Heat-resistance and salt-tolerance oil well cement filtrate reducer and preparation method and application thereof

A fluid loss reducing agent, oil well cement technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor salt tolerance of the fluid loss reducing agent, and achieve a wide range of applicable temperature and little influence of thickening time. , Good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

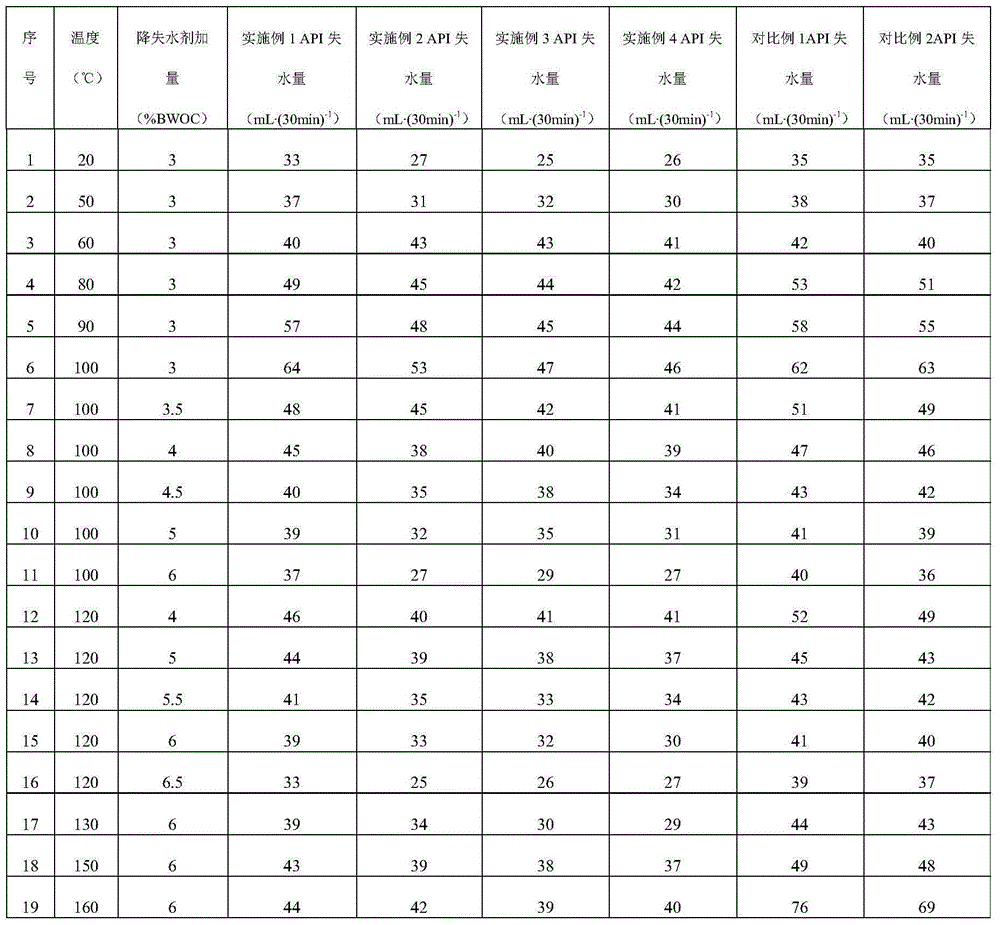

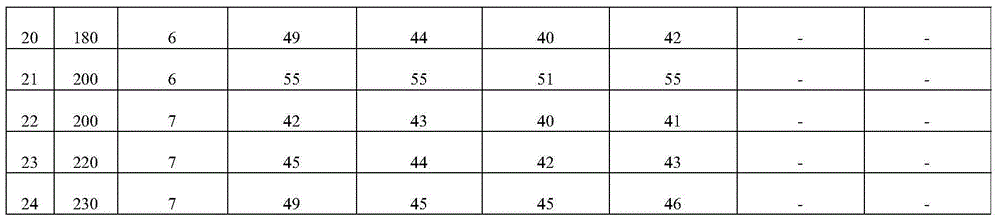

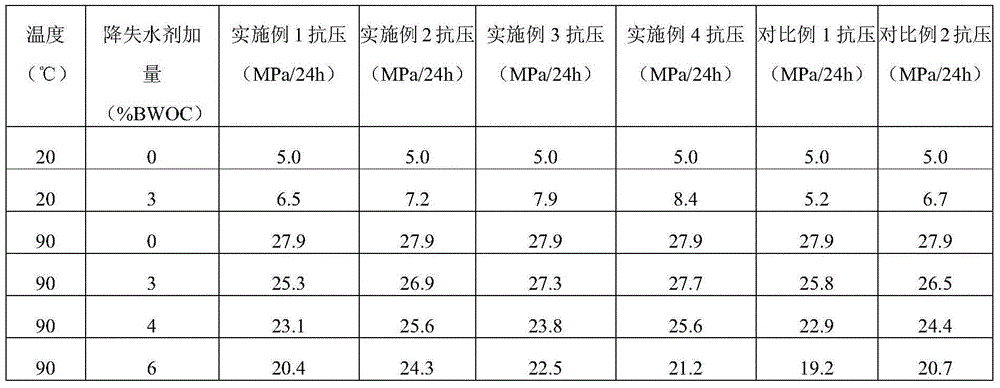

Examples

Embodiment 1

[0043] 100 parts of water, 7 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS); 7 parts of N,N-dimethylacrylamide (DMAA); 4,4'-diaminostilbene- 3 parts of 2,2'-disulfonic acid; 2 parts of 4,4-stilbene dicarboxylic acid; 1 part of methallyl alcohol polyoxyethylene ether (TPEG-2400); stir for 2 minutes. Add 1 part of hydroxide (NaOH), heat to 50°C and keep for 10 minutes; then add 0.1 parts of ammonium persulfate and sodium bisulfite at the same time while stirring, and react for 1 hour under stirring to obtain the present invention Water loss reducer.

Embodiment 2

[0045] 100 parts of water, 8 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS); 8 parts of N,N-dimethylacrylamide (DMAA); 4,4'-diaminostilbene- 4 parts of 2,2'-disulfonic acid; 3 parts of 4,4-stilbene dicarboxylic acid; 2 parts of methallyl alcohol polyoxyethylene ether (TPEG-2400); stir for 10 minutes. Add 2 parts of hydroxide (NaOH), heat to 80°C and keep for 1 hour; then add 0.2 parts of ammonium persulfate and sodium bisulfite while stirring, and react for 5 hours under stirring to obtain the Water loss reducer.

Embodiment 3

[0047] 100 parts of water, 9 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS); 8 parts of N,N-dimethylacrylamide (DMAA); 4,4'-diaminostilbene- 5 parts of 2,2'-disulfonic acid; 4 parts of 4,4-stilbene dicarboxylic acid; 3 parts of methallyl alcohol polyoxyethylene ether (TPEG-2400); stir for 5 minutes. Add 3 parts of hydroxide (NaOH), heat to 60°C and keep for 0.5 hours; then, under stirring, add 0.2 parts of ammonium persulfate and sodium bisulfite at the same time, and react for 3 hours under stirring to obtain the present invention Water loss reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com