Fully-dispersing passive-type multistage focusing micromixer, and mixing method and application thereof

A micro-mixer, passive technology, applied in the field of micro-chemical industry, can solve the problems of high processing precision and processing technology requirements, complex processing of the mixer, poor mixing effect, etc., so as to improve the mixing effect, reduce the pressure drop, and promote the mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

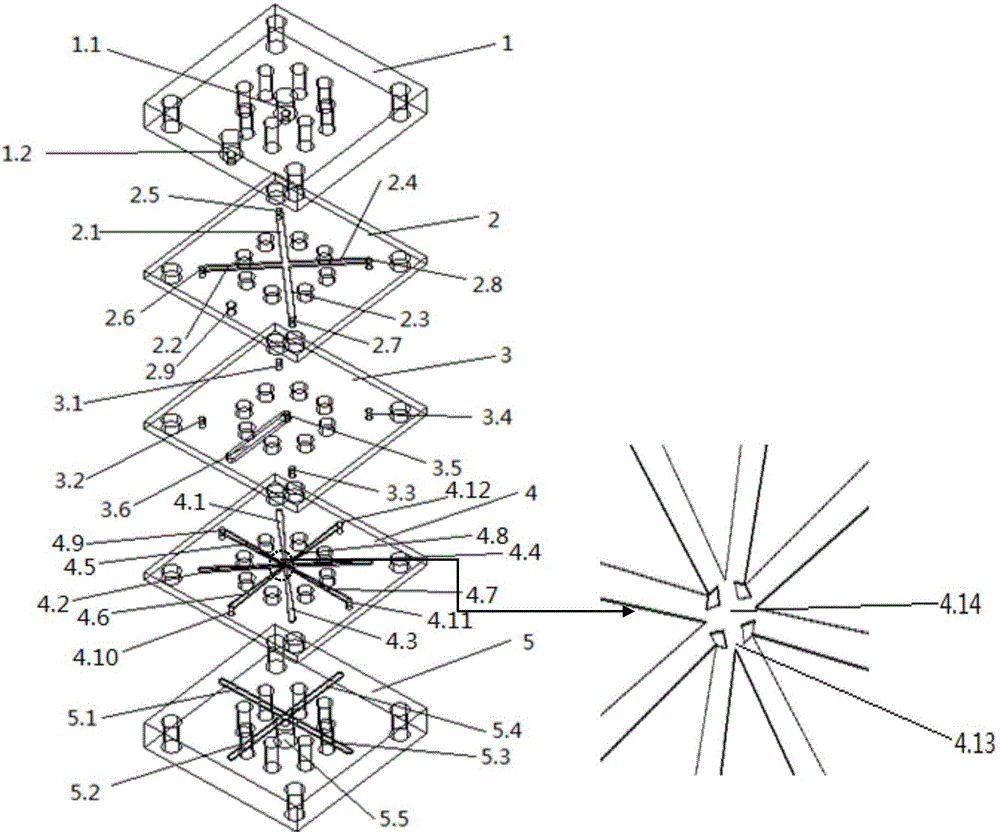

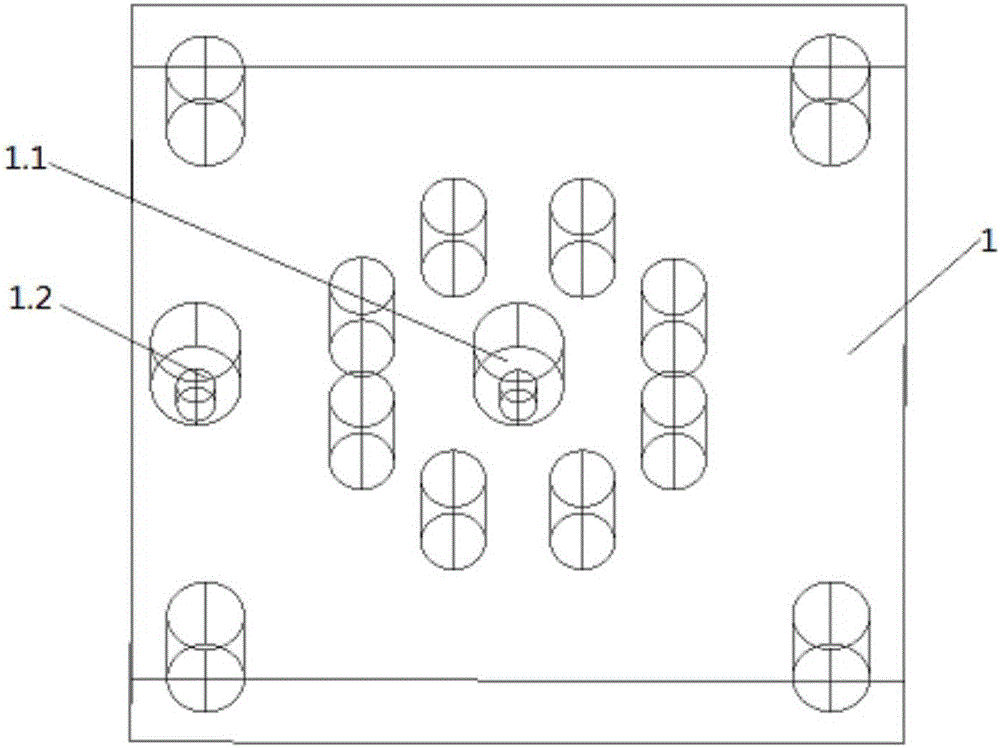

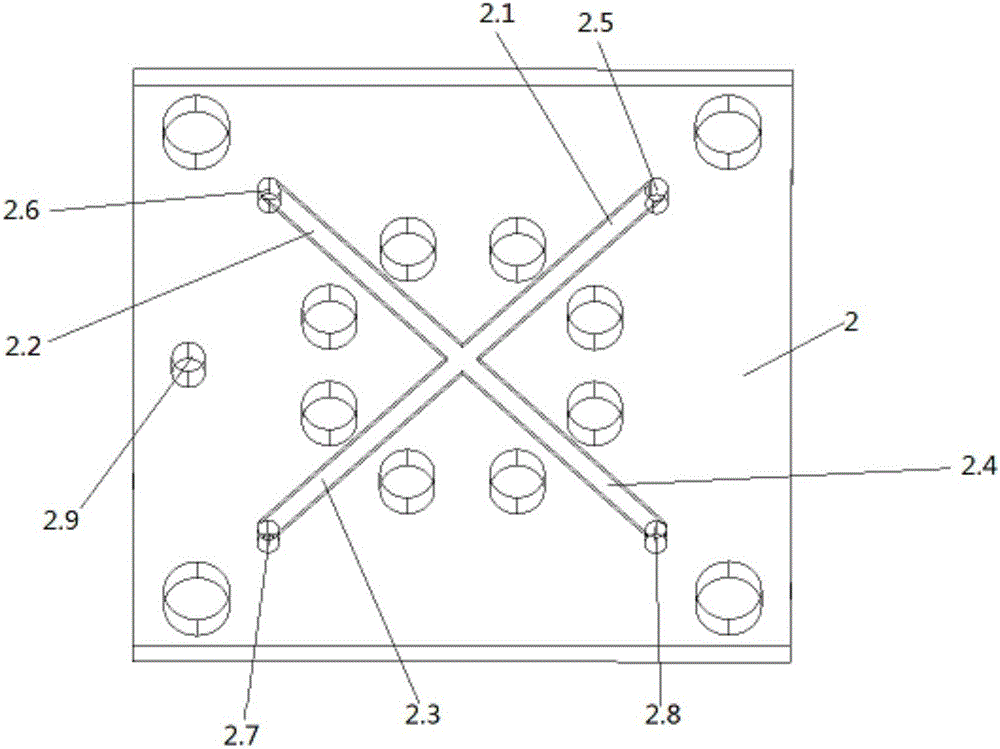

[0046] like Figure 1 to Figure 7 The fully dispersed two-stage focusing micro-mixer shown includes No. 1 plate to No. 5 plate, and the corresponding No. 4 plate is an eight-channel system, and No. 1 plate is provided with a first feed hole 1.1 and a discharge hole 1.2; 2 Channels 2.1 to 2.4 and flow holes 2.5 to 2.8 are opened on the No. plate; flow holes 3.1 to 3.4, outlet flow holes 3.5, and discharge channels 3.6 are opened on the No. 3 plate; scattered channels 4.1 to 4.8 are opened on the No. 4 plate to circulate Holes 4.9 to 4.12; channels 5.1 to 5.4 are opened on the side adjacent to No. 5 plate and No. 4 plate, and the second feeding hole 5.5 is opened on the other side of No. 5 plate; No. 1 plate to No. 5 plates are closely attached to each other The channels 5.1 to 5.4 are aligned with the channels 4.5 to 4.8, the channels 2.1 to 2.4 are aligned with the channels 4.1 to 4.4, the flow holes 2.5 to 2.8 are aligned with the flow holes 3.1 to 3.4, the flow holes 1.2 are...

Embodiment 2

[0051] The difference from Example 1 is that the No. 4 board of the core component adopts a sixteen-channel three-stage focusing method, such as Figure 8 As shown, the number of dispersed channels in the No. 4 plate is 16 channels, and the channel width at the widest part is 1.8 mm, and the channel width at the narrowest part is 0.4 mm. The number of channels from the primary mixing zone to the secondary mixing zone is changed from eight channels to four channels, and the channel width is 0.4mm. The depth of all the channels used in the No. 4 board is 0.5 mm, and the corresponding channels on the No. 2 and No. 5 boards are all eight channels.

Embodiment 3

[0053] The difference from Example 1 is that the No. 4 board of the core component adopts a 32-channel four-stage focusing method, such as Figure 9 As shown, the number of dispersed channels in the No. 4 plate is thirty-two channels, and the corresponding channel width at the widest part is 1.5 mm, and the channel width at the narrowest part is 0.3 mm. The number of channels from the primary mixing zone to the tertiary mixing zone changes from sixteen channels to eight channels and then to four channels, and the channel width is 0.3mm. All channels used in board #4 have a depth of 0.3 mm. The corresponding channels on No. 2 board and No. 5 board are all sixteen channels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com