Optimized method for setting expansion anchors by means of a power tool

A technology of a machine tool and an expansion sleeve is applied in the field of optimized installation of an expansion anchor by means of a machine tool, and can solve problems such as limiting the application range of the expansion anchor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

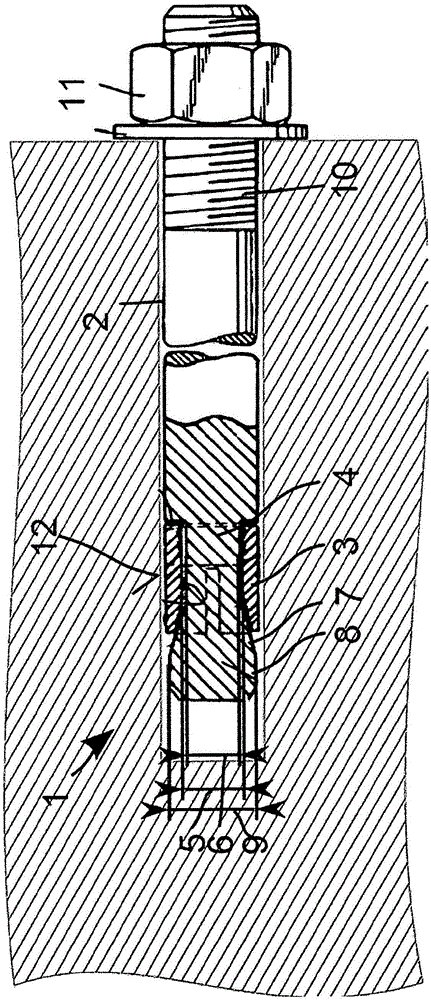

[0027] figure 1 An exemplary expansion anchor 1 comprising a tie rod 2 and an expansion sleeve 3 is shown. The expansion sleeve 3 surrounds the cylindrical section 4 of the tie rod 2 in the circumferential direction. The outer diameter 5 of the cylindrical section 4 is preferably slightly smaller than the inner diameter 6 of the expansion sleeve 3 , so that the tie rod 2 is axially movable relative to the expansion element 3 . The cylindrical section 4 merges into a conical section 7 which forms the expansion body 8 for expanding the expansion sleeve 3 . The largest diameter of the conical section 7 is larger than the inner diameter 6 of the expansion sleeve 3 and preferably smaller than the outer diameter 9 of the expansion sleeve 3 . A thread 10 is provided on the tie rod 2 , by means of which a traction force can be introduced. In the exemplary expansion anchor 1 , the thread 10 is simultaneously used for load-bearing fastening. During assembly, the expansion anchor 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com