A movable support for oxygen welding equipment

A mobile and equipment technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as fire, increased oxygen or acetylene gas leakage, damage, etc., and achieve the effect of flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

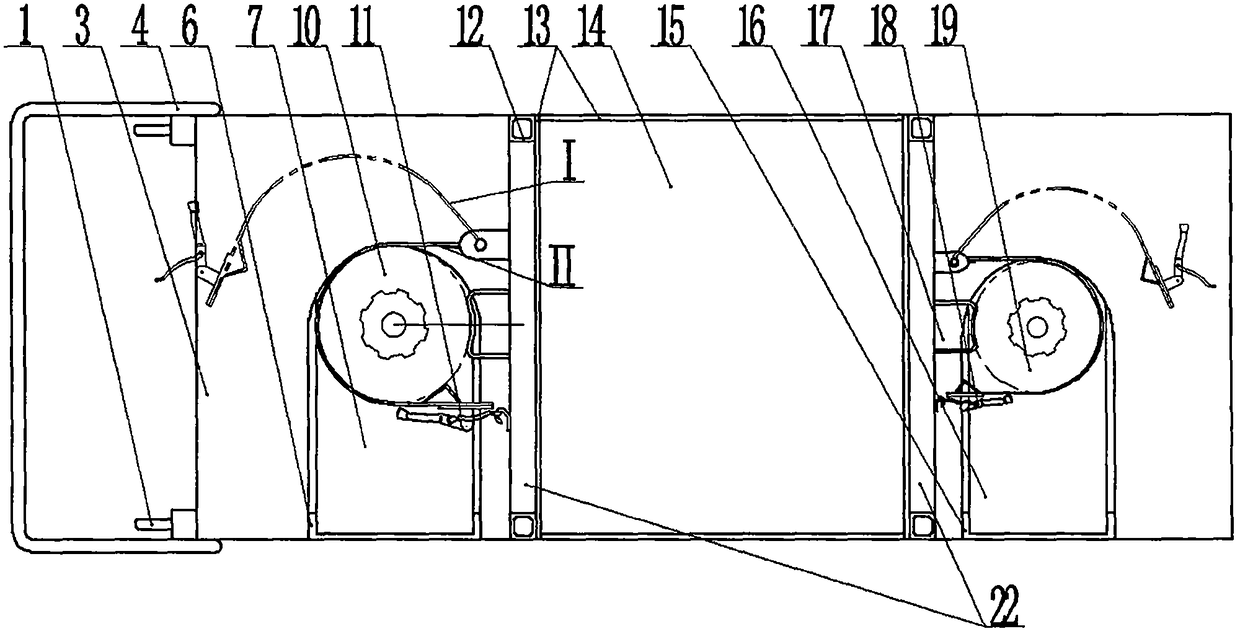

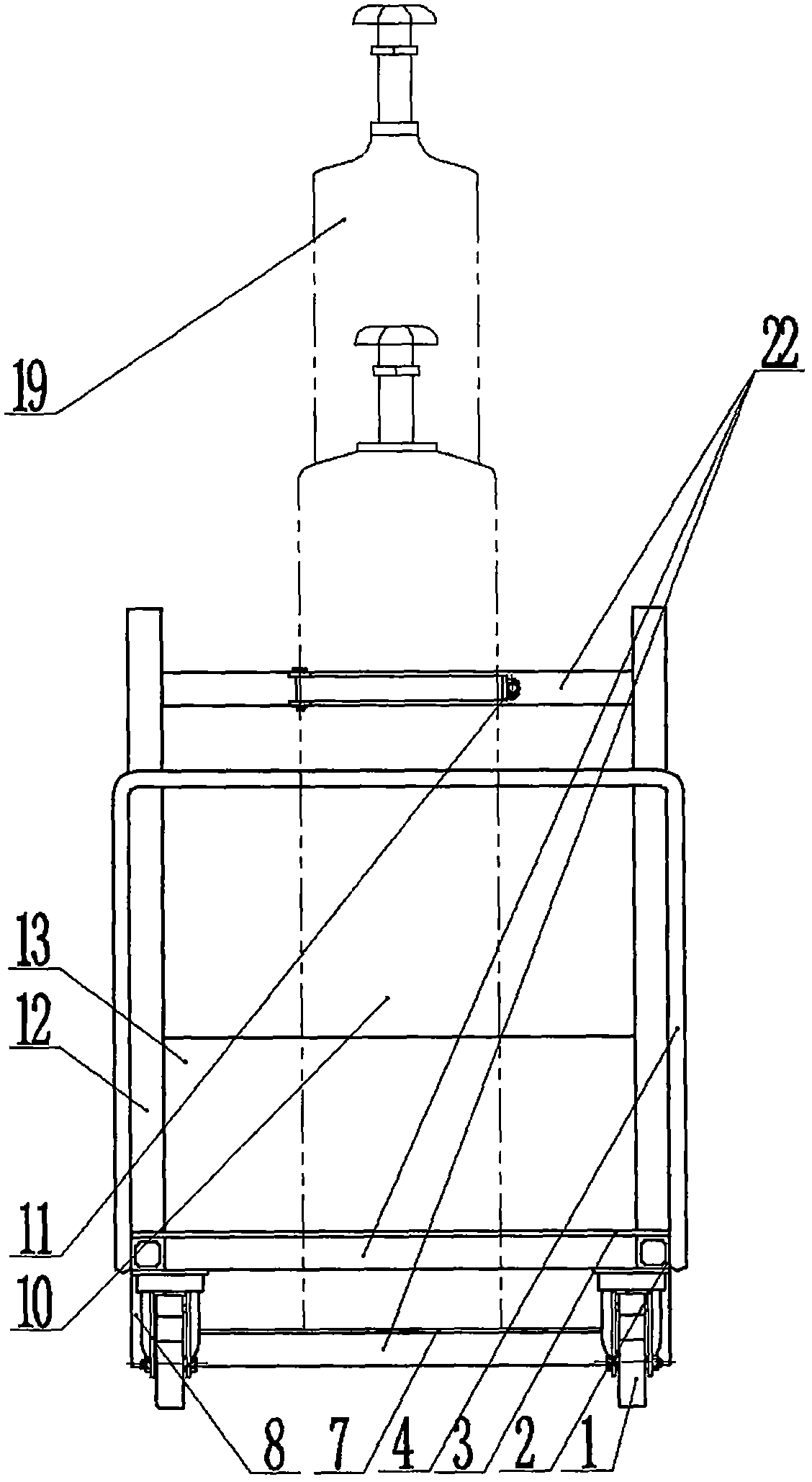

[0025] A detailed description will be given below in conjunction with the accompanying drawings.

[0026] Such as Figure 1~4 Shown, the object supported by the support---the acetylene gas cylinder 10, the oxygen cylinder 19 represent with two-dot dash line, do transparent processing. The movable support of this oxygen welding equipment provided by the present invention, the frame at the bottom of the support is welded by two longitudinal beams and ten cross beams 22, and the longitudinal beam is formed by blanking a square steel pipe with a left end 2, Four vertical parts 8, an acetylene gas cylinder support beam 6, a middle straight beam 9, an oxygen cylinder support beam 15 and a right end 20 groups are welded into a shape with two sections of concaves; and at the left end The triangular reinforcing plate 5 that a piece of steel plate is welded respectively between head 2 and vertical member 8, two vertical members 8 and middle straight beam 9 and vertical member 8 and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com