Centrifugal automatic oil sludge separation machine

A sludge separation and centrifugal technology, applied in the separation of sediment by centrifugal force, separation method, sedimentation separation, etc., can solve the problems of high cost, inconvenient installation, low degree of automation, etc., to improve product quality, ensure wire drawing speed, cleanliness The effect of increasing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

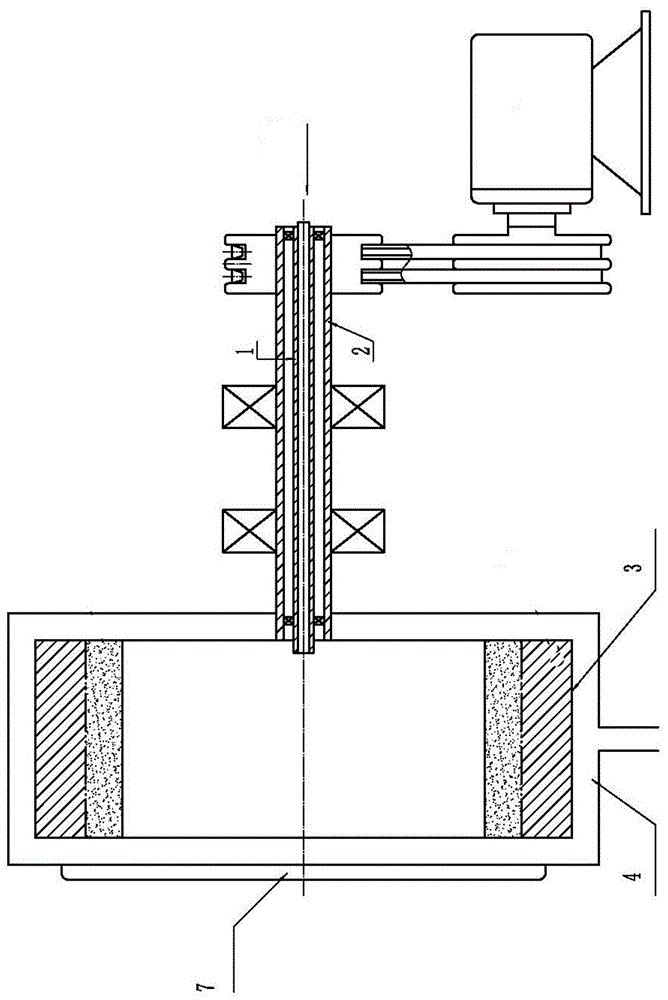

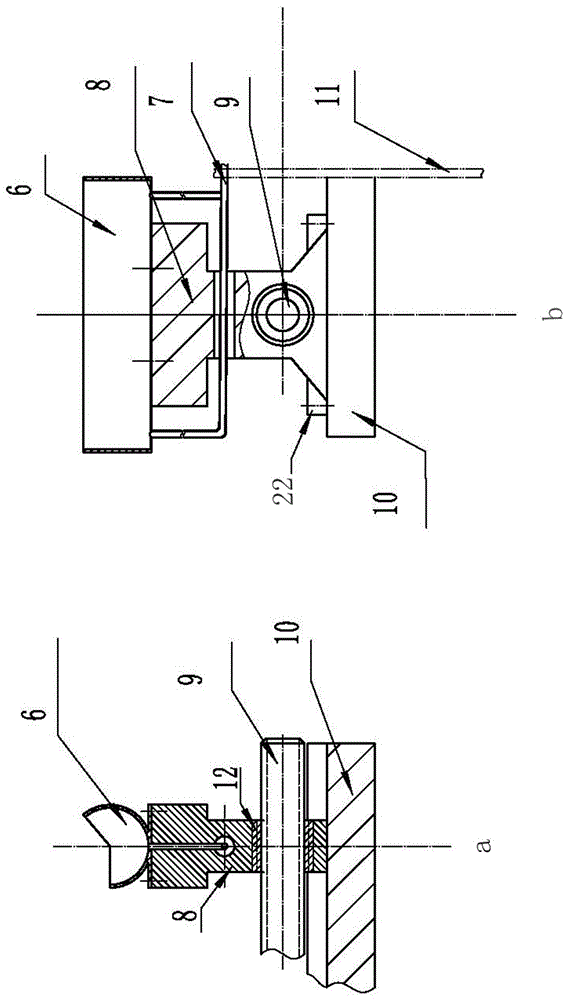

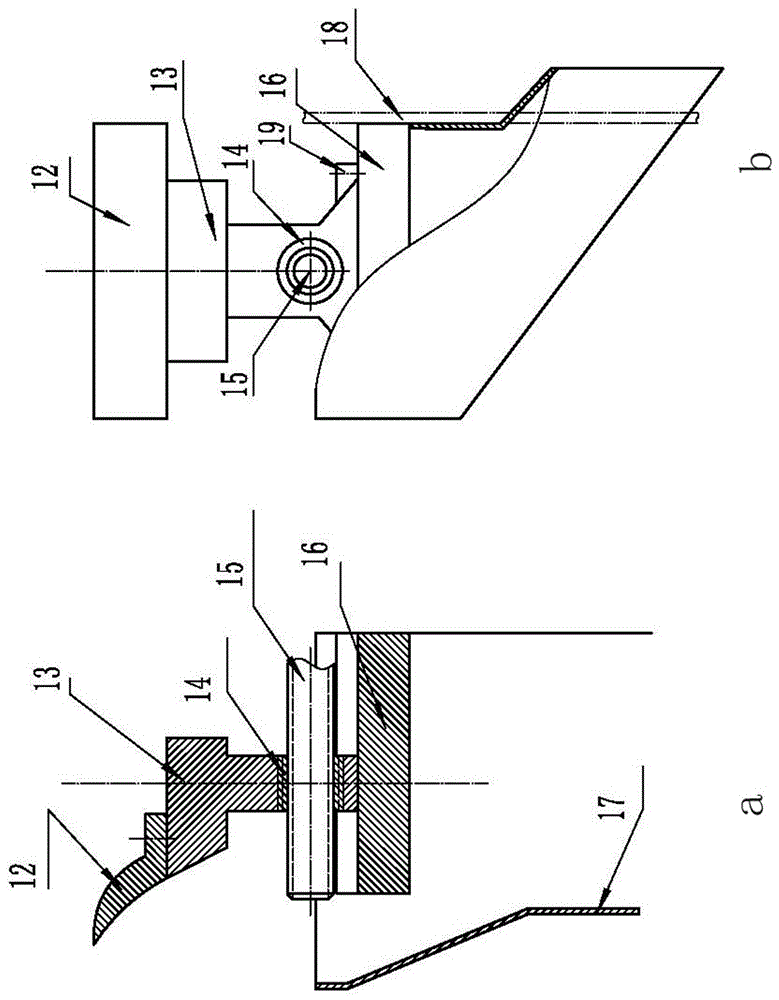

[0051] root tree figure 1 — Figure 4 As shown, a centrifugal automatic sludge separator includes a horizontal drum 3, a protective cover 4 is arranged outside the horizontal drum, the horizontal drum 3 is connected to the power center hollow shaft 2 at one end, and the dirty oil delivery pipe 1 is installed at both ends. Bearings are installed in the hollow shaft 2 of the power center, and the transmission on the hollow shaft 2 of the power center is connected with the power machine. The safety door of the horizontal drum 3 is equipped with a stepping oil scraping device 5 and a stepping scraper shoveling device 6 .

[0052] The protective cover includes a cover body and a safety door.

[0053]The stepping oil scraping device includes: the oil scraping groove 6 is connected with the mobile bracket 8, the screw nut 12

[0054] Link to each other with the hole of mobile support 8, screw mandrel 9 and screw nut 12 link to each other, oil guide pipe 7 is arranged in the mobile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com