Noise reduction mechanism and sound barrier plate thereof

A technology of noise reduction and noise reduction cavity, which is applied in the direction of noise absorption devices, buildings, etc., can solve the problems of not being able to form product diversification, affecting the sound absorption effect, and the weather changes of the sound-absorbing cotton have a great influence, and achieve a variety of products. The effect of improving sound absorption, increasing sound absorption area, and good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

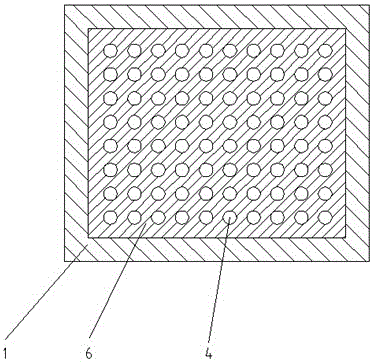

[0028] Figures 1 and 4 show the first embodiment of the present invention: a noise reduction mechanism and a sound barrier plate thereof, including a closed noise reduction cavity surrounded by a top plate 3, a side plate 1 and a bottom plate 2, and the A noise reduction component 5 is provided in the noise chamber, and several sound absorption holes 4 penetrating the top plate 3 are provided on the top plate 3, which can absorb the generated sound into the noise reduction mechanism, so that the noise reduction mechanism can perform noise reduction processing on the sound.

[0029] The sound-absorbing holes 4 are equal in size and arranged at equal intervals, so that the sound can be evenly absorbed into the noise-reducing cavity, so as to better attenuate and reduce the noise.

[0030] The noise reduction component 5 is a plurality of irregularly shaped cells 7 of different sizes, which can better reflect and weaken the absorbed sound to achieve the effect of noise reduction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com