Continuous heat accumulating type VOC (Volatile Organic Compounds) organic waste gas incinerator

An organic waste gas and incinerator technology, applied in the field of incinerators, can solve the problems such as the removal rate cannot be further improved, the reversing control system is complicated, the temperature change is uneven, etc., and achieves enhanced equipment adaptability, simplified operation and control system, internal The effect of small air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

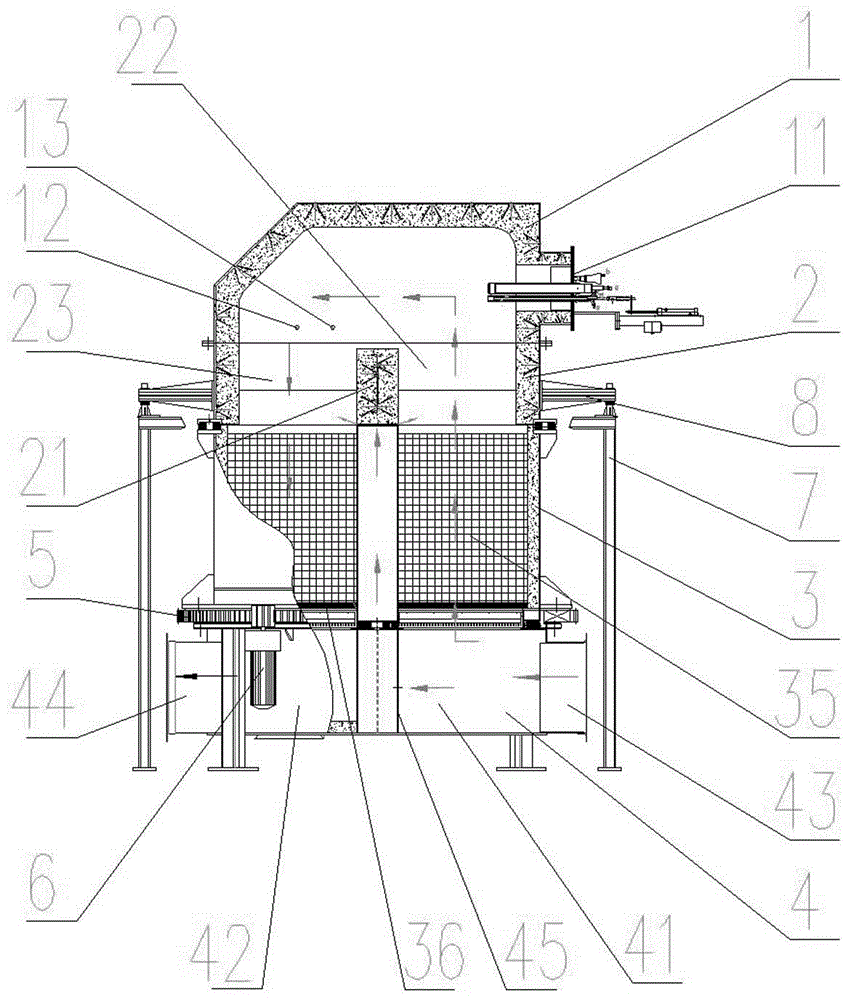

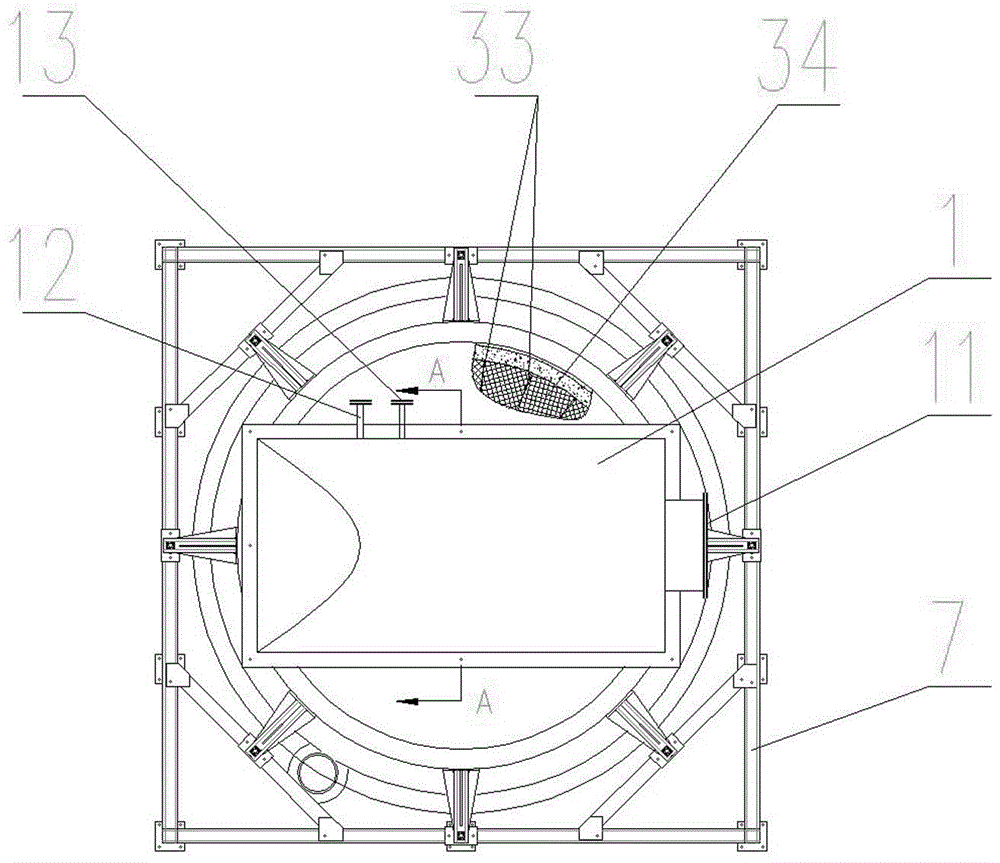

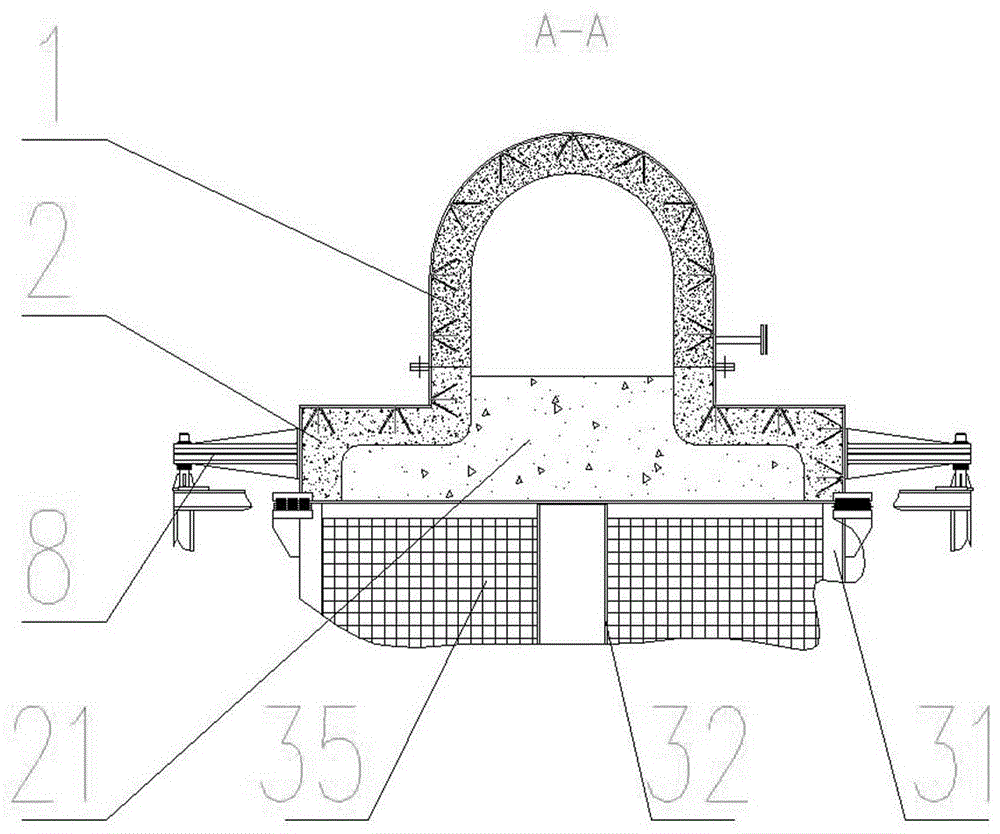

[0024] Such as Figure 1~3 As shown, a continuous regenerative VOC organic waste gas incinerator includes an incineration chamber 1, a fixed cover 2, a regenerator rotor 3 and a fixed seat 4 arranged sequentially from top to bottom, wherein: the incineration chamber 1 is Hollow structure, the bottom is completely open, the side wall is provided with a burner 11, the fixed cover 2 is a hollow cylindrical structure, the upper opening is connected with the bottom opening of the incineration chamber 1, the bottom is a fully open structure, and the middle is provided with The vertical partition wall 21 divides the space inside the fixed cover 2 into two parts, which are the waste gas rectification passage 22 and the high-temperature flue gas passage 23 respectively. The regenerator rotor 3 includes a cylindrical rotor housing 31 and a The central shaft 32 in the center of the rotor housing 31, the central shaft 32 and the rotor housing 31 are connected by twenty-four grid plates 33...

Embodiment 2

[0029] Similar to Embodiment 1, the central axis 32 described in this embodiment is a hollow cylinder, and the upper bottom surface and the lower bottom surface are respectively provided with an upper sealing plate with holes and a lower sealing plate with holes, and the fixing seat partition is provided with There is a hollow column 45 aligned with the central axis 32, the upper bottom surface of the hollow column 45 and the side connected to the air intake chamber 41 are provided with a through hole, and a part of the gas in the air intake chamber 41 can be introduced into the central axis 32.

[0030] More preferably, the inner walls of the incineration chamber 1, the fixed cover 2, the regenerator rotor 3, and the fixed seat 4 are all provided with thermal insulation layers to ensure sufficient strength and life under high temperature conditions.

[0031]In this embodiment, the burner 11 includes a gas gun, a pilot lamp, a flame detector, an ignition gun and its propeller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com