Pump

A fluid pumping and housing technology, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as poor heat dissipation and high pump noise, and achieve high motor efficiency, small flow pulsation, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0026] The pump in the present invention, especially a submersible pump, adopts a double-walled oil outlet shell structure to reduce noise.

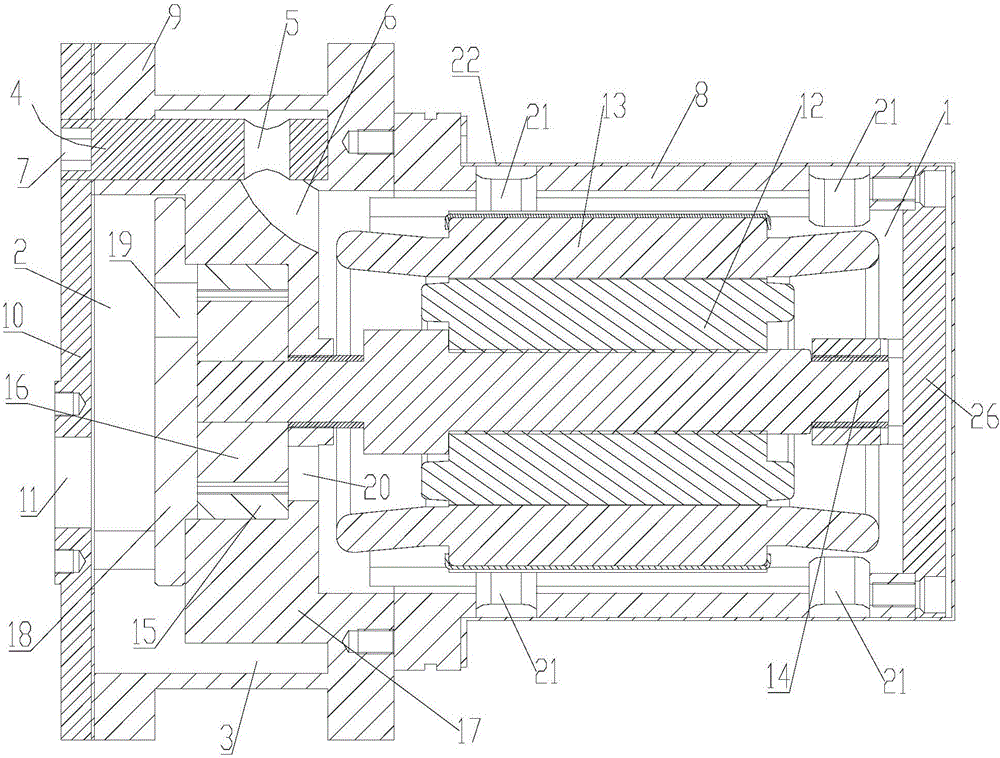

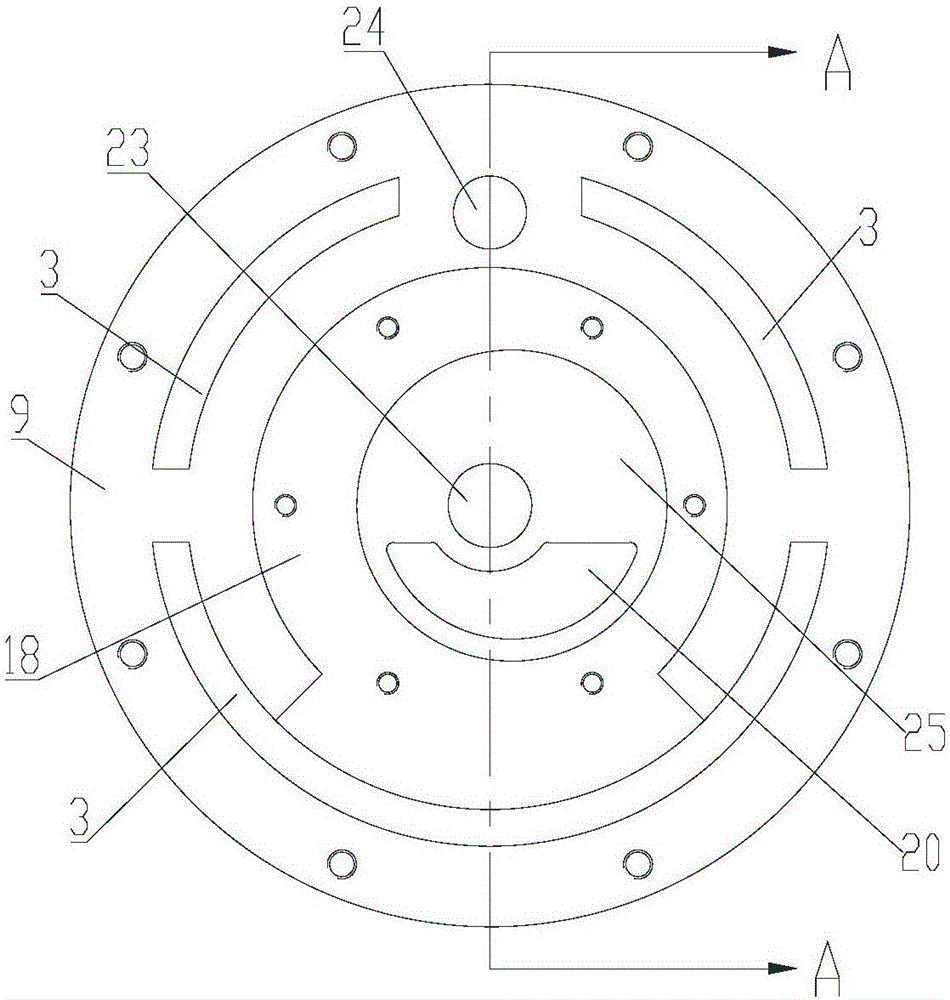

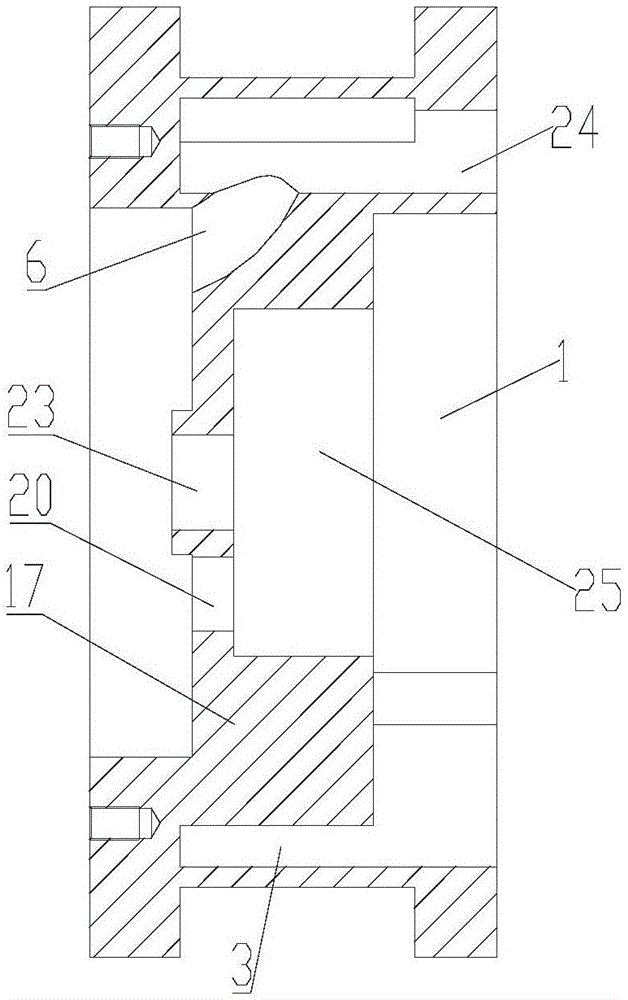

[0027] Such as figure 1 As shown, the pump in the present invention includes a housing, a driving part and a fluid pumping part. Wherein, a supporting partition is provided inside the housing, thereby dividing the inside of the housing into a first cavity 1 and a second cavity 2, the driving part is installed in the first cavity 1, and the fluid pumping part is installed in In the mounting cavity of the support partition.

[0028] A through hole 23 is provided on the support partition, so that one end of the driving part can be connected with the fluid pumping part after passing through the through hole 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com