Construction technology of cantilever beam push-pull frame for jack-up drilling platform

A drilling platform and cantilever beam technology, applied in the drilling platform field, can solve the problems of manpower and material resources, inconvenient processing and high cost, and achieve the effects of reducing deformation, processing cost and processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention discloses a construction technology for a cantilever beam push-pull frame of a self-elevating drilling platform. The main steps are as follows:

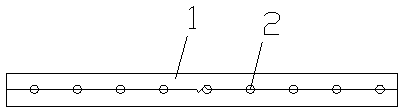

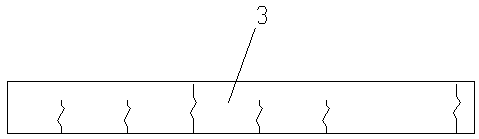

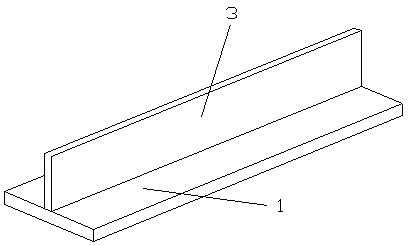

[0023] (1) Material preparation: CNC cut the main board 1 and web 3 of the push-pull frame, add 8mm allowance on one side at the long closing opening in the length direction, and add 30mm allowance at the T row closing opening; in the width direction , a 10mm margin is added on one side; a 27mm margin is added to the radial direction of the pin hole 2. Such as figure 1 , figure 2 shown.

[0024] (2) Lengthening of main board 1 and web 3: place the components on the horizontal tire frame, butt them two by two, leaving only 3mm of welding shrinkage at the closing mouth, and then open the bevel to adjust the overall straightness and flatness of the components Until it meets the requirements, then fix it with Karma. When welding, one side is grounded first, the other side is followed by root cleaning, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com