Automatic prebaked anode carbon block ungrouping and cleaning unit

A prebaked anode and carbon block technology, which is applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of poor processing effect, low automation degree and work efficiency, high safety factor, etc., and achieve good sharpness , Improve work efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058]Since it was put into use in Shandong Aohai Group in August 2016, the effect has been remarkable. The current annual output of Shandong Aohai Group is 600,000 tons. The original manual cleaning required 90 people, but now only 18 people are used for cleaning with this equipment; the cost of manual cleaning is 16 yuan / ton, and the cleaning cost of this equipment is less than 6 yuan / ton. The production cost per ton of product has been reduced by more than 10 yuan, which has greatly reduced the production cost of the enterprise, and at the same time effectively improved the production environment, which has been highly praised by users.

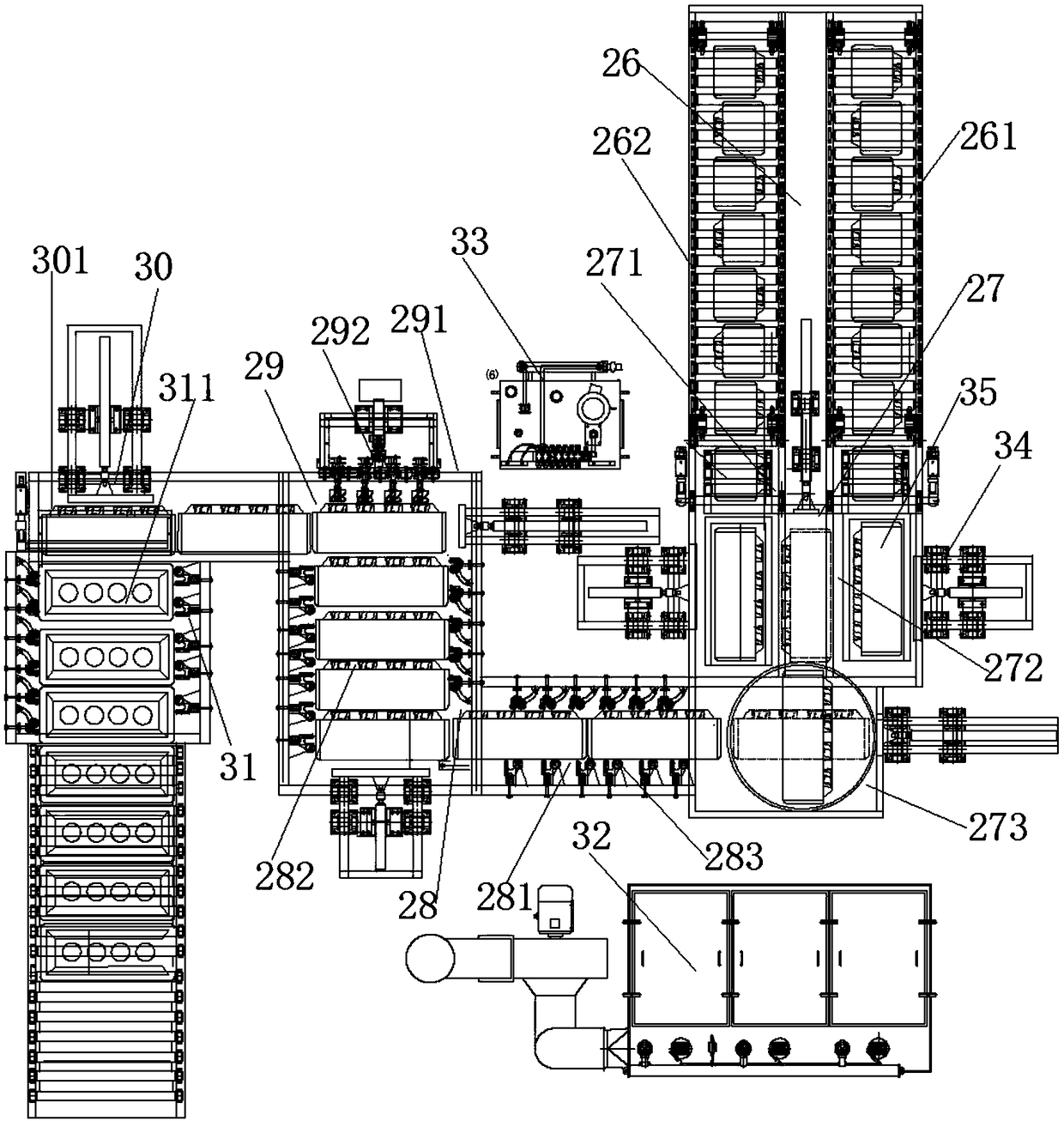

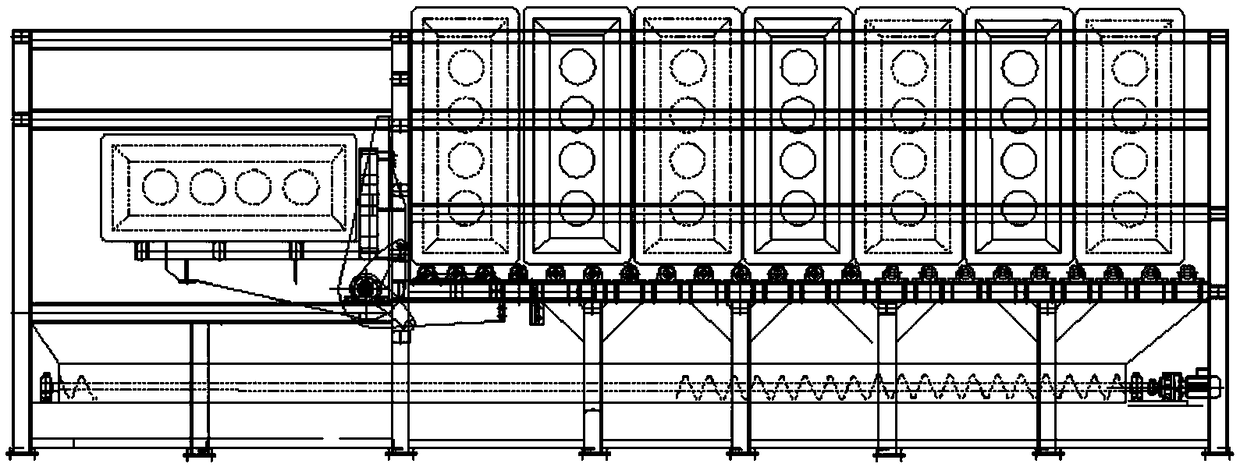

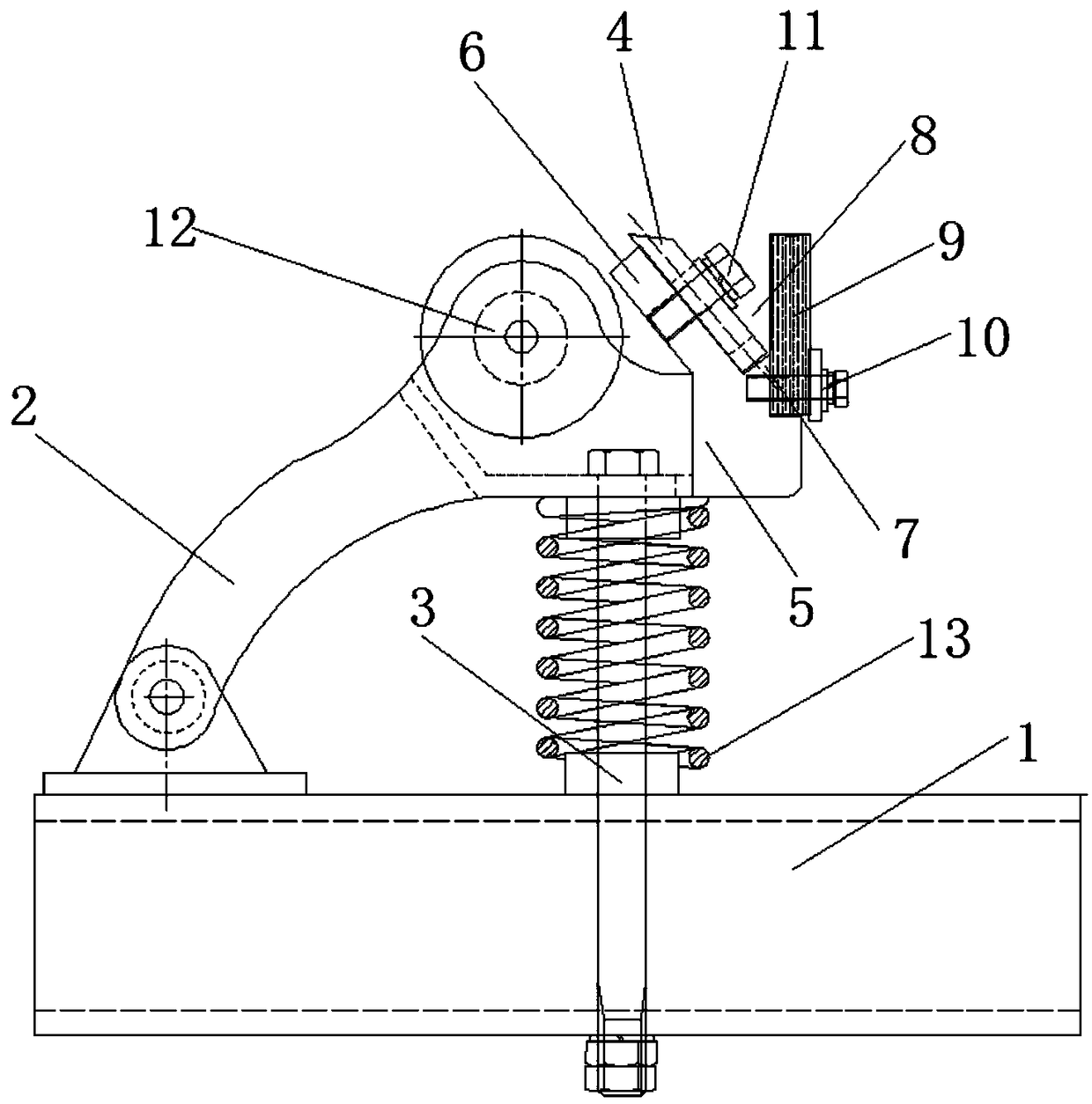

[0059] The present invention adopts fully automatic ungrouping and cleaning of the filler particles adhering to the surface of the prebaked anode and the rod hole. The innovation of this fully automatic prebaked anode cleaning unit is that it integrates the ungrouping and cleaning of the anode carbon block 35, adopts multi-layer high-stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com