Coating system for coating objects

A technology of painting and objects, applied in the field of painting systems, which can solve the problems of pressure loss, difficulty, volume reproducibility and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

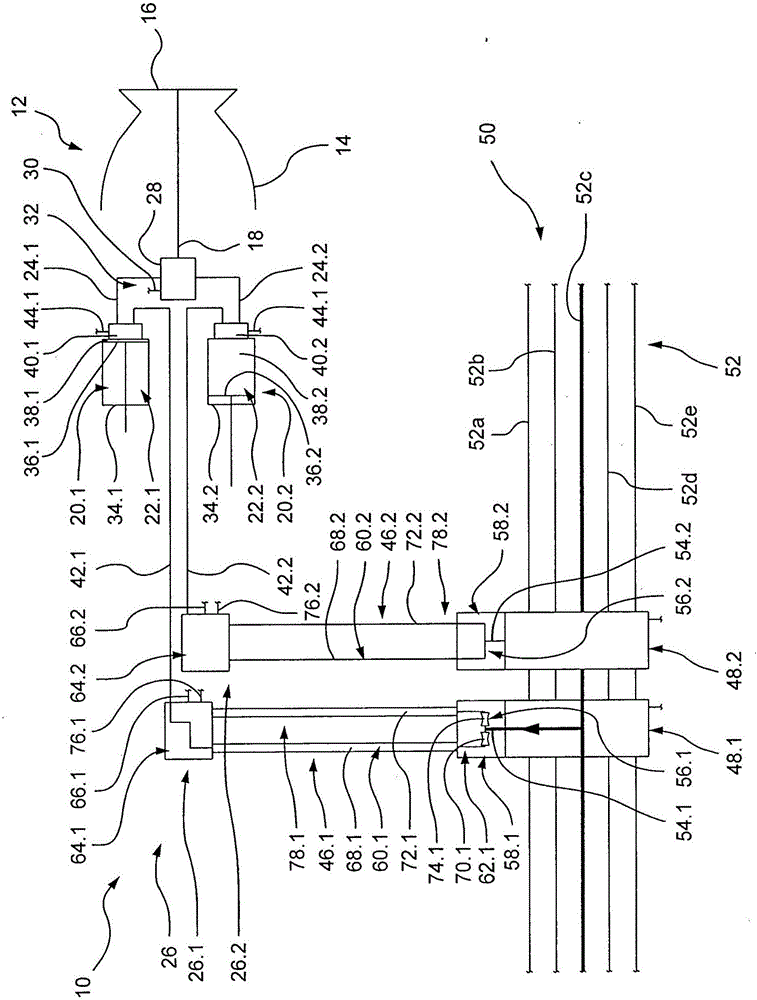

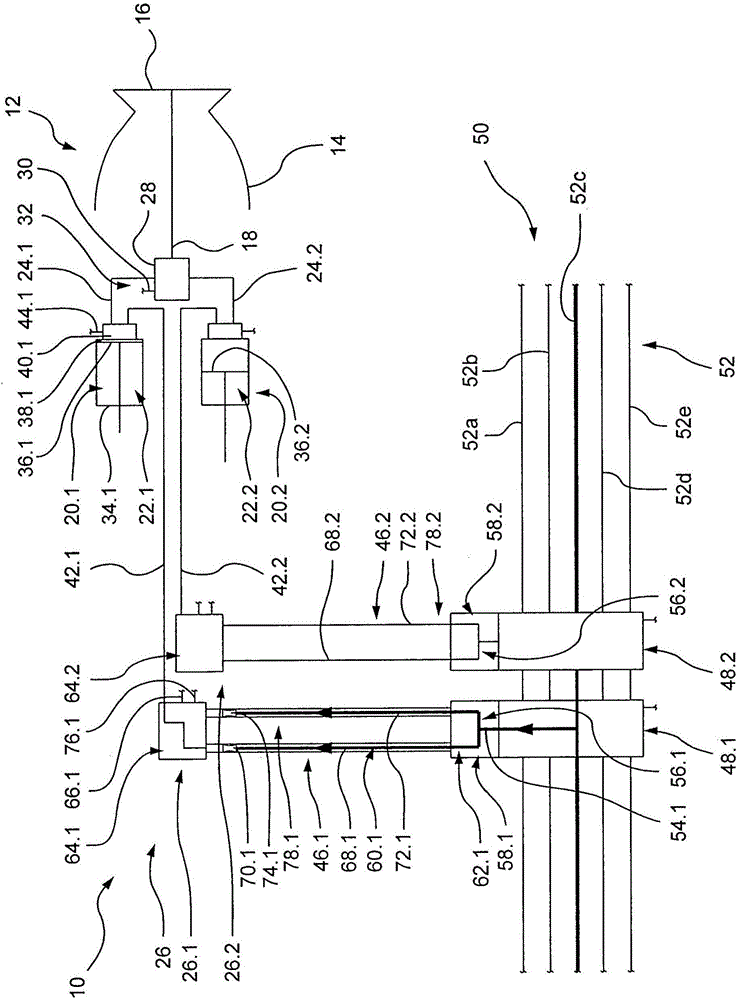

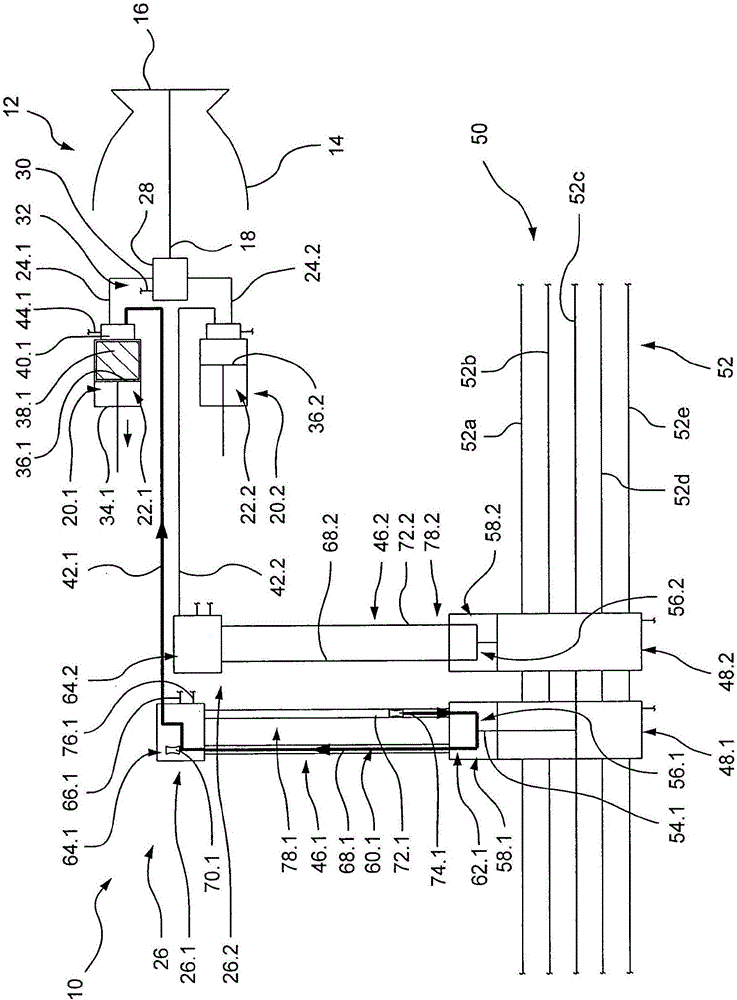

[0033] The drawing schematically shows a painting system 10 for painting objects such as vehicle bodies or parts or components thereof.

[0034] The painting system 10 includes a painting device 12 , which is only shown schematically in the present exemplary embodiment. In the present embodiment, the coating apparatus 12 is an electrostatically operated high speed rotary atomizer 14 having a rotating bell-shaped disk 16 .

[0035] The coating device 12 includes a discharge line 18 via which coating material can be discharged onto objects not specifically shown. In the present embodiment, the output conduit 18 leads to the bell disk 16 of the high speed rotary atomizer 14 . The bell-shaped disk 16 and the outlet duct 18 thus form an outlet device.

[0036] The coating device 12 may optionally be fed material from a first feed container 20.1 in the form of a first piston-type meter 22.1 through a first feed conduit 24.1 of a first supply line 26.1 or from a first feed containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com