Equipment and method for reinforcing dike

A technology of dams and equipment, which is applied in the fields of flood control and emergency rescue and dam maintenance, which can solve the problems of inability to use flooded and weak dams for emergency construction, difficulty in effective compaction, and low efficiency, so as to achieve the effect of quickly and effectively evacuating dangers or reinforcing dams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

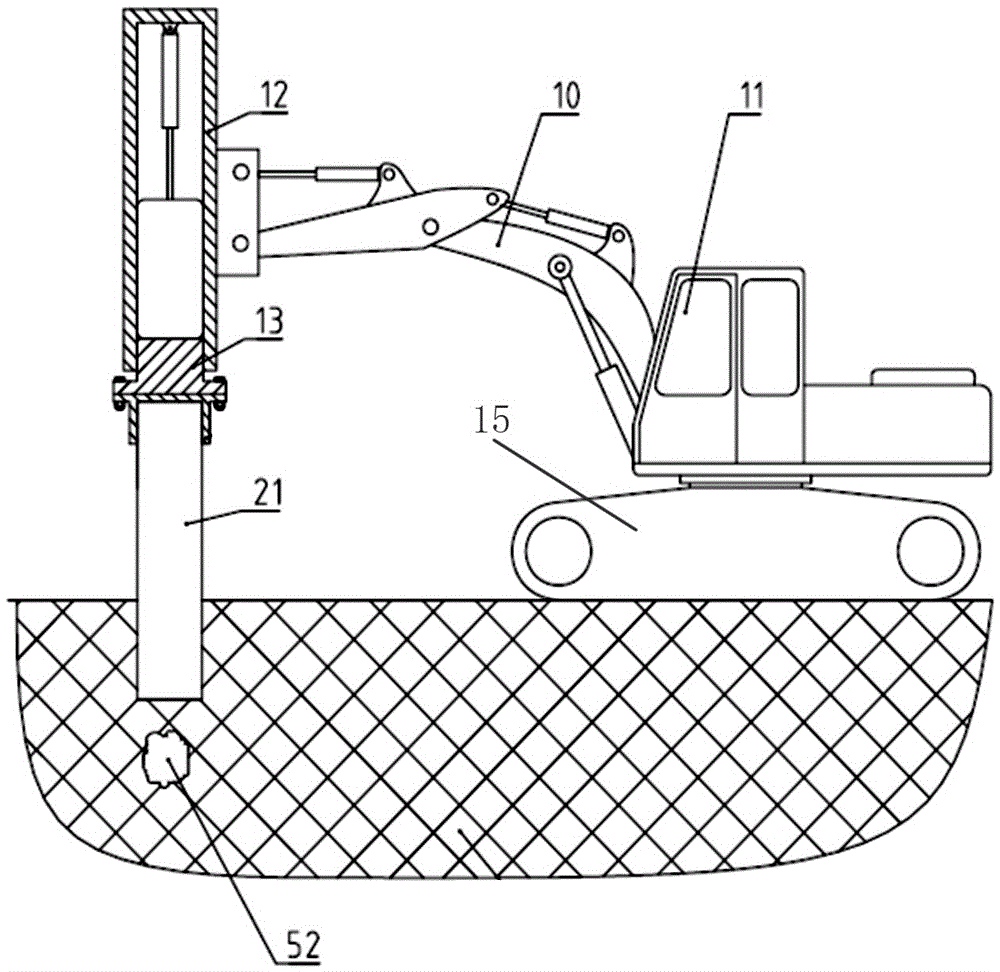

[0018] Embodiment 1: When water seepage occurs in the embankment, the following steps are adopted: 1. First, the embankment leakage detector is used to detect and determine the water seepage position and depth of the embankment to be reinforced. 2. Drive the equipment to the position where the embankment needs to be reinforced. Generally, the permeable position is located at the lower part of the dam and runs through the water flow channel of the dam, and the equipment is driven to the position determined by the detector. 3. Select the pile 21 and the attachment 13. In this embodiment, a cylindrical pile 21 is used, and the attachment 13 of the sleeve structure is installed on the lower part of the high-speed hydraulic compactor 12 , and the transmission arm 10 is operated to press the attachment 13 on the upper end of the pile 21 . 4. Carry out piling 21, start the operating device, and the high-speed hydraulic compactor 12 will start piling 21 under the action of the hydrau...

Embodiment 2

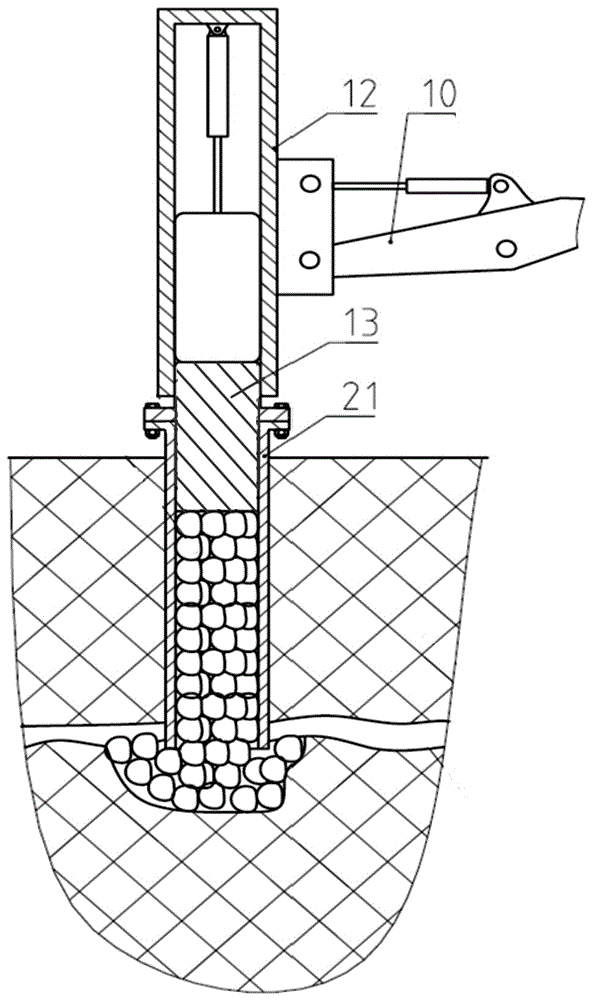

[0019] Example 2: When there is a piping danger in the embankment, the piping is the phenomenon that the soil particles in the dam body or the dam foundation are taken away by seepage, and most of them are caused by the weakness of the permeable area and the surrounding soil after water penetration, so it is necessary to fill the affected area with filler. The best method, this embodiment adopts the following steps: 1. Determine the position and depth to be reinforced. Since the piping phenomenon is relatively obvious, the position and depth to be reinforced can usually be determined based on observation and judgment. 2. Drive the equipment to the position where the embankment needs to be reinforced. Step 3. Select the pile 21 and the attachment 13. This embodiment uses a high-speed hydraulic tamping machine 12 with a striking energy of 16kJ. The pile 21 selects a circular steel pipe and the mandrel attachment 13 matched with the pile 21. The diameter of the steel pipe can be...

Embodiment 3

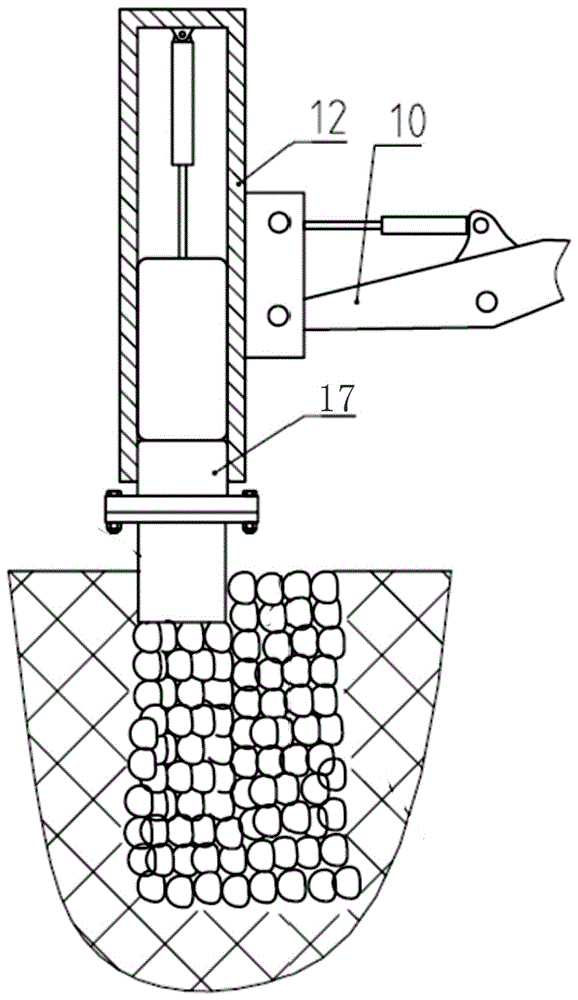

[0020] Embodiment 3: When the top of the embankment needs to be reinforced or routinely maintained, the method for embankment reinforcement is as follows: 1. Determine the position where the embankment needs to be reinforced, and drive the equipment to the above position. 2. Choose filler. According to the degree of weakness of the embankment, choose suitable fillers, such as crushed stones, block stones or sandstones. In this embodiment, block stones and sandstones are used in combination. The strength of block stones is high. Mixing sandstones can fill the gaps between block stones. , to prevent leakage. 3. Place the packing at the position that needs to be reinforced, and operate the transmission arm 10 so that the lower hammer body or the ramming plate 17 of the high-speed hydraulic compactor 12 is aligned with the packing. In this embodiment, the ramming plate 17 is installed at the lower part of the lower hammer body. Hit the stuffing. 4. Start the hydraulic system to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com