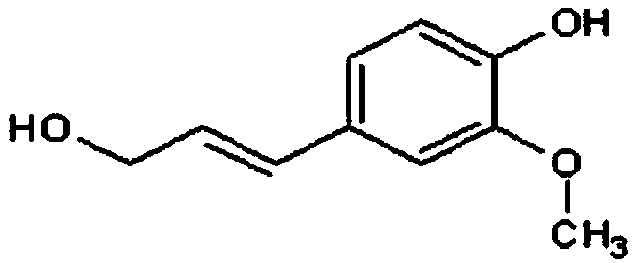

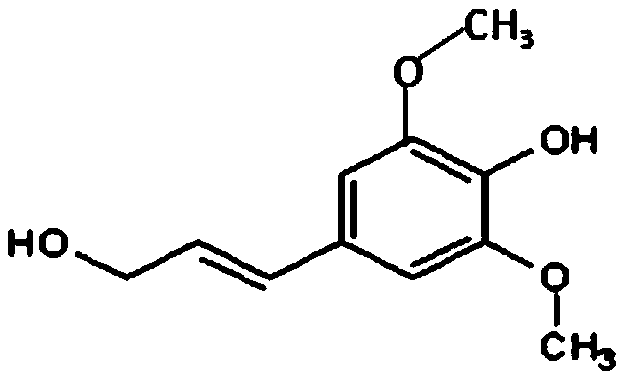

A method for the separation and detection of coniferyl alcohol and sinapyl alcohol by gas chromatography

A gas chromatography-mass spectrometry and coniferyl alcohol technology, which is applied in material separation, measuring device, analyzing materials, etc., can solve the problems of less research on coniferyl alcohol and sinapyl alcohol, no separation and detection methods, etc., and achieves easy implementation, good application prospect, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

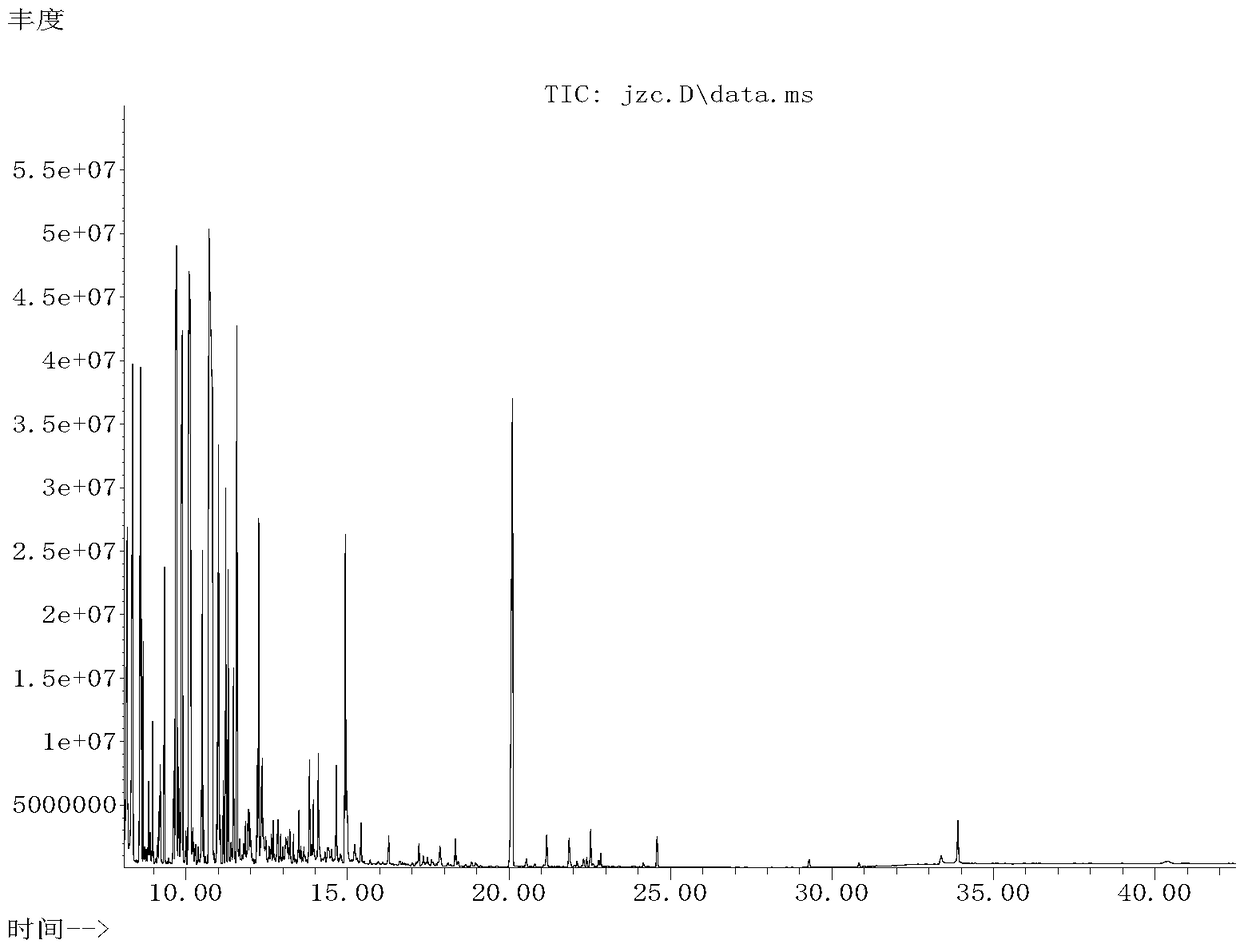

Image

Examples

Embodiment 1

[0028] A method for separating and detecting coniferyl alcohol and sinapyl alcohol by gas chromatography, comprising the following steps:

[0029] (1) Preparation of the test product

[0030] (a) Accurately weigh 0.0010 mg coniferyl alcohol and 0.0010 mg sinapyl alcohol using an analytical balance;

[0031] (b) The weighed coniferyl alcohol and sinapyl alcohol were dissolved in 2mL chromatographic grade pyridine respectively to obtain a coniferyl alcohol standard solution and a sinapyl alcohol standard solution;

[0032] (c) Take 100 μL coniferyl alcohol standard solution and 100 μL sinapyl alcohol standard solution respectively, and then carry out derivatization treatment respectively. The specific process of derivatization treatment is: add 60 μL hydroxylamine hydrochloride pyridine solution (20mg hydroxylamine hydrochloride / mL pyridine, the same below ), vortexed for 60s, then oximated at 100°C for 2h, then added 60μL of BSTFA+TMCS (99:1) silylating reagent, vortexed for 6...

Embodiment 2

[0041] A method for separating and detecting coniferyl alcohol and sinapyl alcohol by gas chromatography, comprising the following steps:

[0042] (1) Preparation of the test product

[0043] (a) Accurately weigh 0.0010 mg coniferyl alcohol and 0.0010 mg sinapyl alcohol using an analytical balance;

[0044] (b) Dissolve the weighed coniferyl alcohol and sinapyl alcohol in 4mL chromatographic grade pyridine to obtain a mixed standard solution;

[0045] (c) Take 100 μL of mixed standard solution, and then perform derivatization treatment. The specific process of derivatization treatment is: add 50 μL of hydroxylamine pyridine hydrochloride solution, vortex for 30 seconds, and then oximate at 100°C for 1.5 hours, then add 50 μL BSTFA+TMCS (99:1) silanization reagent, vortex for 30s, and finally silanization at 100°C for 1.5h to obtain a mixed sample to be tested;

[0046] (2) Separation and detection of the test product

[0047] Use gas chromatography-mass spectrometry to sepa...

Embodiment 3

[0054] A method for separating and detecting coniferyl alcohol and sinapyl alcohol by gas chromatography, comprising the following steps:

[0055] (1) Preparation of the test product

[0056] (a) Accurately weigh 0.0010 mg coniferyl alcohol and 0.0010 mg sinapyl alcohol using an analytical balance;

[0057] (b) Dissolve the weighed coniferyl alcohol and sinapyl alcohol in 4mL chromatographic grade pyridine to obtain a mixed standard solution;

[0058] (c) Take 100 μL of the mixed standard solution, and then perform derivatization treatment. The specific process of derivatization treatment is: add 70 μL of hydroxylamine pyridine hydrochloride solution, vortex for 45 seconds, and then oximate at 100°C for 2.5 hours, then add 70 μL BSTFA+TMCS (99:1) silanization reagent, vortex for 45s, and finally silanization at 100°C for 2.5h to obtain a mixed sample to be tested;

[0059] (2) Separation and detection of the test product

[0060] Use gas chromatography-mass spectrometry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com