Pneumatic Impulse Tools with Shutoff Mechanism

A pulse and tool technology, applied in the direction of motor tools, manufacturing tools, portable motor devices, etc., can solve the problems of simple production and implementation, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

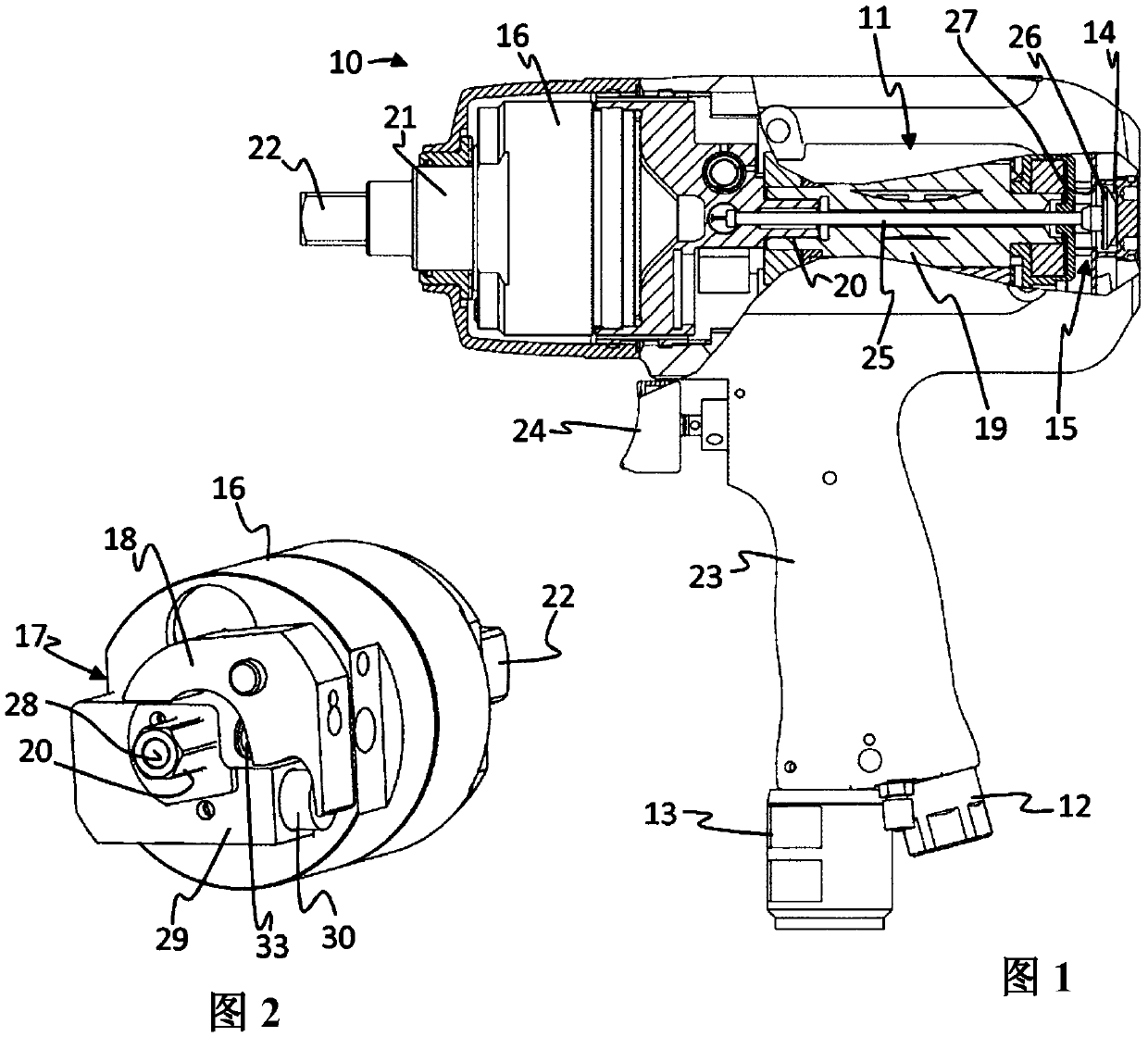

[0022] exist figure 1 A pneumatic torque pulse transmission power tool 10 with an automatic power shutoff mechanism is shown in . The power tool 10 includes an air motor 11 driven by pressurized air. An air inlet portion 12 is arranged to be connected to a supply of pressurized air and an air outlet portion 13 is arranged to discharge air from the motor. An air supply passage 14 is provided for supplying pressurized air to the motor 11 , and the air supply passage 14 includes a shut-off valve 15 .

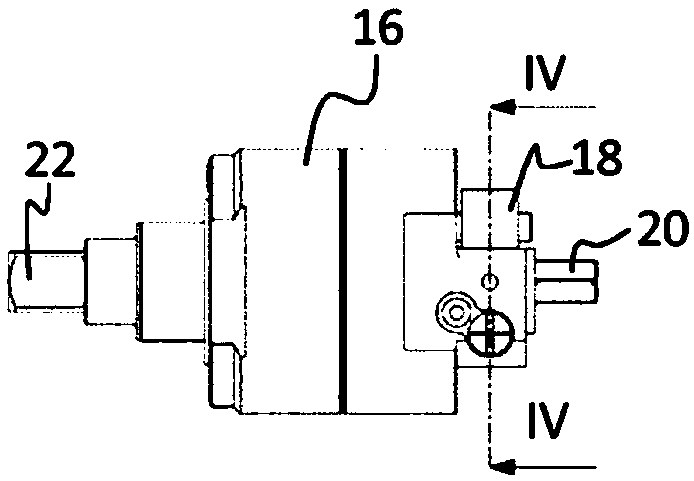

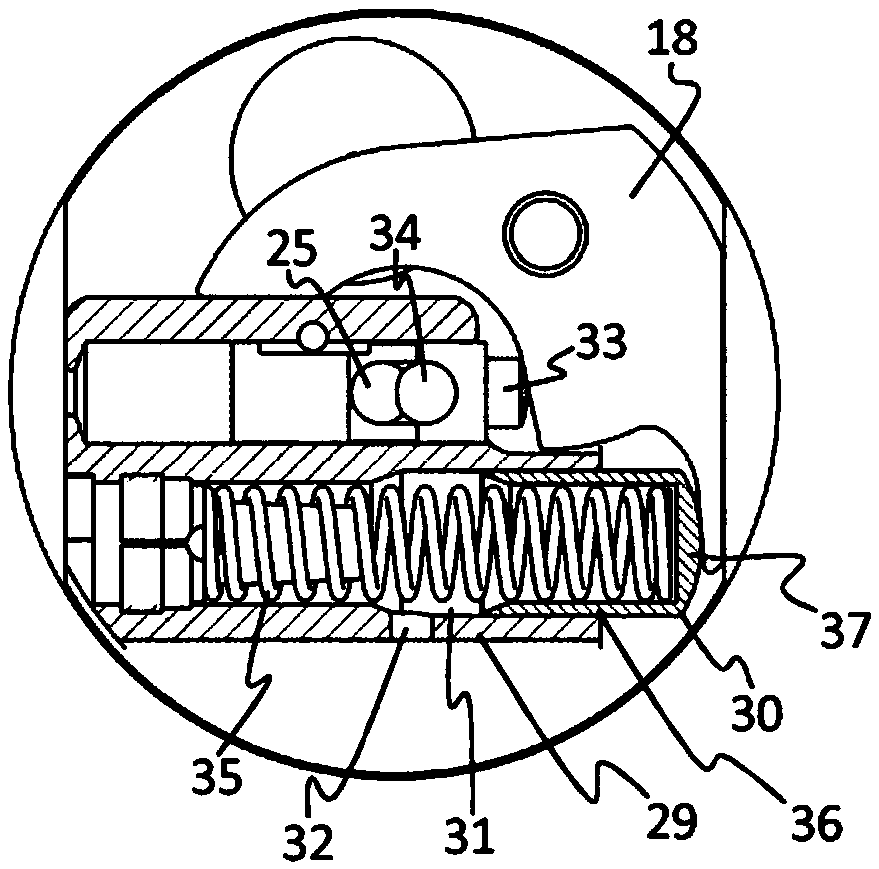

[0023] Furthermore, the power tool 10 includes a drive member 16 driven in rotation by means of the air motor 11 . The drive member is connected to the rotor 19 of the motor 11 via a hexagonal connection 20 . The drive member 16 intermittently drives an anvil 21 partially located in the drive member 16 and extending through the front of the drive member and integrally connected to an output shaft 22 . Additionally, the illustrated power tool 10 includes a handle 23 and a trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com