MEMS microphone encapsulation

A microphone and ASIC chip technology, applied in the field of acoustic and electrical products, can solve the problems of high electrical signal transmission consumption, poor product reliability, electrical signal distortion, etc., and achieve the effects of low transmission consumption, low production cost, and improved performance and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

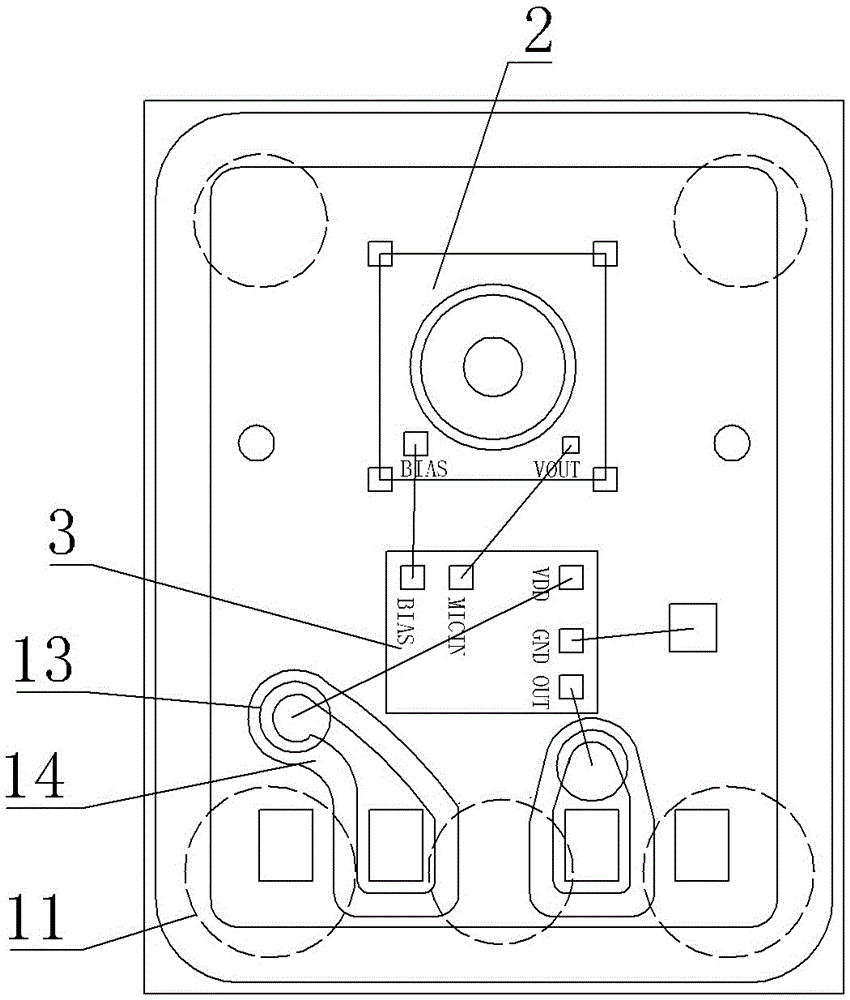

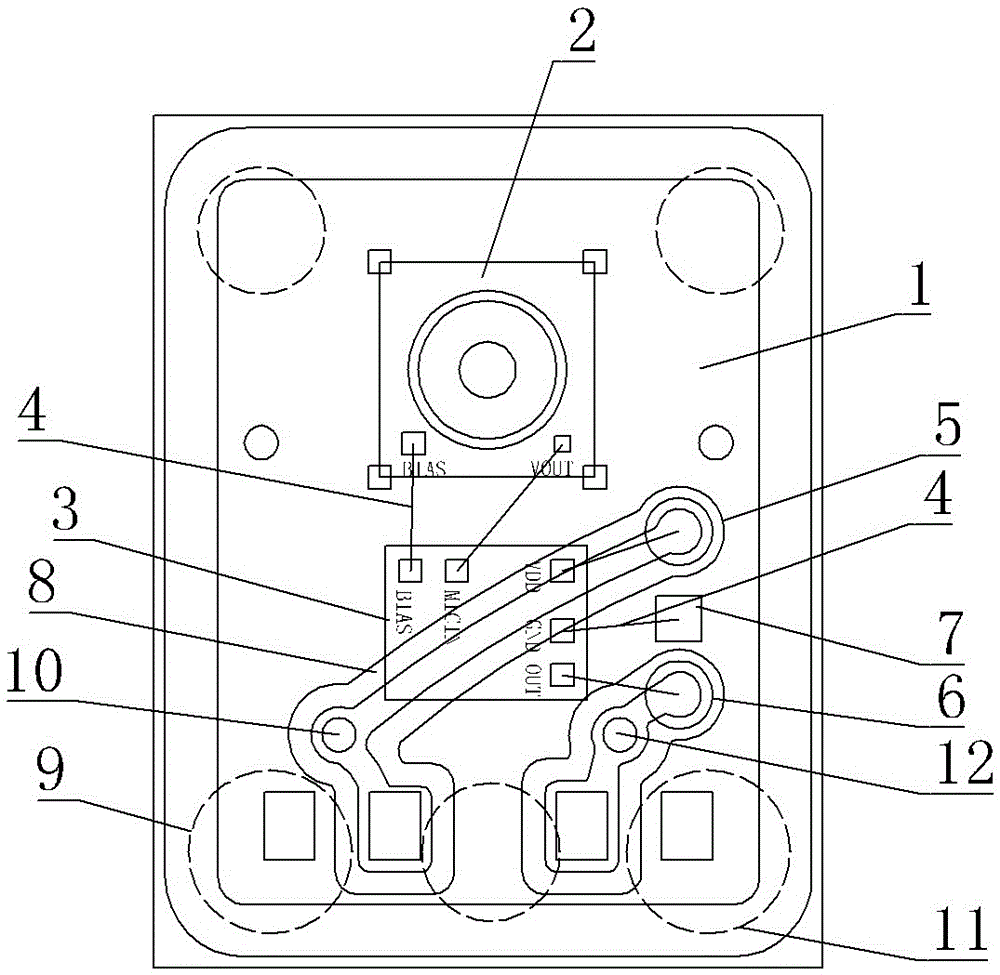

[0014] See figure 2 , a MEMS microphone package, including an upper PCB board 1 and a lower PCB board, the upper PCB board 1 is provided with a MEMS chip 2 and an ASIC chip 3, the ASIC chip is NJU72082G, the MEMS chip is NJD3005e, and the BIAS of the MEMS chip 2 The port is connected to the BIAS port of the ASIC chip 3 through a gold wire 4, the VOUT port of the MEMS chip 2 is connected to the MICIN port of the ASIC chip 3 through a gold wire, and the VDD port of the ASIC chip 3 is connected to the VDD soldering port on the front side of the upper PCB board 1 through a gold wire. Disk 5, the OUT port of the ASIC chip 3 is connected to the output pad 6 arranged on the front of the upper PCB board 1 through a gold wire, and the GND port of the ASIC chip 3 is connected to the ground pad 7 arranged on the front of the upper PCB board 1 through a gold wire. The first copper layer 8 and the second copper layer 9 are arranged between the PCB 1 and the lower PCB, and the VDD pad 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com