H-shaped steel and concrete composite pile and construction method thereof

A technology of H-shaped steel and concrete, which is applied in sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of convenient construction, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

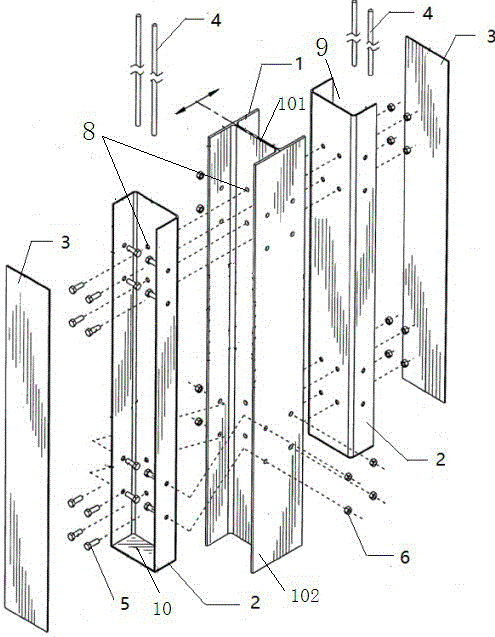

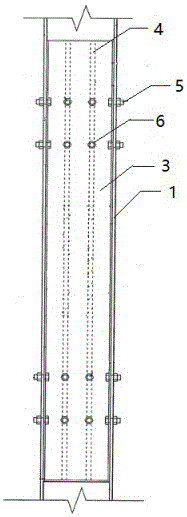

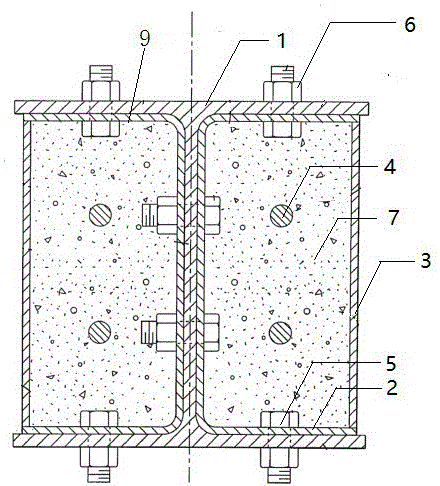

[0027] Such as Figure 1~3 As shown, a kind of composite pile that adopts H-shaped steel and concrete in the present embodiment includes an H-shaped steel 1, two channel steels 2, closed steel plates 3, two pairs of vertical steel bars 4 and nuts 6, some screw rods 5, H There are bolt openings 8 at the web and flange of the shaped steel pile, and there is a channel steel 2 perpendicular to the web, the long side of which is slightly shorter than the web length of the H-shaped steel 1, and the leg width is 1-2 cm smaller than the flange , and embedded in the web groove of H-shaped steel 1, the channel steel 2 is fixed on the H-shaped steel plate 1 through bolt connection, its notch is sealed by a closed steel plate 3, and placed vertically in the channel steel 2 Rebar 4, then concrete 7.

[0028] The bottom surfaces of the two channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com