Gradient tungsten-copper composite and preparation method thereof

A composite material, tungsten-copper technology, applied in the field of gradient tungsten-copper composite material and its preparation, can solve problems such as no application, avoid forming cracks, ensure strength and precision, and improve conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

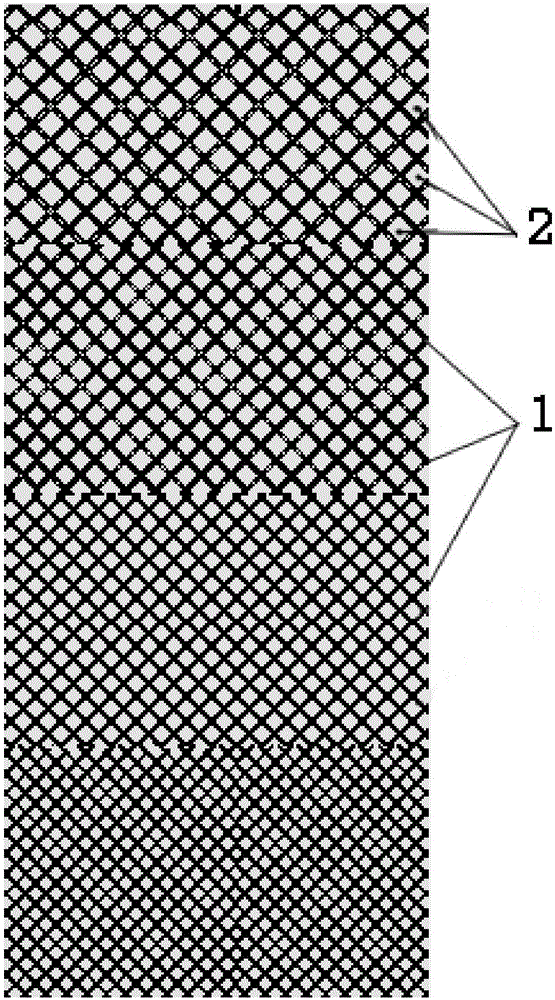

[0032] Such as figure 1 As shown, the gradient tungsten-copper composite material in this embodiment includes a tungsten skeleton 1 made by electron beam selective melting molding method and a copper filling phase 2 made by infiltration method. The tungsten skeleton 1 is arranged in multiple layers along its height direction. Each layer of tungsten skeleton 1 has a network porous structure, and the copper filling phase 2 is filled in the pores of each layer of tungsten skeleton 1, and the volume percentage of copper filling phase 2 increases or decreases layer by layer.

[0033] Such as figure 1 As shown, in the gradient tungsten-copper composite material of this embodiment, the tungsten skeleton 1 is represented by a grid-shaped black solid line, and the copper-filled phase 2 is represented by a gray filling color.

[0034] In this embodiment, the number of layers of the tungsten skeleton 1 is four layers, and the four-layer tungsten skeleton 1 is neatly stacked in the heigh...

Embodiment 2

[0048] Such as figure 1 As shown, the gradient tungsten-copper composite material in this embodiment includes a tungsten skeleton 1 made by electron beam selective melting molding method and a copper filling phase 2 made by infiltration method. The tungsten skeleton 1 is arranged in multiple layers along its height direction. Each layer of tungsten skeleton 1 has a network porous structure, and the copper filling phase 2 is filled in the pores of each layer of tungsten skeleton 1, and the volume percentage of copper filling phase 2 increases or decreases layer by layer.

[0049] Such as figure 1 As shown, in the gradient tungsten-copper composite material of this embodiment, the tungsten skeleton 1 is represented by a grid-shaped black solid line, and the copper-filled phase 2 is represented by a gray filling color.

[0050] In this embodiment, the number of layers of the tungsten skeleton 1 is four layers, and the four-layer tungsten skeleton 1 is neatly stacked in the heigh...

Embodiment 3

[0064] Such as figure 1 As shown, the gradient tungsten-copper composite material in this embodiment includes a tungsten skeleton 1 made by electron beam selective melting molding method and a copper filling phase 2 made by infiltration method. The tungsten skeleton 1 is arranged in multiple layers along its height direction. Each layer of tungsten skeleton 1 has a network porous structure, and the copper filling phase 2 is filled in the pores of each layer of tungsten skeleton 1, and the volume percentage of copper filling phase 2 increases or decreases layer by layer.

[0065] Such as figure 1 As shown, in the gradient tungsten-copper composite material of this embodiment, the tungsten skeleton 1 is represented by a grid-shaped black solid line, and the copper-filled phase 2 is represented by a gray filling color.

[0066] In this embodiment, the number of layers of the tungsten skeleton 1 is four layers, and the four-layer tungsten skeleton 1 is neatly stacked in the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com