Bolt reclaiming template mechanism

A technology of formwork and bolts, which is applied in the field of bolt retrieving formwork mechanism, can solve the problems of increased labor costs and missing bolts, and achieve the effects of reduced labor costs, high reliability and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

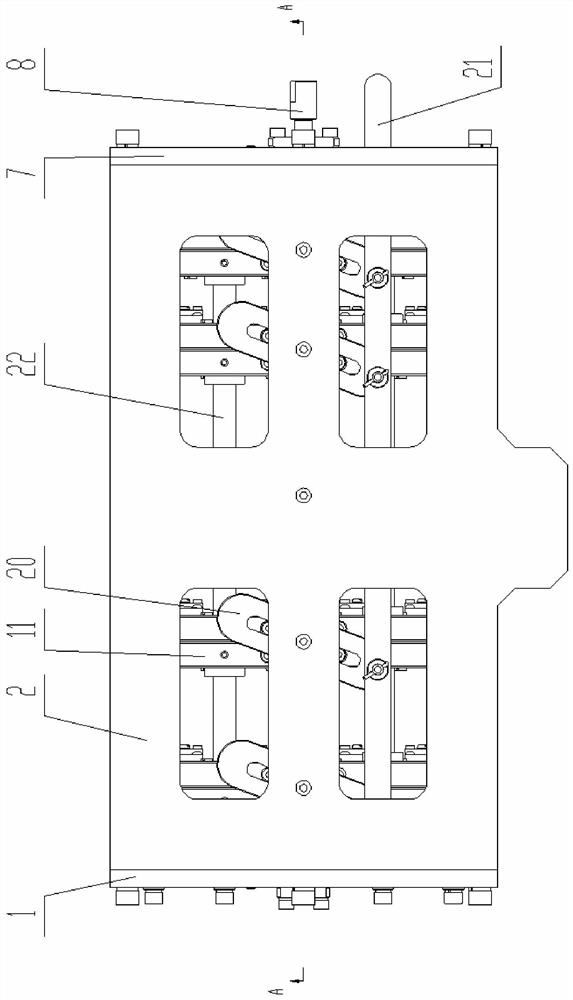

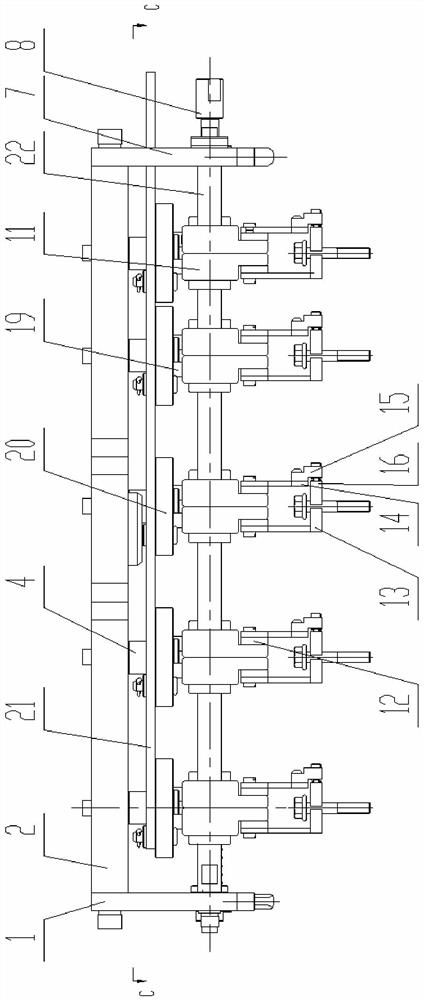

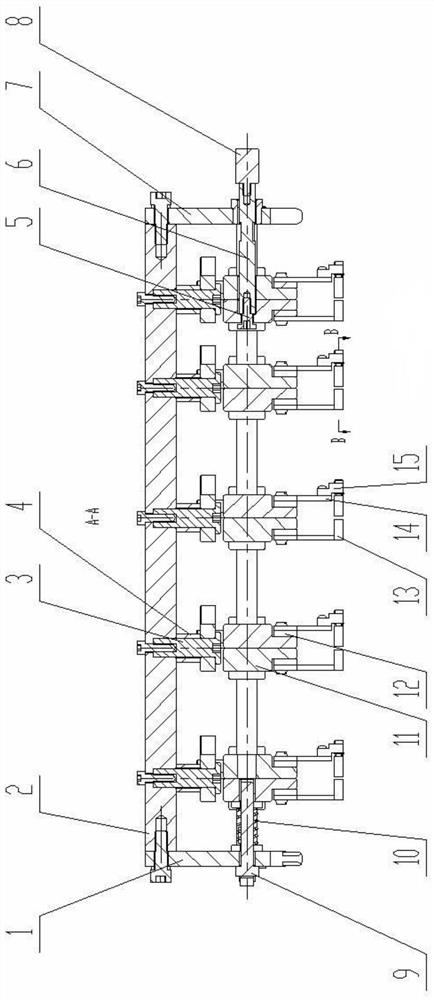

[0032] A specific embodiment of the present invention is shown in the attached drawings, the bolt reclaiming template mechanism includes a support mechanism, 5 sets of clamping mechanisms, a shaft 22, an impact mechanism and a link mechanism; the 5 sets of clamping mechanisms are uniformly sleeved on the shaft 22 The two ends of the shaft 22 are connected with the support mechanism; the impact mechanism is installed at both ends of the support mechanism, and is connected with the clamping mechanisms on both sides respectively; the link mechanism is installed on the support mechanism, and is sequentially connected with the five clamps The holding structure is connected to drive the clamping mechanism to carry out the clamping and reclaiming work.

[0033] The support mechanism includes: a left support plate 1, a support plate 2, and a right support plate 7; the left support plate 1 and the right support plate 7 are respectively fixed on both ends of the support plate 2, and toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com