Infrared dye cascade sensitized dye-sensitized solar cell photoanode and preparation method thereof

A technology of solar cells and infrared dyes, which is applied in the field of preparation of photoanode materials for solar cells, can solve the problems of weakly absorbing sunlight in the infrared band, achieve high-efficiency wavelength conversion characteristics, enhance photoelectric conversion efficiency, and effectively and comprehensively utilize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

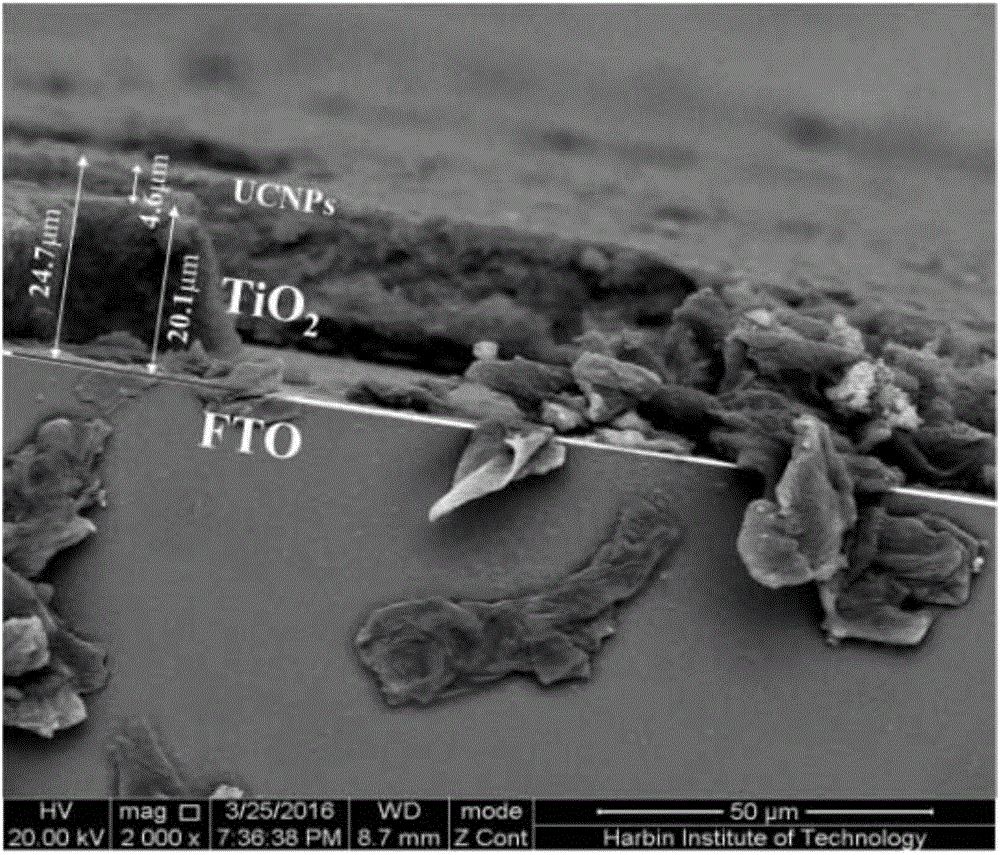

[0029] Embodiment 1: The dye-sensitized solar cell photoanode of the infrared dye cascade sensitization of this embodiment is composed of an FTO conductive glass substrate, a titanium dioxide layer loaded with N719 dye, and an IR783 infrared dye-sensitized NaYF 4 :Yb / Er@NaYF 4 : Nd layer composition; the titanium dioxide layer loaded with N719 dye is the middle layer, and the IR783 infrared dye-sensitized NaYF 4 :Yb / Er@NaYF 4 : The Nd layer is the surface layer.

specific Embodiment approach 2

[0030] Specific embodiment two: the preparation method of the dye-sensitized solar cell photoanode described in the specific embodiment one of the infrared dye cascade sensitization is carried out according to the following steps:

[0031] Step 1: After cutting the FTO conductive glass according to the size of the photoanode, drill the electrolyte injection hole, clean it and dry it to obtain the substrate;

[0032] Step 2: Weigh ethyl cellulose, titanium dioxide powder, terpineol and ethanol, first dissolve ethyl cellulose in ethanol by ultrasonic, then add titanium dioxide powder and terpineol, stir ultrasonically for 1h to 3h, heat to remove ethanol, and obtain slurry;

[0033] Step 3: Scrape-coat the slurry prepared in step 2 on the FTO conductive glass substrate treated in step 1, dry it at room temperature, put it in a muffle furnace, and heat it up for sintering to obtain a titanium dioxide-loaded FTO conductive glass substrate;

[0034] Step 4: According to the concen...

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is different from Embodiment 2 in that the diameter of the electrolyte injection hole in step 1 is 0.8mm-1mm. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com