Liquid crystal display element, liquid crystal composition and liquid crystal alignment film

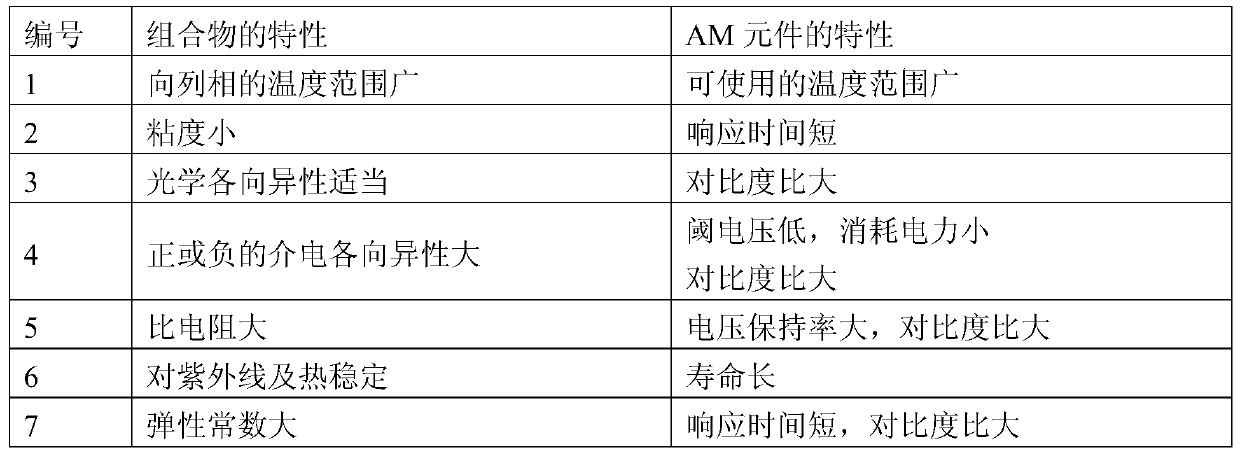

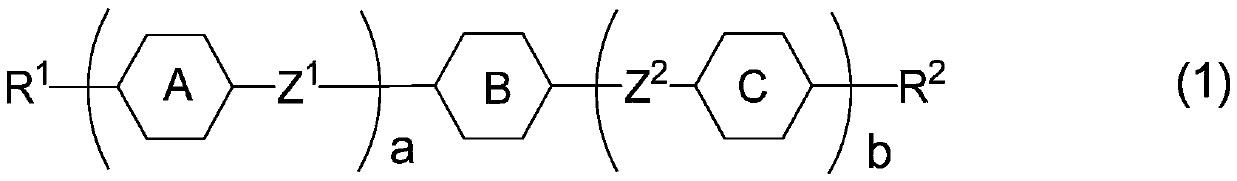

A technology for liquid crystal display elements and liquid crystal alignment films, which is applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of low transmittance and the brightness of liquid crystal display elements, etc., and achieve a large elastic constant and a large voltage retention rate. , the effect of low threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0343] The present invention is further described in detail through examples. The present invention is not limited by these examples. The present invention includes a mixture of the composition of composition example M1 and the composition of composition example M2. The present invention also includes a mixture obtained by mixing at least two of the compositions of the composition examples. The present invention includes a polyamic acid prepared from a mixture of two kinds of tetracarboxylic dianhydrides described in Synthesis Example 2 and Synthesis Example 3. The present invention also includes polyamic acid prepared from a mixture of at least two raw materials (diamine, tetracarboxylic dianhydride or derivatives thereof) described in the synthesis examples. These matters are also the same for Examples such as fabrication of elements. The synthesized compounds were identified by methods such as NMR analysis. The properties of compounds, compositions, and devices were mea...

Synthetic example 1

[0452] Add 1.7806 g of diamine (DI-5-12, m=5) and 18.5 g of dehydrated NMP to a 50 mL brown four-neck flask equipped with a thermometer, a stirrer, a raw material input inlet, and a nitrogen inlet, and stir under a dry nitrogen stream dissolve. Subsequently, 1.2194 g of tetracarboxylic dianhydride (XI-1-1) and 18.5 g of dehydrated NMP were added, and stirring was continued at room temperature for 24 hours. BC 10.0g was added to the said reaction solution, and the polyamic-acid solution whose polymer solid content concentration was 6 weight% was obtained. The polyamic acid solution was referred to as PAA1. The weight average molecular weight of the polyamic acid contained in PAA1 was 38,000.

[0453] [Synthesis Example 2 to Synthesis Example 16]

[0454] Except changing the kind of tetracarboxylic dianhydride and diamine, polyamic acid solution (PAA2) to polyamic acid solution (PAA16) having a polymer solid content concentration of 6% by weight were prepared according to Syn...

Synthetic example 17

[0459] Add 1.4725 g of diamine (DI-5-12, m=5), 18.5 g of dehydrated NMP, and 0.407 g of pyridine as a base into a 50 mL brown four-necked flask equipped with a thermometer, a stirrer, a raw material input port, and a nitrogen gas introduction port. g, stirred and dissolved under dry nitrogen flow. Then add 1.5275 g of dimethyl-1,3-bis(chlorocarbonyl)-1,3-dimethylcyclobutane-2,4-dicarboxylate and 18.5 g of dehydrated NMP, and continue stirring for 6 hours under water cooling . Pyridine was removed by distillation, NMP10.0g was added to the reaction solution, and the polyamic acid ester solution whose polymer solid content density|concentration was 6 weight% was obtained. Let the said polyamic acid ester solution be PAE1. The weight average molecular weight of the polyamic acid ester contained in PAE1 is 11,000.

[0460] [Synthesis Example 18 to Synthesis Example 27]

[0461] In addition to changing the types of tetracarboxylic acid diester dichloride and diamine, according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com