Horizontal high-precision detector for comprehensive performances of precision speed reduction device

A precision reducer, comprehensive performance technology, applied in the testing of machine/structural components, machine gear/transmission mechanism testing, instruments, etc., can solve the problems of insufficient structural rigidity of testing equipment, easy transmission of deformation errors, superposition and even amplification, etc. Achieve the effect of solving the influence of mechanical deformation on the measurement accuracy, reducing the deformation of the casing and reducing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

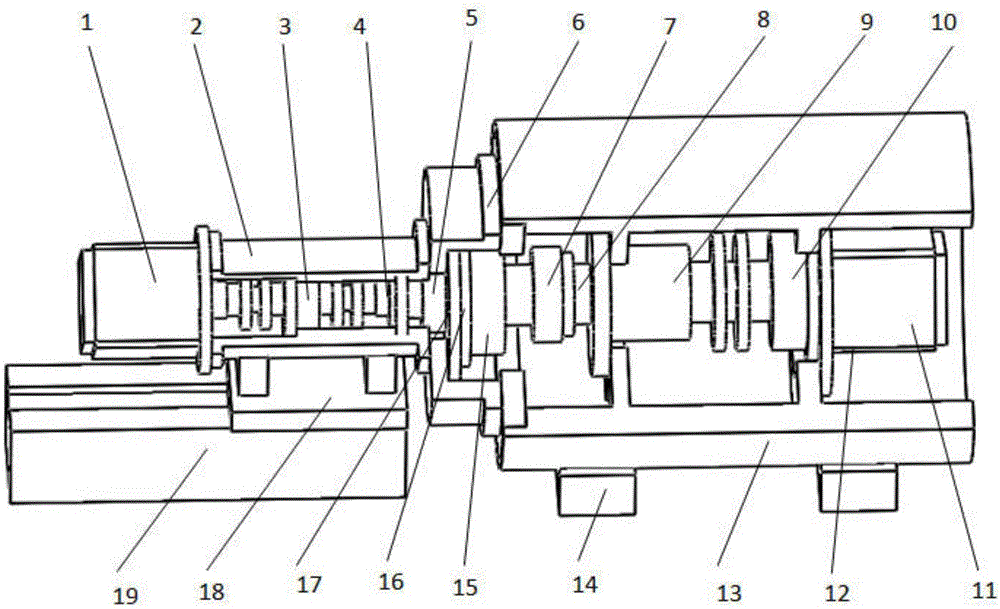

[0014] see figure 1 , a horizontal high-precision detector for comprehensive performance of precision reducers, including a high-speed end torque closure module, a position adjustment module and a low-speed end torque closure module.

[0015] The low-speed end moment closing module includes a horizontally arranged low-speed end moment closing cylinder 13, and a support leg 14 is provided at the bottom of the low-speed end moment closing cylinder 13, and the low-speed end moment closing cylinder 13 is sequentially arranged from right to left. A loading motor 11, a booster reducer 10, a low-speed end torque sensor 9, a low-speed end circular grating 8 and a reducer output shaft adapter 7 are provided. The output shaft of the loading motor 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com