Combined aluminum alloy door window corner structure

An aluminum alloy door and window, combined technology, applied in the direction of windows/doors, building components, building structures, etc., can solve the impossibility of composite processing through strips, the inability to assemble aluminum alloy double-layer windows, and the increase in the cost of extrusion dies and other problems, to achieve the effect of convenient and flexible assembly, reduced profile section area, and profile section size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

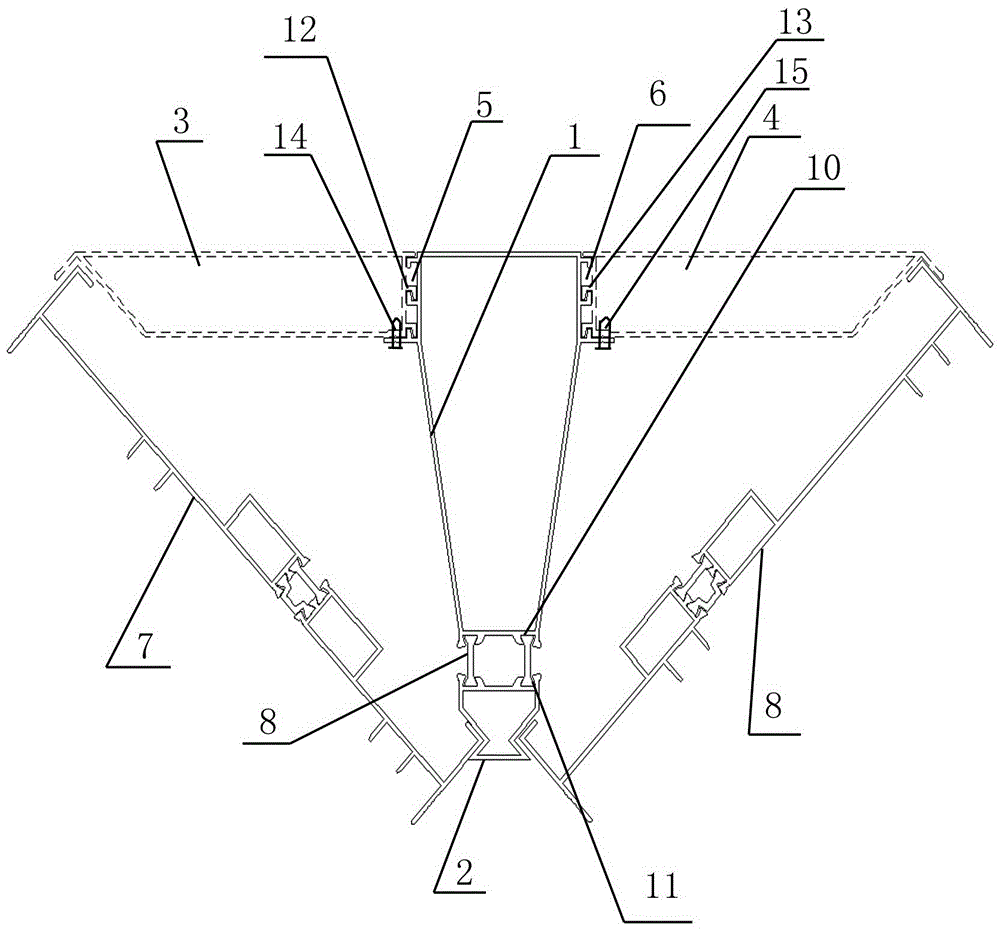

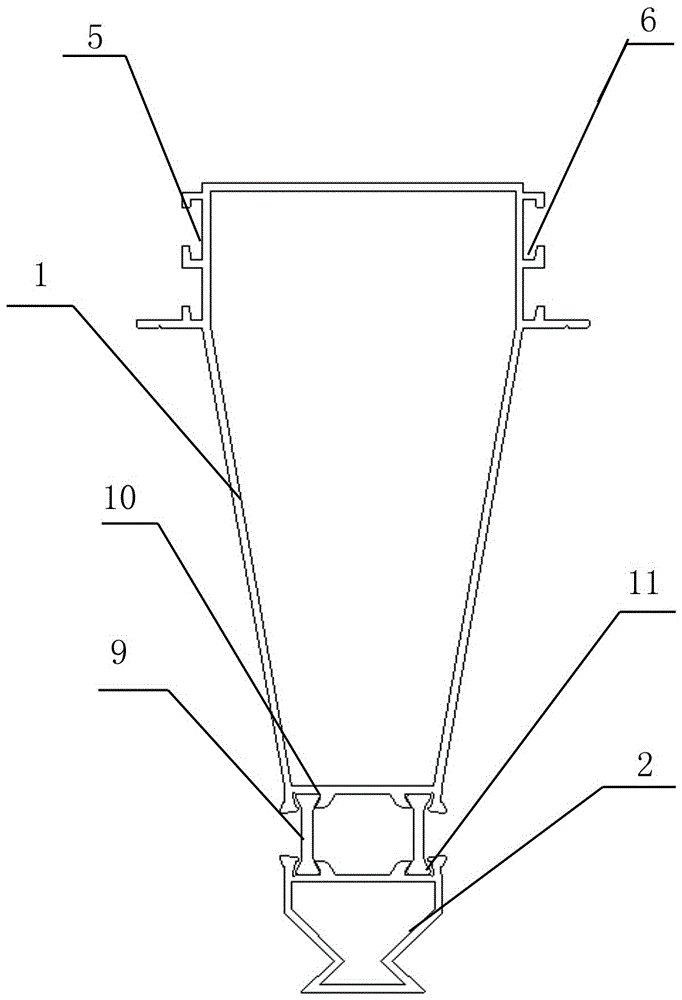

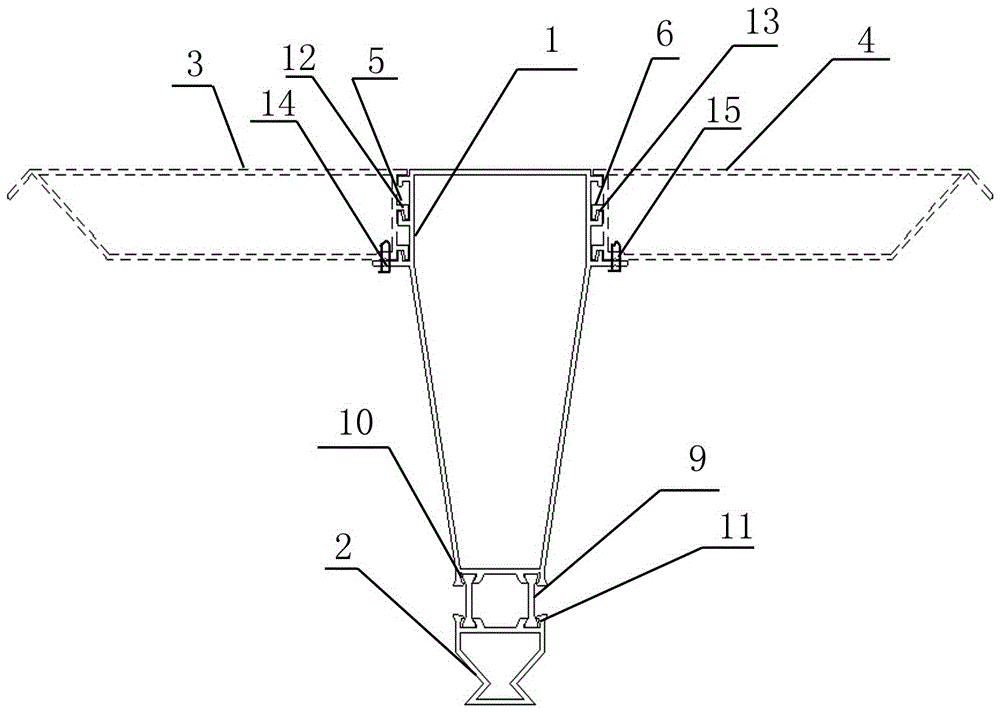

[0010] exist figure 1 , figure 2 with image 3 Among them, the present invention provides a combined aluminum alloy door and window corner structure, which includes an upper corner main material 1 and a lower corner main material 2, and left corner auxiliary materials 3 and right Corner auxiliary material 4, one end of left corner auxiliary material 3 is inserted into the left slot 5 provided on the left side of the upper corner main material 1 and is detachably connected with upper corner main material 1, and one end of right corner auxiliary material 4 is inserted into the upper corner The right slot 6 provided on the right side of the upper corner main material 1 is detachably connected with the upper corner main material 1, and a heat insulation strip combination is arranged between the bottom of the upper corner main material 1 and the lower corner main material 2, and the left A left double window vertical material 7 is provided between the other end of the corner aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com