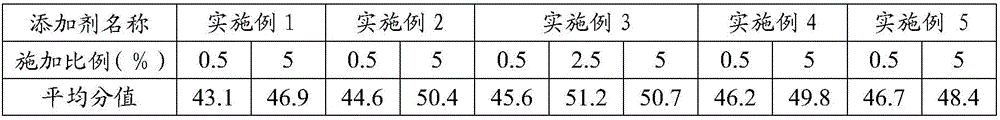

Examples

Embodiment 1

[0034] A preparation method for an additive for recombined tobacco leaves, comprising the steps of:

[0035] Step 1, preparing valerian root extract

[0036] 1) Cut valerian root into flakes smaller than 1cm×1cm×0.3cm and grind it into powder, take 40 mesh powder for extraction; 2) Press valerian root powder: 95% alcohol: water: sorbitol = 100: 45: 300 ︰ Mass ratio of 15 is followed by adding water, 95% alcohol, sorbitol, and valerian root powder into the extraction tank for reflux extraction, and the reflux time is 3 hours; 3) the solution is filtered through a 100-mesh sand core funnel to obtain a brown-red filtrate, and the filter residue Discard; 4) Add 1 times the volume of water to the filtrate, stir evenly and let stand for 24 hours; 5) Take the supernatant and concentrate to 1 / 9 of the volume of the supernatant to obtain the valerian root extract, with a relative density of 1.05;

[0037] Step 2. Mix the valerian root extract prepared in step 1 and other raw material ...

Embodiment 2

[0039] A preparation method for an additive for recombined tobacco leaves, comprising the steps of:

[0040] Step 1, preparing valerian root extract

[0041] 1) Cut valerian root into flakes smaller than 1cm×1cm×0.3cm and grind it into powder, take 40 mesh powder for extraction; 2) According to valerian root powder: 95% alcohol: water: sorbitol = 100: 60: 300 ︰The mass ratio of 12 is followed by adding water, 95% alcohol, sorbitol, and valerian root powder into the extraction tank for reflux extraction, and the reflux time is 3 hours; 3) Filter the solution through a 100-mesh sand core funnel to obtain a brown-red filtrate, and the filter residue Discard; 4) Add 2 times the volume of water to the filtrate, stir evenly and let stand for 24 hours; 5) Take the supernatant and concentrate to 1 / 6 of the volume of the supernatant to obtain the valerian root extract, with a relative density of 1.2;

[0042]Step 2. Mix the valerian root extract prepared in step 1 and other raw materi...

Embodiment 3

[0044] A preparation method for an additive for recombined tobacco leaves, comprising the steps of:

[0045] Step 1, preparing valerian root extract

[0046] 1) Cut valerian root into flakes smaller than 1cm×1cm×0.3cm and grind it into powder, take 55 mesh powder for extraction; 2) Press valerian root powder: 95% alcohol: water: sorbitol = 100: 70: 300 ︰ Mass ratio of 15 is followed by adding water, 95% alcohol, sorbitol, and valerian root powder into the extraction tank for reflux extraction, and the reflux time is 3 hours; 3) the solution is filtered through a 100-mesh sand core funnel to obtain a brown-red filtrate, and the filter residue Discard; 4) Add 3 times the volume of water to the filtrate, stir evenly and let stand for 24 hours; 5) Take the supernatant and concentrate to 1 / 5 of the volume of the supernatant to obtain the valerian root extract with a relative density of 1.1;

[0047] Step 2. Mix the valerian root extract prepared in step 1 and other raw material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com