Laser cutting head with function of adjusting technological parameters in real-time mode

A technology of laser cutting head and process parameters, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, high device cost, and adding beam switches, so as to achieve no need for lubrication and maintenance, avoid laser damage, The effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

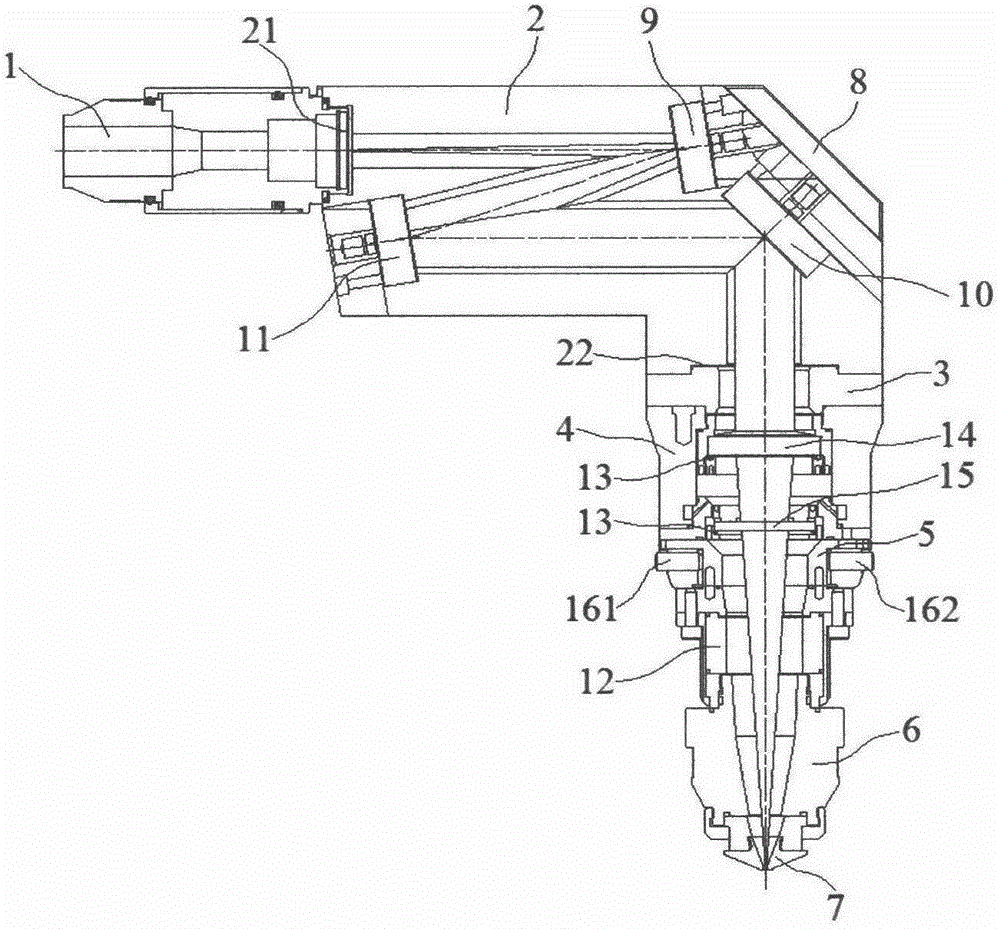

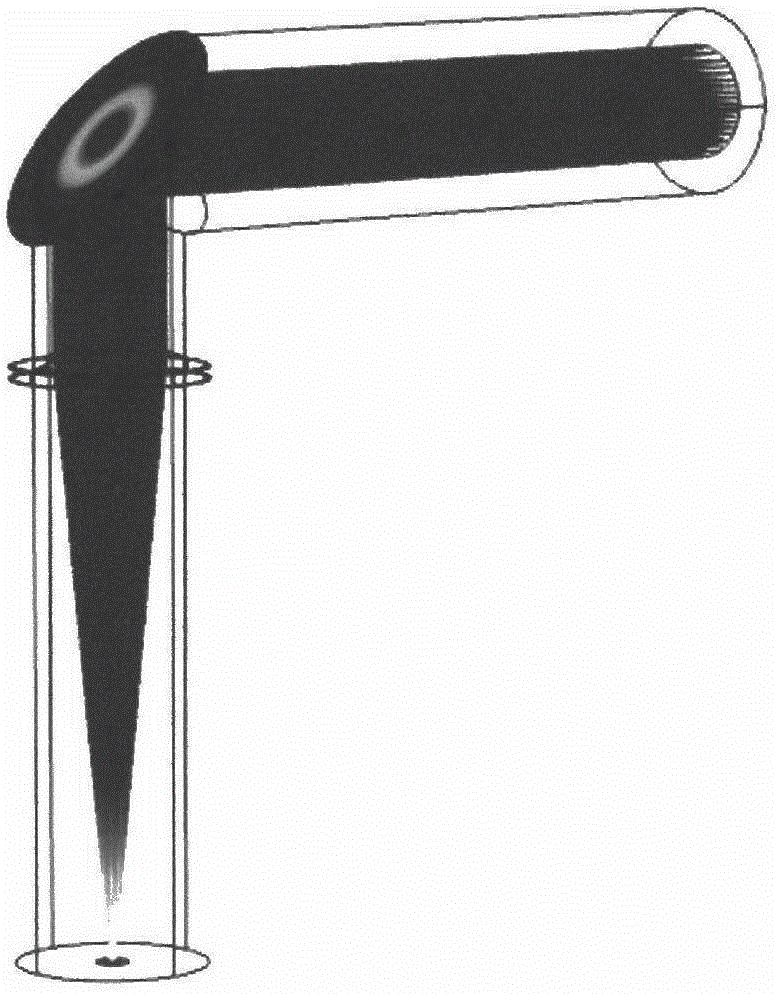

[0044] Embodiment 1: A laser cutting head with the function of adjusting process parameters in real time, including an optical fiber interface 1, a housing 2, an upper positioning ring 3, a connecting sleeve 4, a lower positioning ring 5, a capacitive sensor 6 and a nozzle 7, the housing The front end of the body 2 is provided with a front port 21, the end of the housing 2 is provided with an inclined mounting plate 8, and the lower end of the housing 2 is provided with a lower port 22;

[0045] The optical fiber interface 1 is installed to the front port 21 of the housing 2, and the inclined surface mounting plate 8 located at the end of the inner cavity of the housing 2 is sequentially installed with a variable curvature convex reflector 9 and a variable curvature reflector 10. A variable curvature concave reflector 11 is installed at the front end in the inner cavity of the body 2 and located below the front port 21. The light interface 1, the variable curvature convex refle...

Embodiment 2

[0052] Embodiment 2: A laser cutting head with the function of adjusting process parameters in real time, including an optical fiber interface 1, a housing 2, an upper positioning ring 3, a connecting sleeve 4, a lower positioning ring 5, a capacitive sensor 6 and a nozzle 7, the housing The front end of the body 2 is provided with a front port 21, the end of the housing 2 is provided with an inclined mounting plate 8, and the lower end of the housing 2 is provided with a lower port 22;

[0053] The optical fiber interface 1 is installed to the front port 21 of the housing 2, and the inclined surface mounting plate 8 located at the end of the inner cavity of the housing 2 is sequentially installed with a variable curvature convex reflector 9 and a variable curvature reflector 10. A variable curvature concave reflector 11 is installed at the front end in the inner cavity of the body 2 and located below the front port 21. The light interface 1, the variable curvature convex refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com