Adaptive control method for intermediate shaft brake of commercial vehicle transmission without synchronizer

An adaptive control and brake technology, applied in transmission control, gear shifting mechanism, brake actuator, etc., can solve the problems of large workload of TCU data calibration, long development cycle of AMT transmission, poor product adaptability, etc. The effect of large inertia, guaranteed control effect and good shift quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

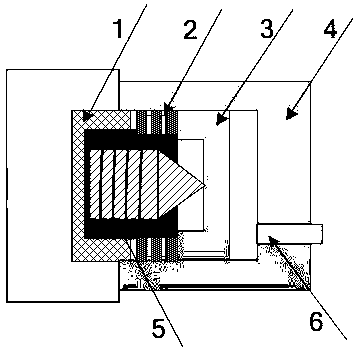

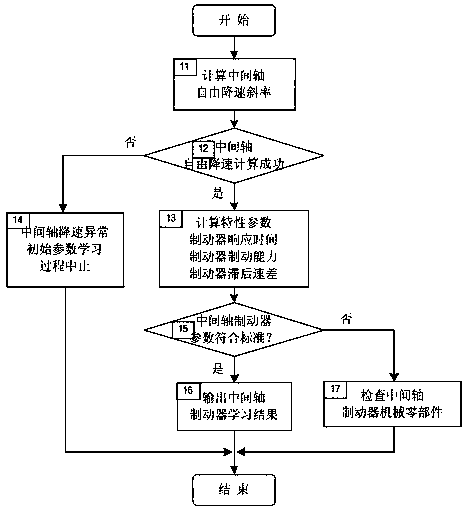

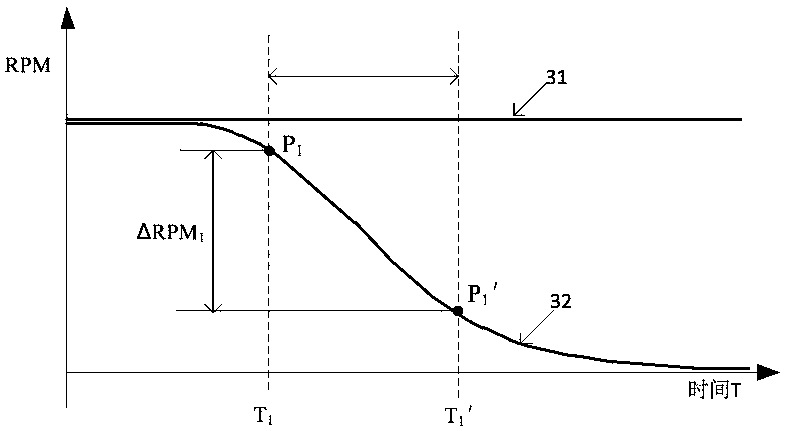

[0024] In order to clearly set forth the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings; figure 1 As shown, it is the mechanical structure of the intermediate shaft brake system of the AMT non-synchronized transmission patented by the present invention, which includes brake friction plates 2, brake cylinders 4, brake pistons 3, brake return springs 5, and brake air pipes 6; wherein the brake friction plates are A plurality of wet friction plates are connected with the spline 1 of the intermediate shaft of the transmission. When the intermediate shaft brake is used to control the speed of the intermediate shaft, the TCU controls to open the electromagnetic valve of the intermediate shaft brake, and the high-pressure gas enters the brake cylinder 4 from the air pipe 6, and the brake piston 3 presses the brake friction plate 2 under the action of the high-pressure gas, and the brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com