CMS/MnO2/PPY (carbon microsphere/manganese dioxide/polypyrrole) composite electrode material, as well as preparation method and application thereof

A composite electrode and mixed solution technology is applied in the field of composite materials to achieve the effects of easy commercialization and large-scale production, uniform PPY dispersion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (A)CMS / MnO 2 Preparation of / PPY composite electrode material

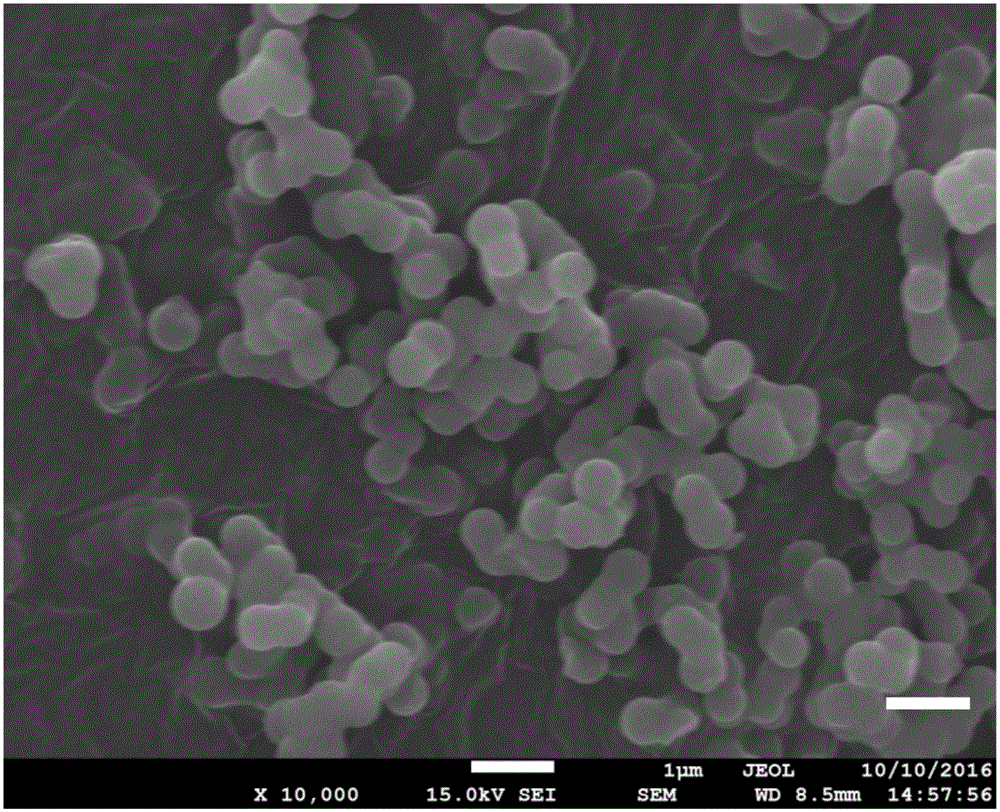

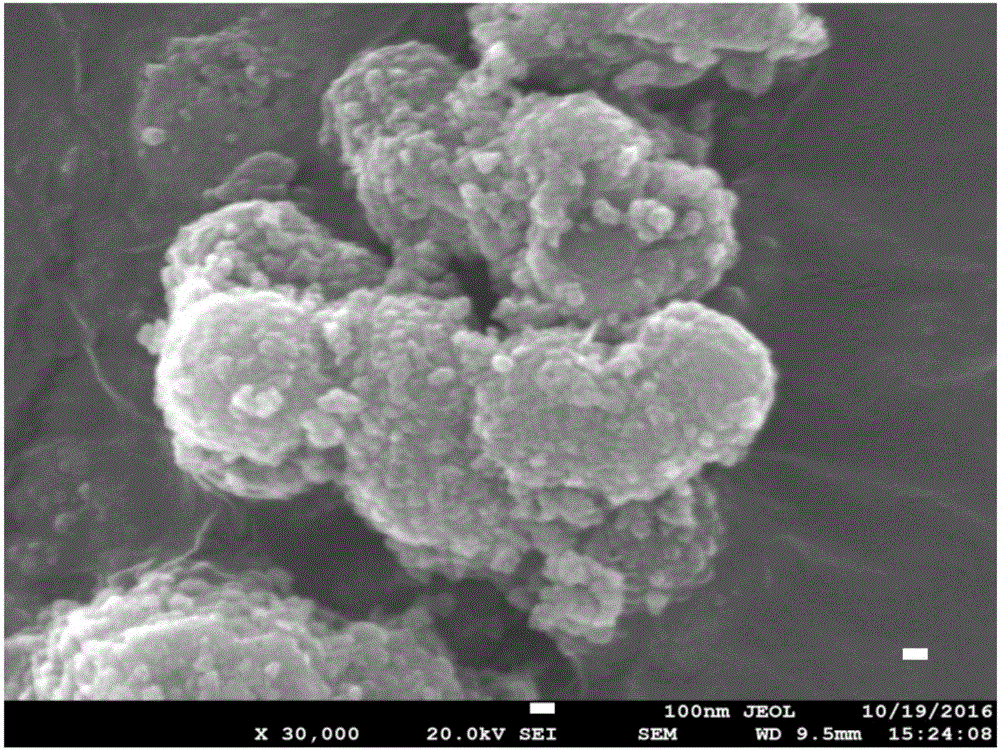

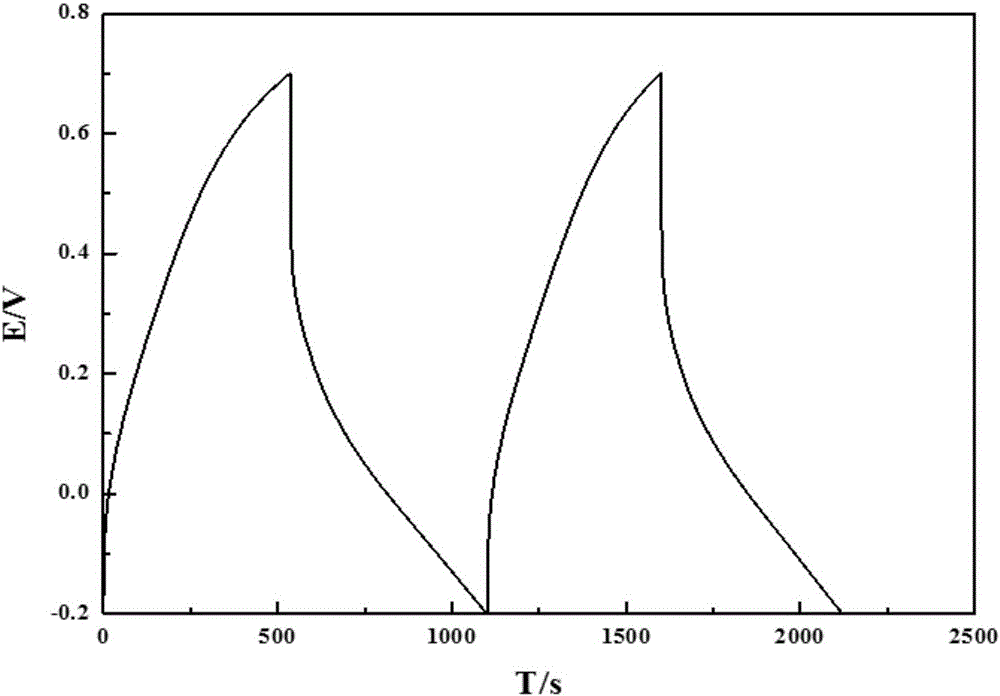

[0047] Put 4g of glucose and 40mL of distilled water into a 50mL stainless steel reactor with built-in polytetrafluoroethylene, react at 180°C for 12h, then cool, centrifuge, wash thoroughly, and then dry at 60°C for 6h to obtain the carbon microsphere material; Add 0.05g of the carbon microsphere material prepared above, add 10mL of distilled water, and sonicate for 10min; weigh 0.25g of potassium permanganate, add it to the above mixed solution, stir to make it fully dissolve; then place it in an ultrasonic cleaning machine with an ultrasonic power of 400W Sonicate in the device for 30 minutes, and control the temperature at 10-35°C; centrifuge the black suspension after ultrasonication, wash thoroughly, and dry at 80°C for 6 hours to obtain CMS / MnO 2 Material. Add 0.4g of p-toluenesulfonic acid into 30mL of absolute ethanol and stir evenly, then add 0.05g of pyrrole into the above solution, stir for 10...

Embodiment 2

[0061] Put 4g of glucose and 40mL of distilled water into a 50mL stainless steel reactor with built-in polytetrafluoroethylene, react at 180°C for 12h, then cool, centrifuge, wash thoroughly, and then dry at 60°C for 6h to obtain the carbon microsphere material; Add 0.05g of the carbon microsphere material prepared above, add 10mL of distilled water, and sonicate for 10min; weigh 0.25g of potassium permanganate, add it to the above mixed solution, stir to make it fully dissolve; then place it in an ultrasonic cleaning machine with an ultrasonic power of 400W Sonicate in the device for 60 minutes, and control the temperature at 10-35°C; centrifuge the black suspension after ultrasonication, wash thoroughly, and dry at 80°C for 6 hours to obtain CMS / MnO 2 Material. Add 0.3g of p-toluenesulfonic acid into 30mL of absolute ethanol and stir evenly, then add 0.03g of pyrrole into the above solution, stir for 10min, and record it as solution A; add 0.04g of ammonium persulfate into 2...

Embodiment 3

[0063] Put 4g of glucose and 40mL of distilled water into a 50mL stainless steel reactor with built-in polytetrafluoroethylene, react at 180°C for 15h, then cool, centrifuge, wash thoroughly, and then dry at 60°C for 6h to obtain the carbon microsphere material; Add 0.01g of the carbon microsphere material prepared above, add 10mL of distilled water, and ultrasonicate for 10min; weigh 0.1g of potassium permanganate, add it to the above mixed solution, stir to make it fully dissolve; then place it in an ultrasonic cleaning machine with an ultrasonic power of 400W Sonicate in the device for 30 minutes, and control the temperature at 10-35°C; centrifuge the black suspension after ultrasonication, wash thoroughly, and dry at 80°C for 6 hours to obtain CMS / MnO 2 Material. Add 0.4g of p-toluenesulfonic acid into 30mL of absolute ethanol and stir evenly, then add 0.05g of pyrrole into the above solution, stir for 10min, and record it as solution A; add 0.04g of ammonium persulfate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com