A kind of toner pipeline dredging device

A pipeline and carbon gun technology, which is applied in the field of toner pipeline dredging devices, can solve the problems of slow drop of negative pressure pressure, failure to dredging pipelines successfully, reducing dredging effect, etc., so as to improve efficiency and success rate, and ensure dredging effect and quality. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

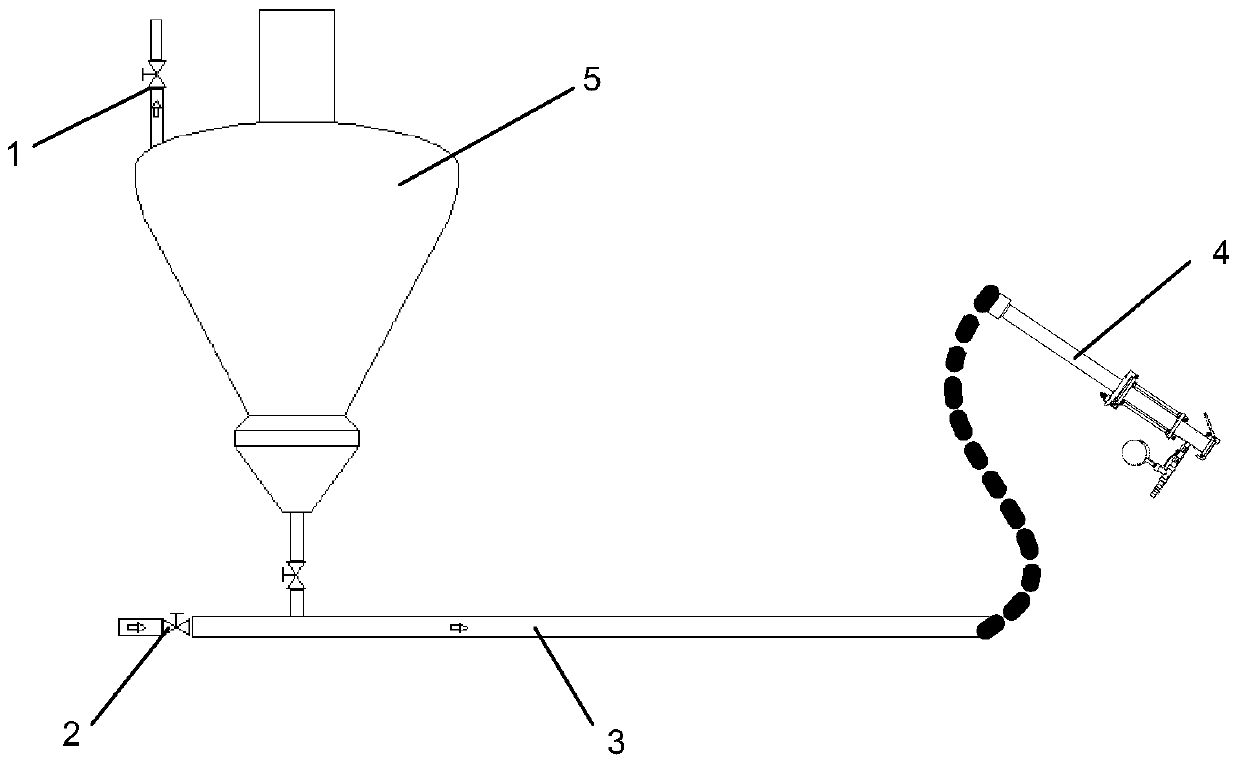

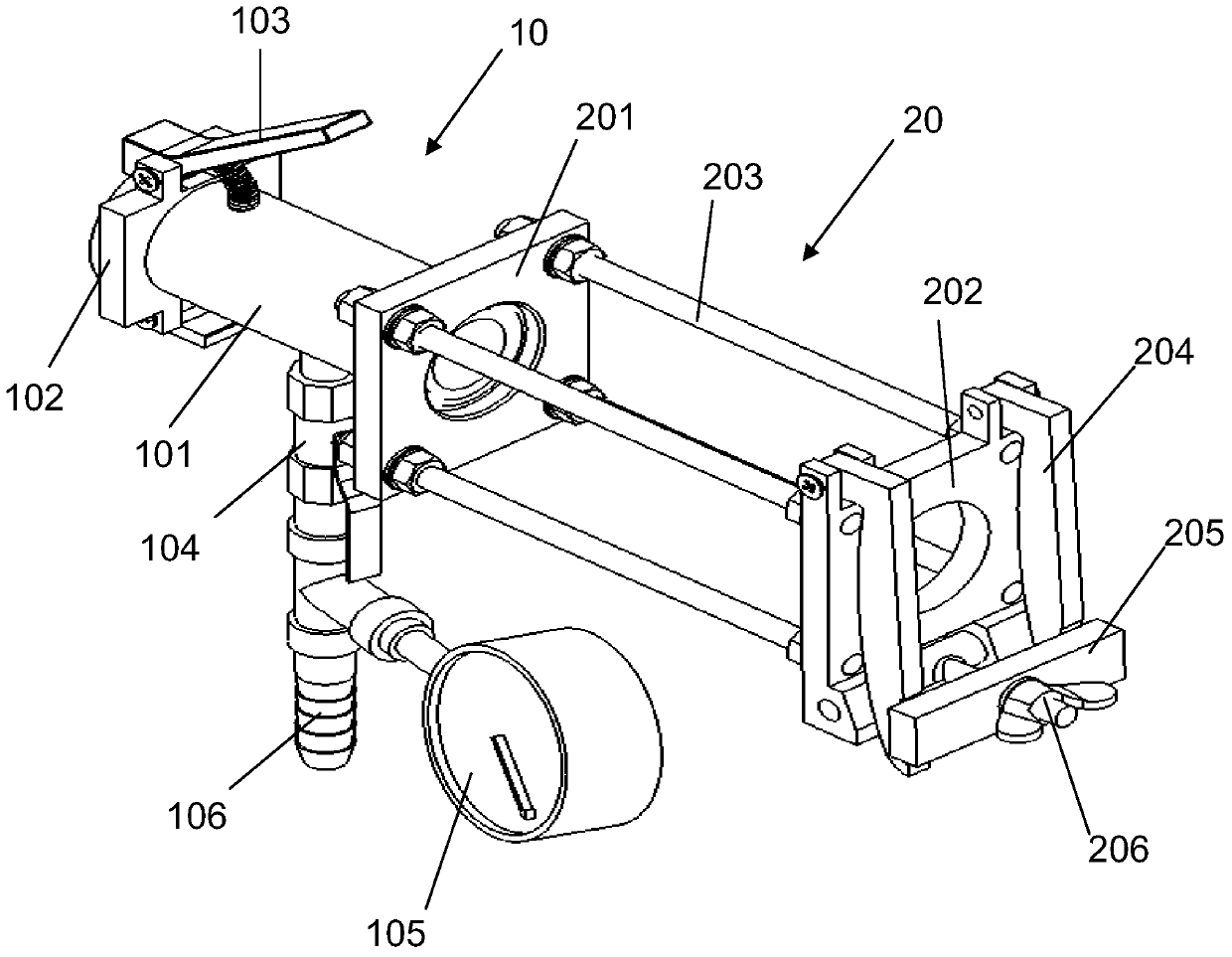

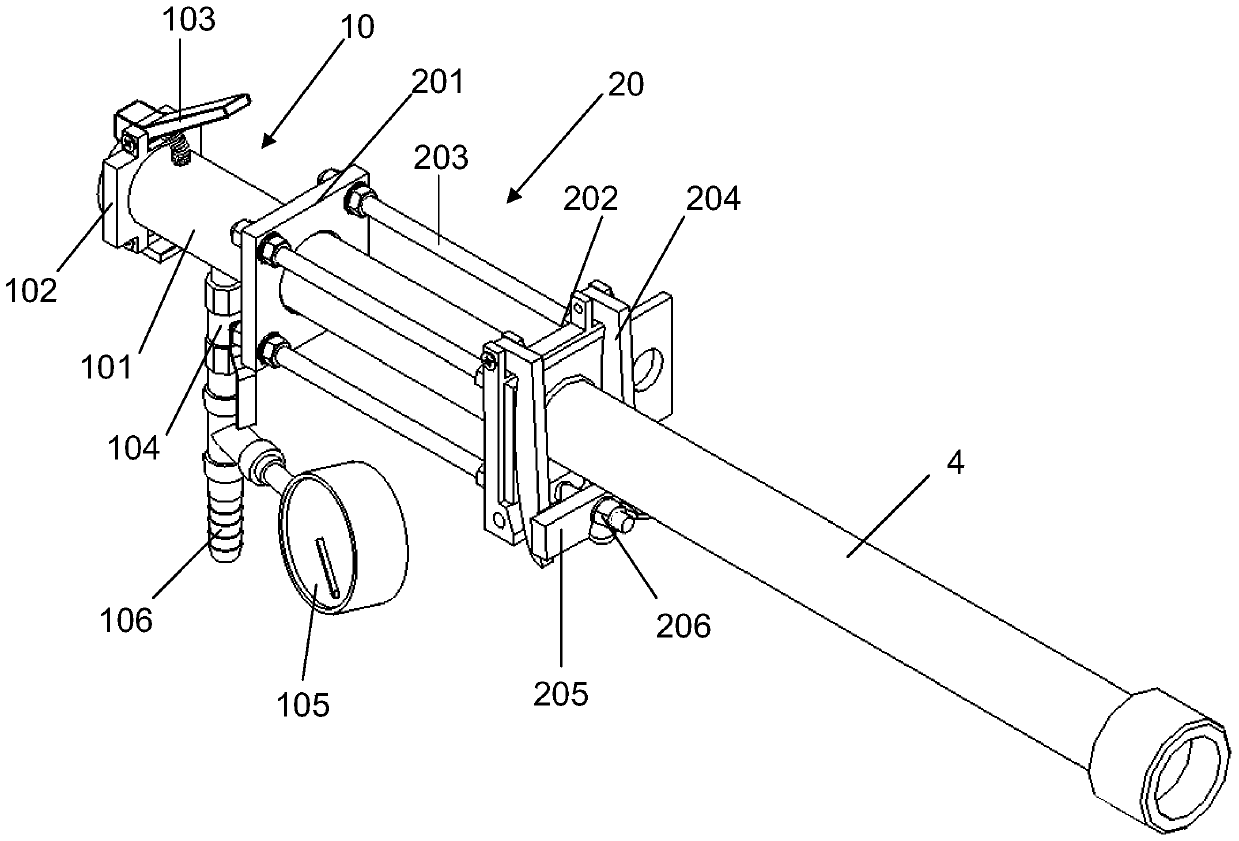

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] combine Figures 2 to 6 As shown, the present invention includes a clamping mechanism 20 and a release mechanism 10, the clamping mechanism 20 is used to clamp the movable end of the carbon gun, and the release mechanism 10 includes a release cavity 101, an end cover 102, a spring pressure rod 103, and the release cavity The front end of 101 is fixedly connected with the clamping mechanism 20 and communicated with the carbon gun. The end cover 102 is movable at the rear end of the release cavity 101, and the spring pressure rod 103 is pressed on the top of the end cover 102, and is used to control the opening and closing of the end cover 102 to release The cavity 101 is also communicated with a compressed air inlet branch pipe.

[0029] Described clamping mechanism 20 comprises mounting frame and clamping part, and mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com