Adjustable film coating quality type metallized film vacuum coating machine

A technology of metallized film and vacuum coating machine, applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve problems such as uneven preheating, non-adjustable, and inability to meet three-dimensional three-dimensional adjustments , to achieve the effect of adjustable coating thickness, adjustable preheating and uniform preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further describe the present invention, it is further described below in conjunction with embodiment.

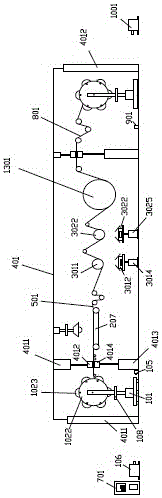

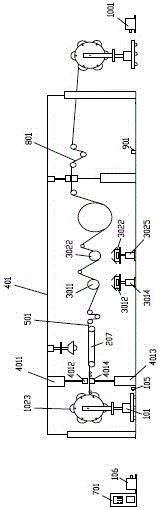

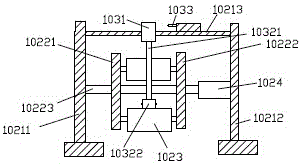

[0033] Such as figure 1 As shown, the present invention includes a vacuum chamber 401 and a feeding mechanism, a coating mechanism, and a winding mechanism arranged in the vacuum chamber 401 . The feeding mechanism, the coating mechanism, and the winding mechanism are arranged in sequence from front to back according to the process flow.

[0034] Such as figure 1 As shown, the feeding mechanism includes a first lifting mechanism 101 and a feeding device. The telescopic end of the first lifting mechanism 101 cooperates with the feeding device to drive the feeding device to move up and down.

[0035] Such as figure 1 As shown, the vacuum chamber 401 includes a chamber entrance door 4011 at the entrance end and a chamber exit door 4012 at the exit end.

[0036] Such as figure 1 As shown, the feeding device includes a first support frame, a first rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com