Expandable and high-reliability hydraulic lock

A hydraulic lock, reliable technology, applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of hydraulic system or hydraulic lock damage, unreliable main valve core sealing, complex external interface, etc., to prevent Stuck, improved machinability, and the effect of strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and examples. details as follows:

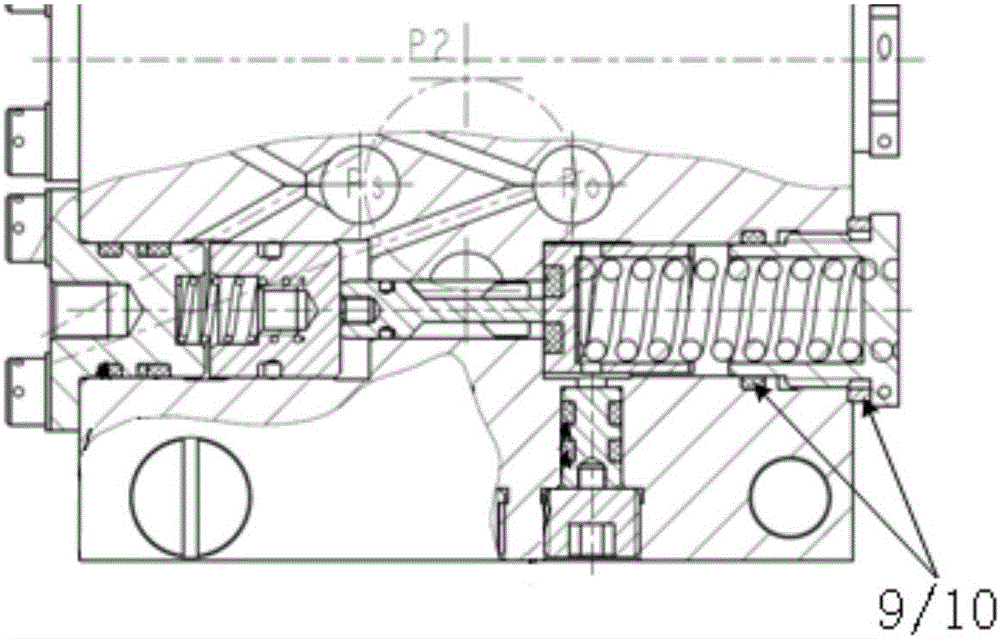

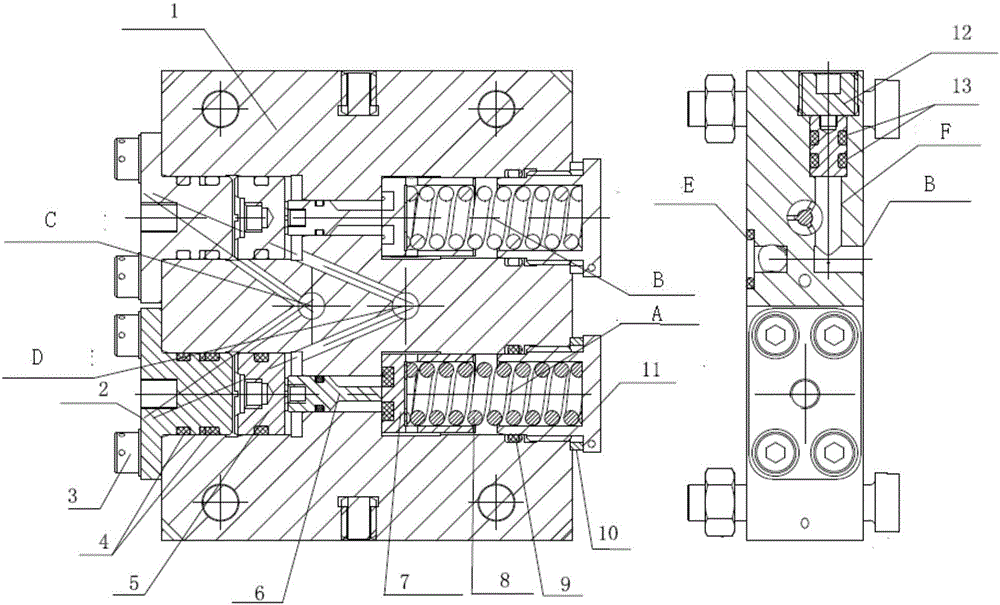

[0031] Hydraulic lock structure diagram see figure 1 . The connection relationship is: the main oil circuit interface E and the control oil circuit interface G are set on the housing 1; the housing 1 has two locking chambers, namely the locking chamber A and the locking chamber B, and the corresponding number of control spools installation cavity;

[0032] The control spool is composed of two spools with different diameters, and the diameter of the installation cavity is designed according to the diameter of the corresponding spool; The installation cavity of the control spool 6 communicates with the locking cavity; the control oil circuit interface communicates with the lock opening control cavity C and the lock closing control cavity D respectively through the flow channel; the lock opening control cavity communicates with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com