An automatic fault detection method for a gas water heater

A gas water heater, automatic detection technology, applied in the combustion method, fluid heater, adjustment of fuel supply and other directions, can solve the problem of increasing the minimum combustion power, high outlet water temperature, unable to completely solve the problems of flameout and whistling, etc., to avoid Low voltage and/or whistling alarm, improving intelligence and reducing the effect of fault alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

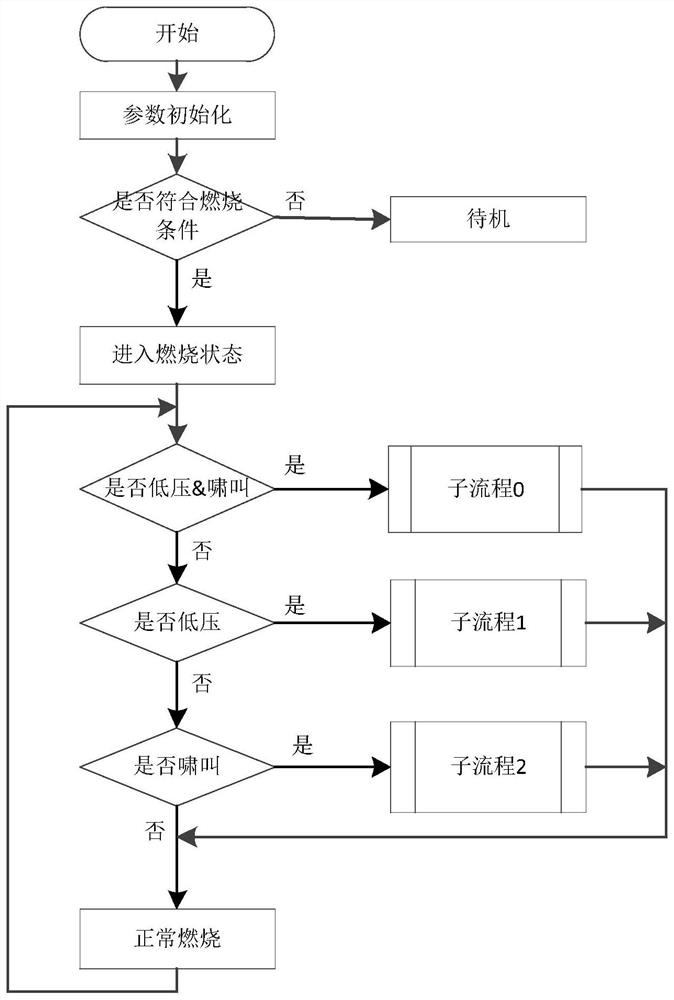

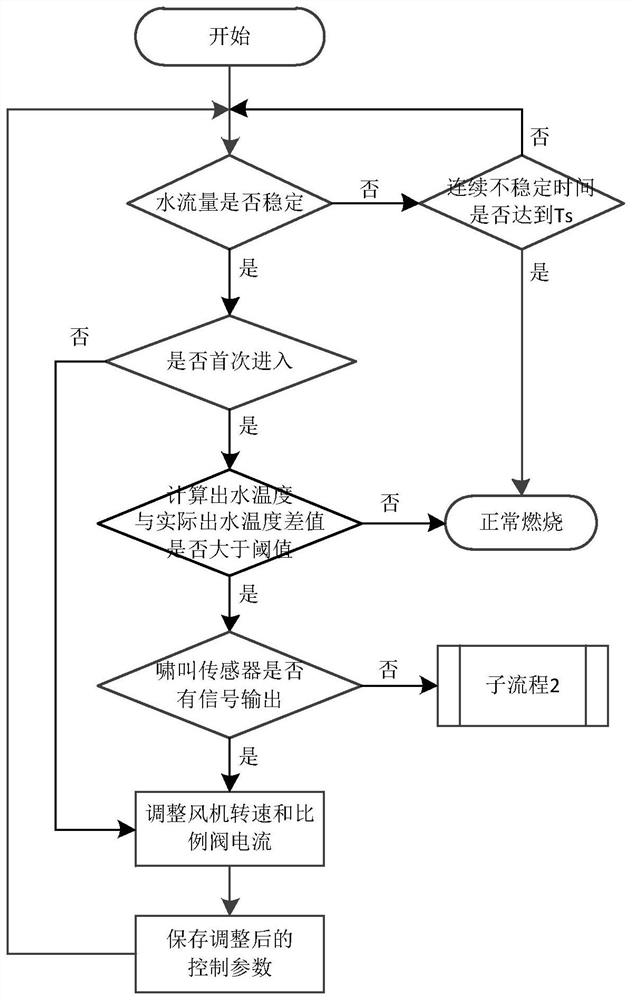

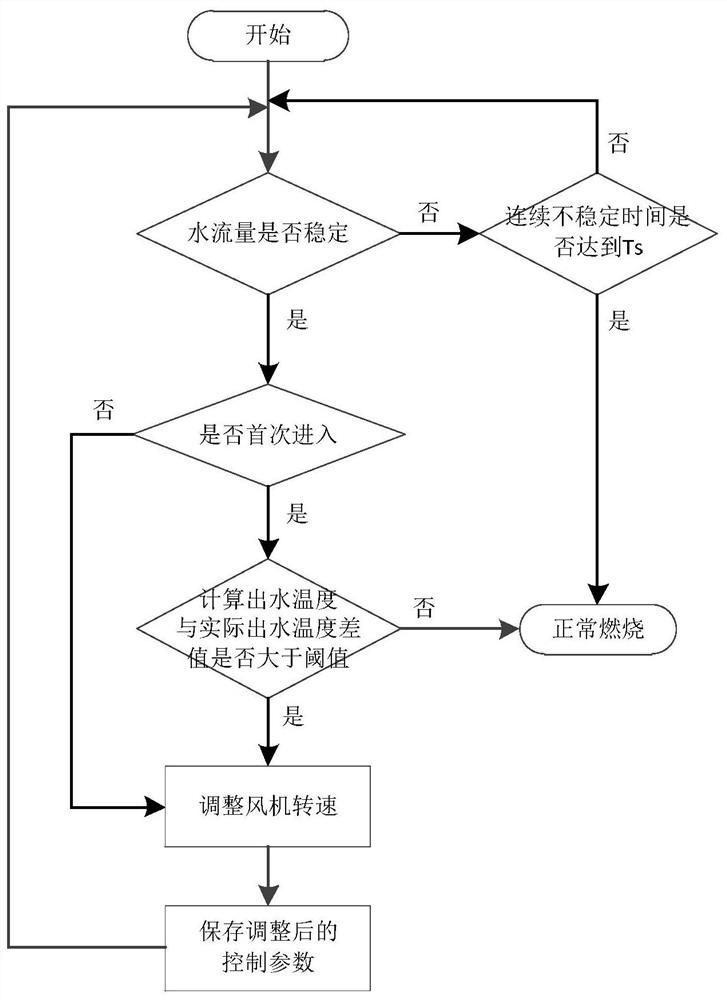

[0026] Such as Figure 1 ~ Figure 4 As shown, this embodiment discloses a test method for hot water performance of a gas water heater, especially a test method for low-pressure combustion flameout and combustion whistle faults of a gas water heater. The test method includes the following steps:

[0027] (1), first, initialize the combustion control parameters of the gas water heater, and restore the combustion control parameters to the default parameter values of normal combustion; wherein, the initialized control parameters include the theoretically calculated fan speed R 理论 and the actual fan speed R 实际 The difference △R, theoretically calculated proportional valve output current I 理论 and the actual proportional valve output current I 实际 The difference △I, and the following conditions are met: △R=0, △I=0, that is, the gas water heater b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com