Preparation method of antibacterial nanofiber air filtering material

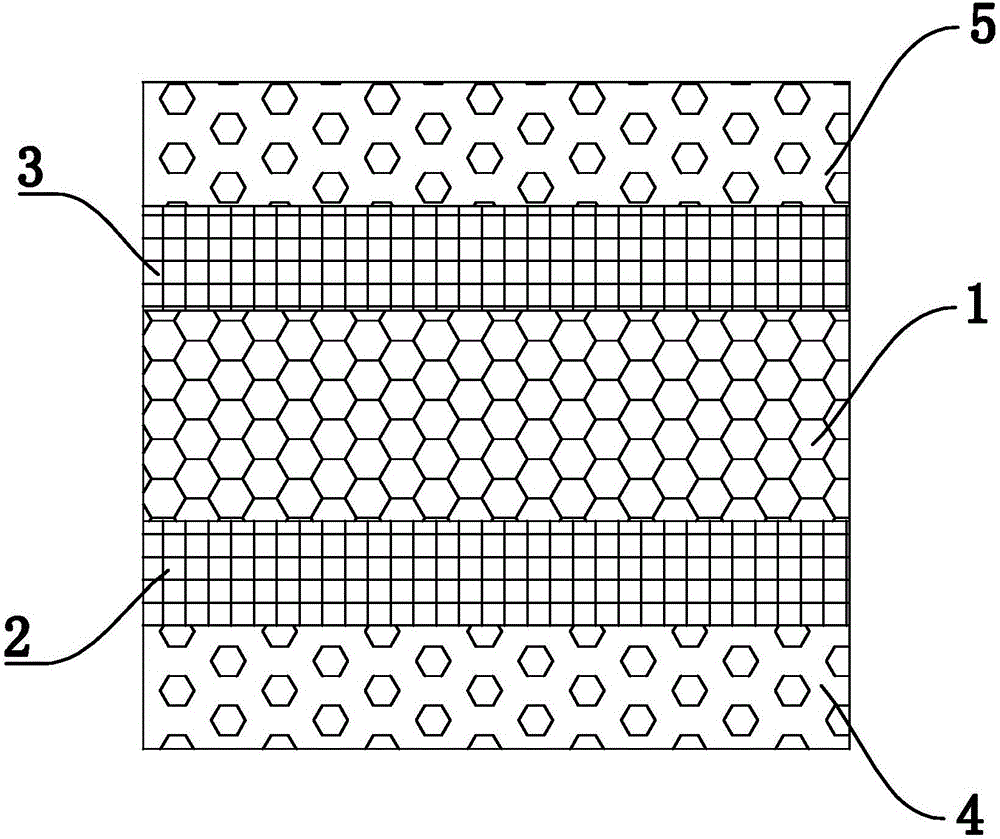

An air filter material and nanofiber technology, applied in fiber processing, chemical instruments and methods, filament/thread forming, etc., can solve the problems of weak antibacterial performance and comfort performance, insignificant antibacterial performance, and easy blocking of micropores. , to achieve the effect of good biocompatibility, good permeability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

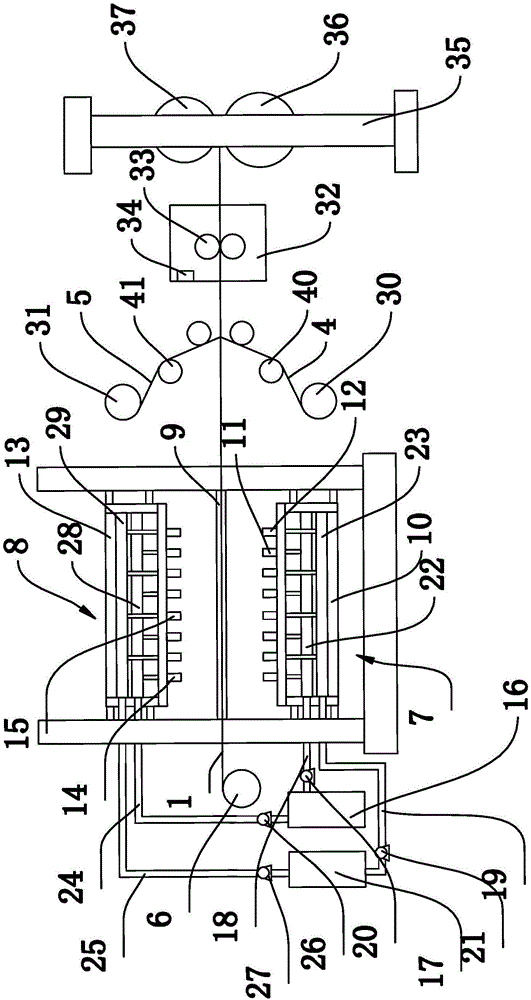

Method used

Image

Examples

Embodiment 1

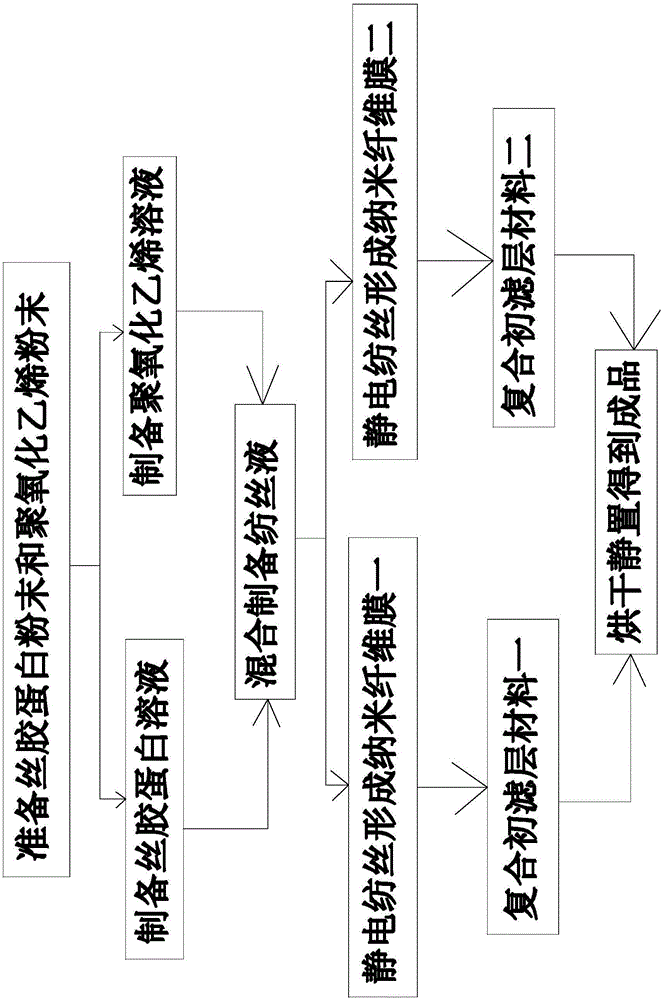

[0044] A preparation method of nanofiber air filter material, the specific steps are:

[0045] S1: Prepare sericin powder and polyethylene oxide powder, and divide them into multiple parts according to different mass parts;

[0046] S2: dissolving the first portion of sericin powder in deionized water, and then placing it on a heating magnetic stirrer for 10 hours at constant temperature and stirring until completely dissolved to form a homogeneous solution with a mass fraction of 30%; Dissolving the second portion of sericin powder in deionized water, and then placing it in a heating magnetic stirrer and stirring at constant temperature for 12 hours to form a homogeneous solution with a mass fraction of 40%;

[0047] S3: Dissolve the first polyoxyethylene powder in deionized water, then place it on a heating magnetic stirrer and stir it at constant temperature for 8 hours to form a homogeneous solution with a mass fraction of 20%; the second One part of polyethylene oxide po...

Embodiment 2

[0067] A preparation method of nanofiber air filter material, the specific steps are:

[0068] S1: Prepare sericin powder and polyethylene oxide powder, and divide them into multiple parts according to different mass parts;

[0069] S2: dissolving the first portion of sericin powder in deionized water, and then placing it on a heating magnetic stirrer for 12 hours at constant temperature and stirring until completely dissolved to form a homogeneous solution with a mass fraction of 45%; Dissolving the second portion of sericin powder in deionized water, and then placing it in a heating magnetic stirrer and stirring at constant temperature for 13 hours to form a homogeneous solution, the mass fraction of which is 50%;

[0070] S3: Dissolve the first polyoxyethylene powder in deionized water, then place it on a heating magnetic stirrer and stir it at a constant temperature for 10 hours to form a homogeneous solution, and the mass fraction of the homogeneous solution is 30%; the s...

Embodiment 3

[0090] A preparation method of nanofiber air filter material, the specific steps are:

[0091] S1: Prepare sericin powder and polyethylene oxide powder, and divide them into multiple parts according to different mass parts;

[0092] S2: dissolving the first portion of sericin protein powder in deionized water, and then placing it on a heating magnetic stirrer and stirring at constant temperature for 14 hours until completely dissolved to form a homogeneous solution with a mass fraction of 50%; Dissolving the second portion of sericin powder in deionized water, and then placing it in a heating magnetic stirrer and stirring at constant temperature for 15 hours to form a homogeneous solution with a mass fraction of 60%;

[0093] S3: Dissolve the first polyoxyethylene powder in deionized water, then place it on a heating magnetic stirrer and stir it at a constant temperature for 12 hours to form a homogeneous solution with a mass fraction of 35%; the second Dissolve one part of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com