Cool regenerated cellulose fiber and its preparation method and textile

A technology of regenerated cellulose and textiles, applied in the field of material processing, can solve the problems of poor sweat absorption, high cost and high price, and achieve the effect of good sweat absorption, low cost and affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

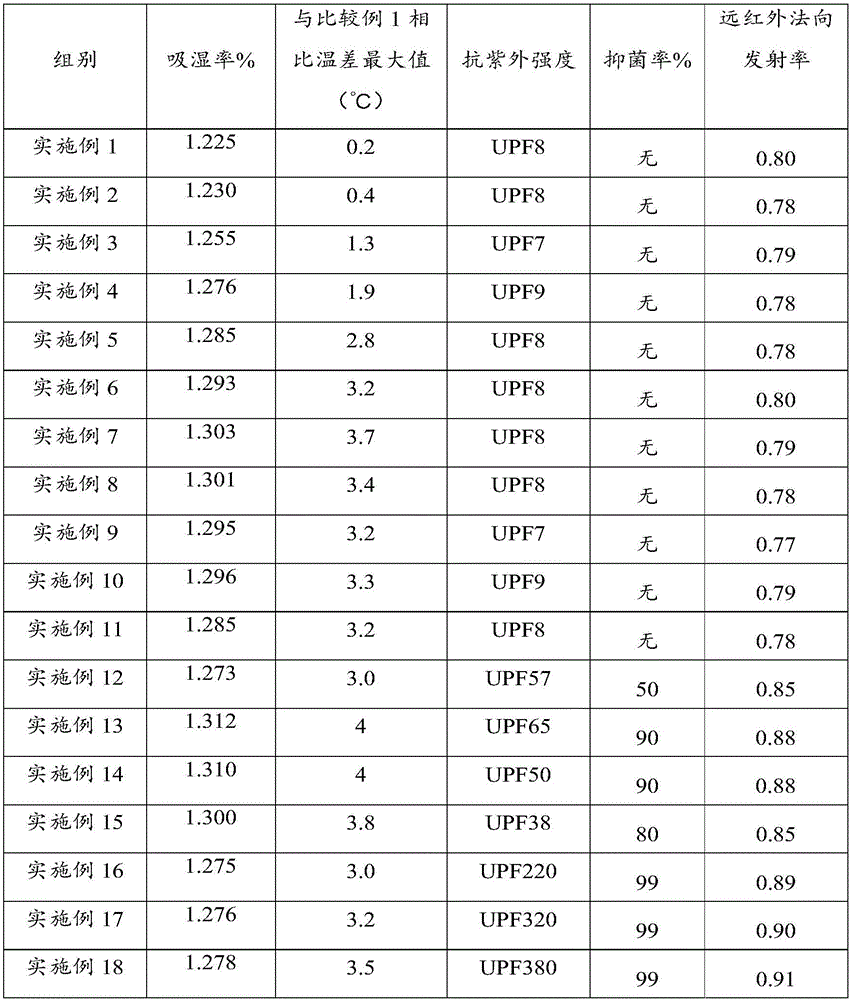

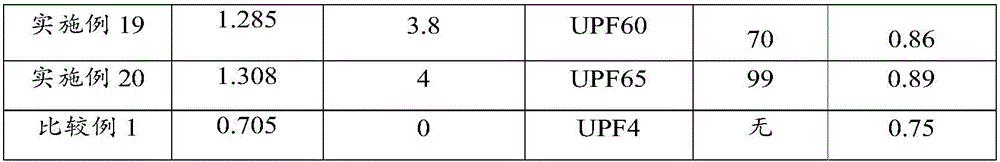

Examples

Embodiment 1

[0045] The preparation method of ice-cold regenerated cellulose fiber is as follows:

[0046] Fully mix 0.001kg of xylitol and 1kg of peanut shell cellulose, the mixing time is 3 hours, and the mixing temperature is 60°C to form a spinning stock solution. When mixing, place the beaker containing the spinning stock solution on an ultrasonic stirrer and mix evenly After standing still for more than 10 minutes, the spinning stock solution is finally filtered, defoamed, and spun to obtain ice-cold regenerated cellulose fibers;

[0047] Among them, the index control of spinning stock solution: methyl fiber content: 9.0%; alkali content: 5%; viscosity: 70s; maturity: 24ml (10% NH4Cl).

[0048] Acid bath forming indicators: sulfuric acid: 130g / L; sodium sulfate: 340g / L; zinc sulfate: 25g / L; temperature: 35°C.

[0049] The specific spinning process is as follows:

[0050] Dipping: temperature 50°C, alkali concentration: 220g / L, denaturant V-388 consumption: 0.5% (for the content of ...

Embodiment 2

[0063] The preparation method of ice-cold regenerated cellulose fiber is as follows:

[0064] First activate and dissolve 1kg of corn cob cellulose to form a spinning stock solution, and dilute 0.01kg of xylitol to a concentration of 10g / L, then add the diluted xylitol to the spinning stock solution and mix thoroughly , the mixing time is 2 hours, and the mixing temperature is 55°C. When mixing, the beaker containing the spinning stock solution needs to be placed on an ultrasonic stirrer, and after mixing evenly, let it stand for more than 20 minutes. Regenerated cellulose fibers, the remaining steps are the same as in Example 1.

Embodiment 3

[0066] Other steps are the same as in Example 2, except that the amount of xylitol added is 0.05kg, and the concentration after dilution is 15g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com