Wet desulfurization flue gas treatment system and treatment method

A flue gas treatment system, wet desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of large power consumption of wet electrostatic precipitators, reduced investment, high operating costs, etc. problem, to achieve the effect of low power consumption, high operating cost, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

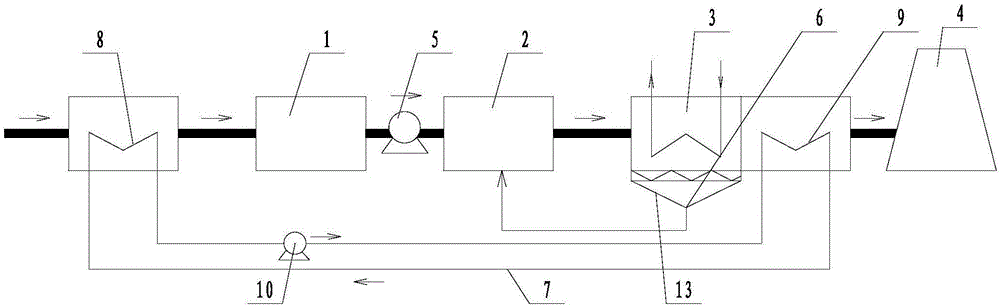

[0024] Example 1: A wet desulfurization flue gas treatment system (see attached figure 1), including electrostatic precipitator 1, wet desulfurization tower 2, wet phase change condensation dust collector 3, chimney 4 arranged in sequence along the flue gas flow direction, and induced draft fan 5 is installed between the electrostatic precipitator and wet desulfurization tower, The lower end of the wet phase change condensation dust collector is provided with a liquid discharge port 6, and the lower end of the wet phase change condensation dust collector is provided with a liquid collection bucket 13, the liquid discharge port is set at the lower end of the liquid collection bucket, and the liquid discharge port is connected to the wet desulfurization tower through a pipeline ; There is a condensation pipe in the wet phase change condensation dust collector, one end of the condensation pipe is connected to a circulation liquid inlet pipe, and the other end of the condensation p...

Embodiment 2

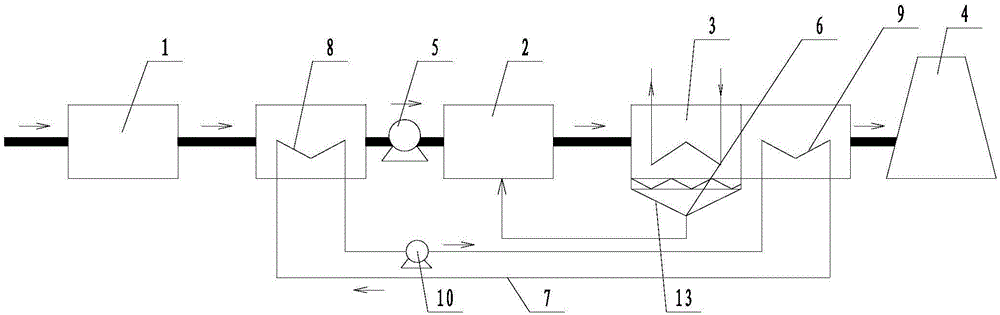

[0026] Example 2: A wet desulfurization flue gas treatment system (see attached figure 2 ), including electrostatic precipitator 1, wet desulfurization tower 2, wet phase change condensation dust collector 3, chimney 4 arranged in sequence along the flue gas flow direction, and induced draft fan 5 is installed between the electrostatic precipitator and wet desulfurization tower, The lower end of the wet phase change condensation dust collector is provided with a liquid discharge port 6, and the lower end of the wet phase change condensation dust collector is provided with a liquid collection bucket 13, the liquid discharge port is set at the lower end of the liquid collection bucket, and the liquid discharge port is connected to the wet desulfurization tower through a pipeline . It also includes a tube heat exchanger, which includes a cooling section and a heating section, the cooling section of the tube heat exchanger is set between the electrostatic precipitator and the ind...

Embodiment 3

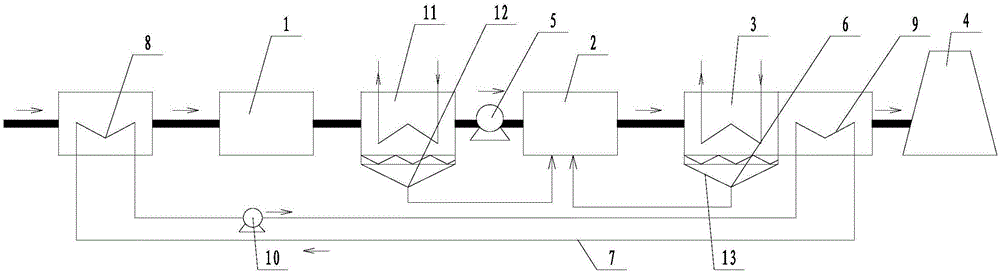

[0028] Example 3: A wet desulfurization flue gas treatment system (see attached image 3 ), including electrostatic precipitator 1, wet desulfurization tower 2, wet phase change condensation dust collector 3, chimney 4 arranged in sequence along the flue gas flow direction, and induced draft fan 5 is installed between the electrostatic precipitator and wet desulfurization tower, The lower end of the wet phase change condensation dust collector is provided with a liquid discharge port 6, the liquid discharge port is arranged at the lower end of the liquid collection bucket, and the liquid discharge port is connected to the wet desulfurization tower through a pipeline. Also includes a tubular heat exchanger 7, the tubular heat exchanger includes a cooling section 8 and a heating section 9, the cooling section of the tubular heat exchanger is set at the front end of the electrostatic precipitator, and the heating section of the tubular heat exchanger is set at the wet The back en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com