A kind of diatomite composite material and preparation method thereof

A technology of composite materials and diatomite, which is applied in the field of building materials, can solve the problems of large thermal conductivity of thermal insulation materials, high water absorption rate of thermal insulation materials, and restrictions on the application of diatomite, so as to reduce thermal conductivity, solve high water absorption rate and high strength. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

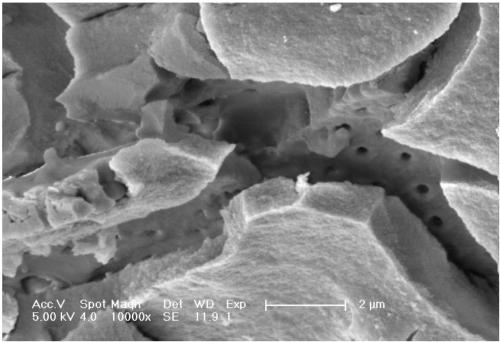

[0037] The present invention also provides a method for preparing the above-mentioned diatomite composite material, comprising: S1) mixing the silicic acid solution with the diatomite, ultrasonically dispersing, adding ammonia water, and polycondensing to obtain the mixture; S2) mixing the After the mixture is gelled, aged, solvent exchanged, surface modified and dried, the diatomite composite material is obtained.

[0038] The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0039] Wherein, the silicic acid solution is preferably prepared according to the following steps: after diluting water glass with water, ion-exchanging with a strongly acidic cation exchange resin to obtain a silicic acid solution.

[0040] Preferably in the present invention water glass is diluted with distilled water; The volume ratio of described water glass and distilled water needn't be fixed, and in the present inve...

Embodiment 1

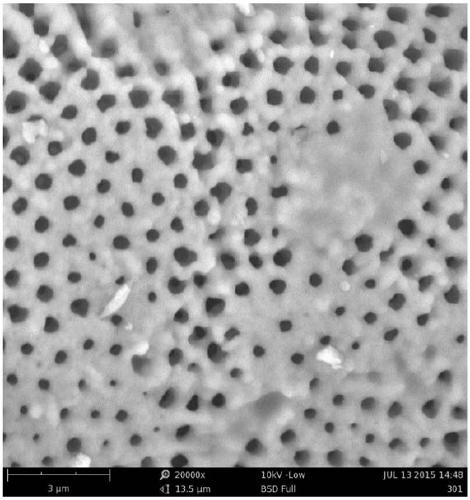

[0054] 1.1 Diatomite is made of diatomite mined from diatomite ore. It has been dried, pulverized, separated and activated before use; the pore size distribution is 200-800nm, the porosity is 85%, and the particle size is 300 mesh. Specific surface area 55m 2 / g.

[0055] 1.2 Take 400mL of water glass, dilute it with 1200mL of distilled water, ion-exchange with strong acid styrene cation exchange resin to obtain silicic acid, add diatomaceous earth in proportion (the volume ratio of diatomite to silicic acid is 2:1), and disperse by ultrasonic.

[0056] 1.3 Add 1 mol / L ammonia water to the mixture obtained in 1.2 to adjust the pH value, catalyze the polycondensation reaction, stir for 3 minutes to make the pH value 4.8, pour it into a polypropylene container and let it stand for 40 minutes to gel, and gel the gelled water gel at room temperature in 50% ethanol / H 2 O solution for 24 hours.

[0057] 1.4 Solvent exchange / surface modifier: At 50°C, modify the aged hydrogel with...

Embodiment 2

[0062] 2.1 Diatomaceous earth is selected from diatomite mines of secondary and tertiary diatomite, which is dried, crushed, separated and activated before use; the pore size distribution is 200-800nm, the porosity is 85%, and the particle size is 300 mesh. Specific surface area 55m 2 / g.

[0063] 2.2 Take 400mL of water glass, dilute with 1600mL of distilled water, ion-exchange with strong acid styrene cation exchange resin to obtain silicic acid, add diatomaceous earth in proportion (the volume ratio of diatomite to silicic acid is 1:5), and disperse by ultrasonic.

[0064] 2.3 Add 1mol / L ammonia water to the above mixture to adjust the pH value, catalyze the polycondensation reaction, stir for 3 minutes to make the pH value 5.2, pour it into a polypropylene container and let it stand for gelation for 30 minutes, and then gel the gelled diatomaceous earth gel at room temperature in 50% ethanol / H 2 O solution for 24 hours.

[0065] 2.4 Solvent exchange / surface modifier: In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com