Resistance spot welding device and resistance spot welding method

A technology of resistance spot welding and welding materials, which is applied in resistance welding equipment, welding/welding/cutting items, welding equipment, etc., and can solve the problems of complex composition of welding control devices, expensive welding control devices, complex calculation and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Examples of the present invention are shown below.

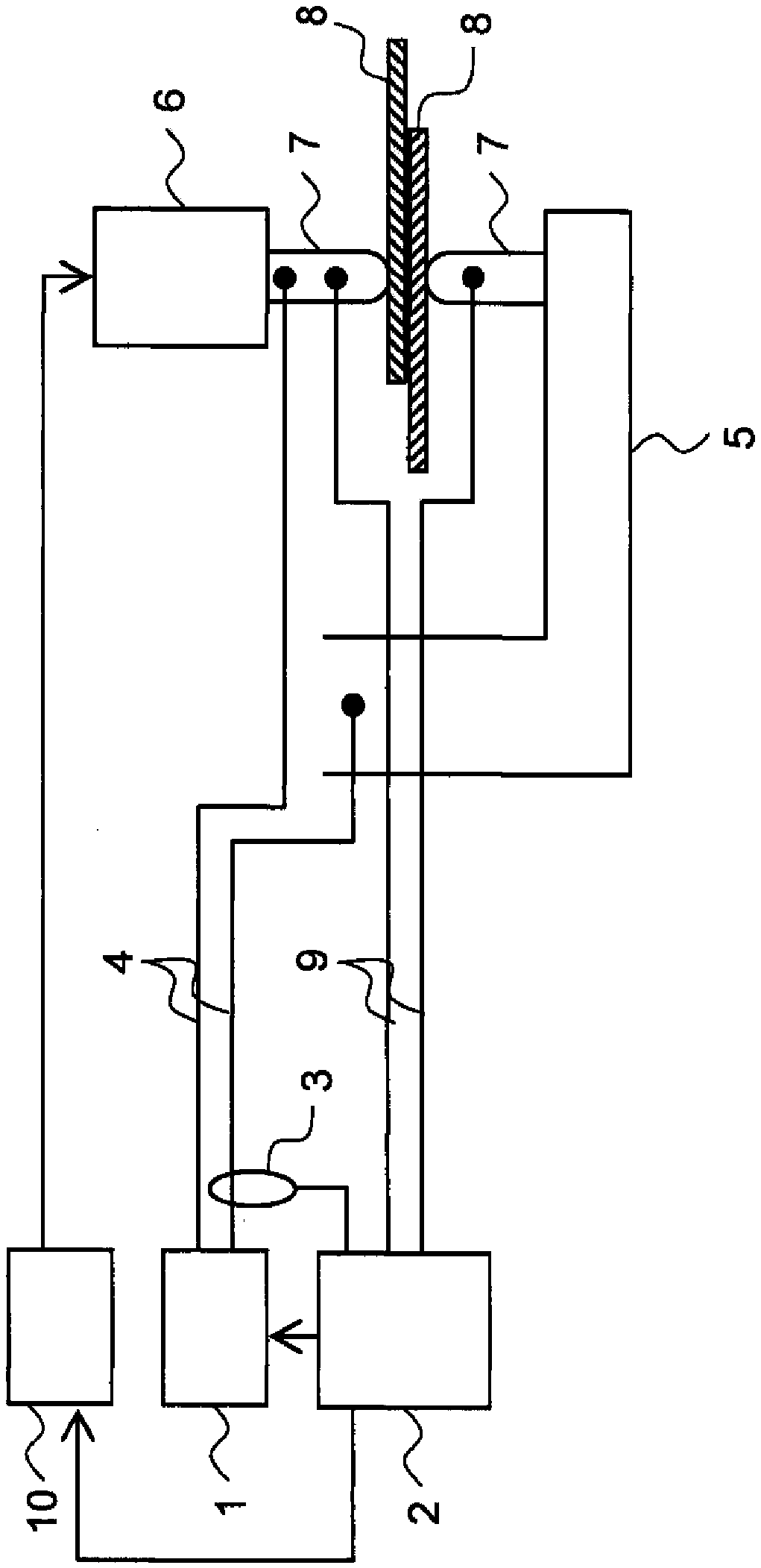

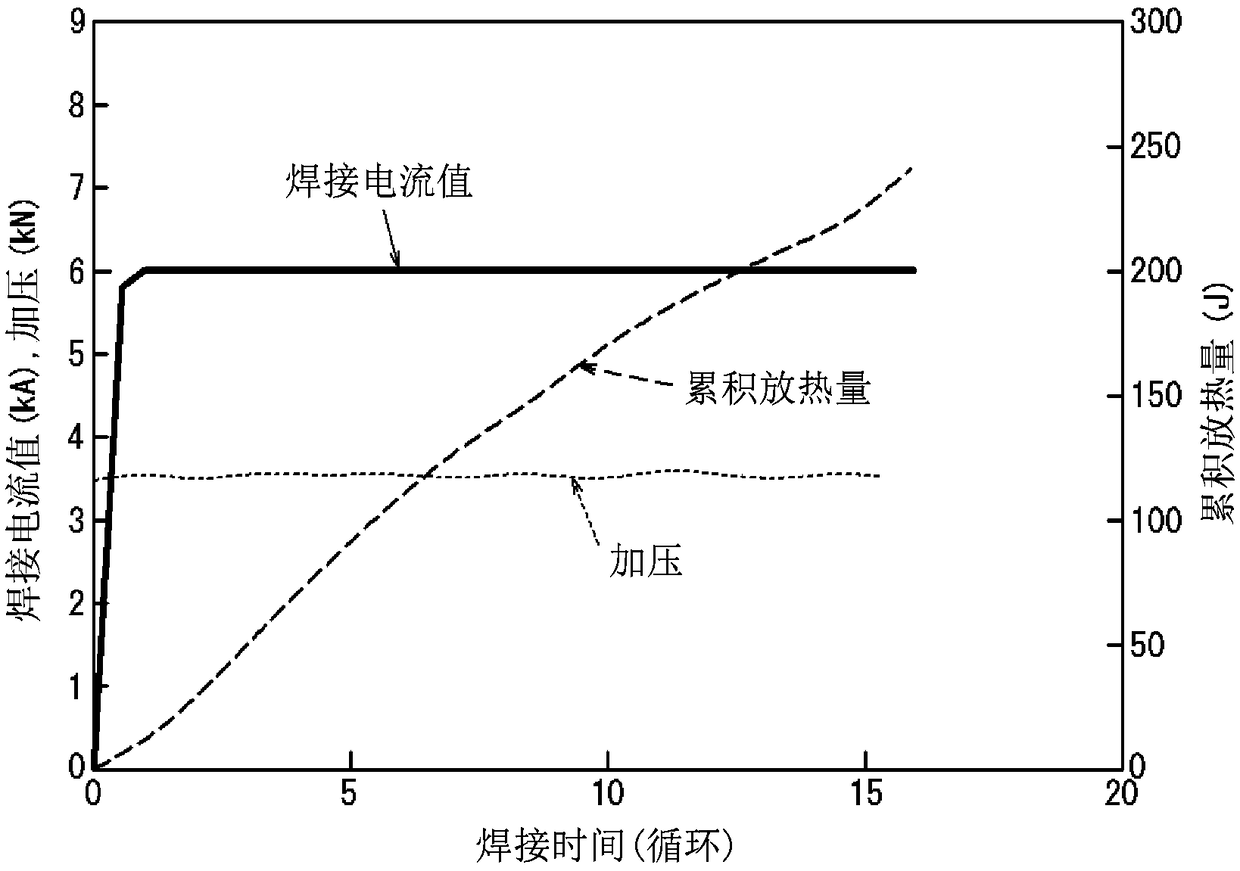

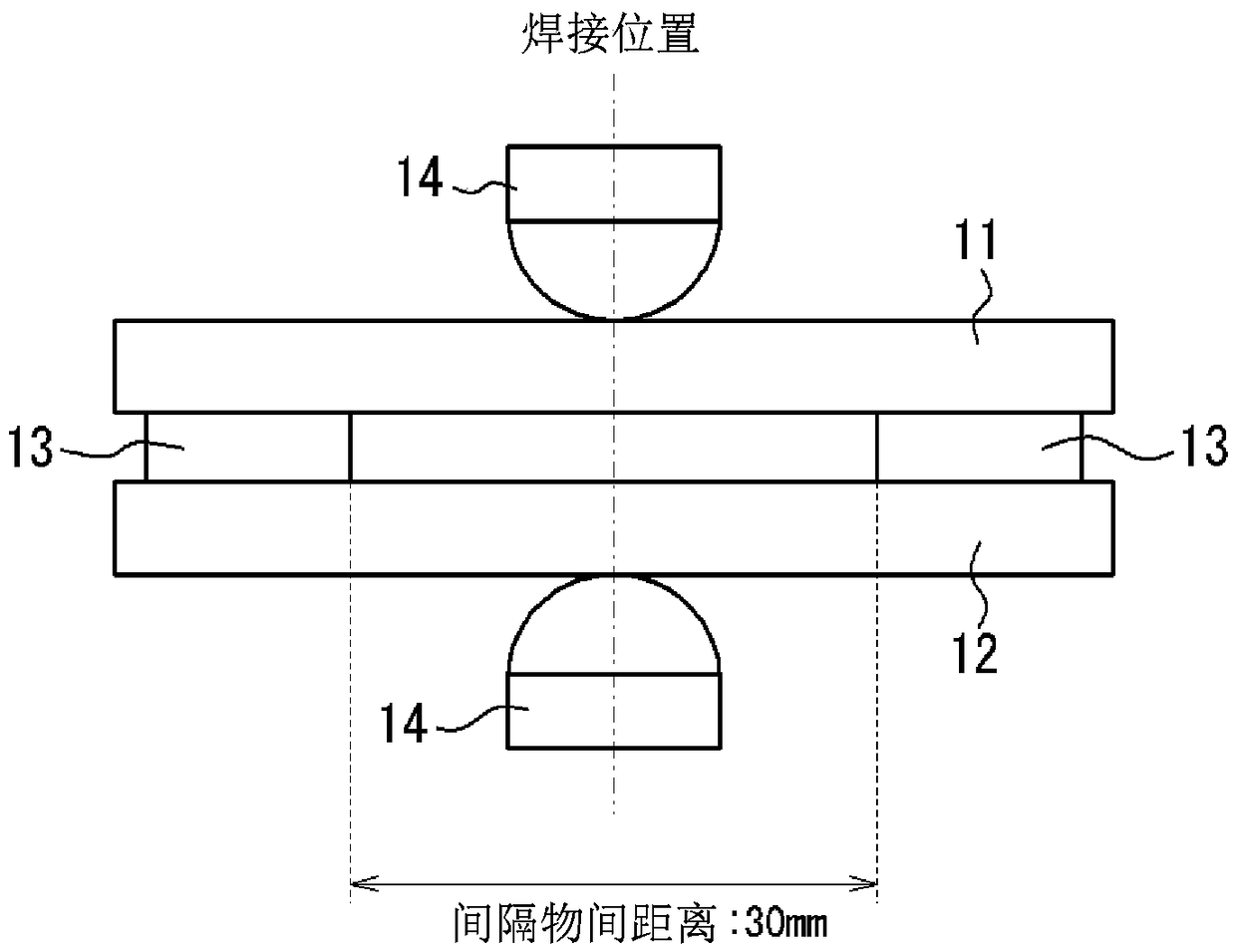

[0091] As the material to be welded, cold-rolled steel sheets (thickness: 1.6 mm) of 590 MPa class and 980 MPa class were used. Two sheets of this material to be welded were laminated, and preliminary welding was performed by constant current control in a state where there was no gap or diversion to the existing welding point, and the welding conditions for obtaining an appropriate nugget diameter were obtained. The welding machine uses an inverter DC resistance spot welder, and the electrode uses a chrome-copper electrode with a DR-shaped front-end diameter of 6mm. In addition, the welding conditions are as follows: pressurization: 3.5kN, welding current: 6.0kA, energization time: 16 cycles (50Hz (hereinafter, the unit of time is the number of cycles at 50Hz)). And, use figure 1 The resistance spot welding apparatus shown performs test welding under the above-mentioned welding conditions, and stores the temporal ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com