Lubricating agent composition for white alloy cold drawing machining

A technology of cold drawing and white metal, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor corrosion resistance, low strength and hardness, and achieve the effects of controlling temperature, improving quality and tolerance, and reducing friction

Inactive Publication Date: 2017-02-22

GUANGXI UNIV

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

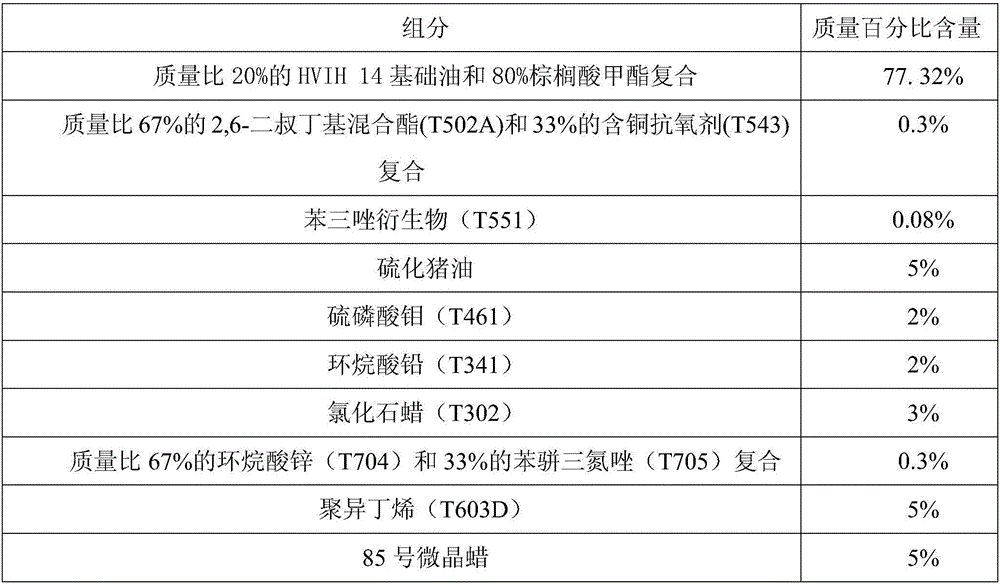

[0027] The following components are blended according to mass percentage:

[0028]

[0029] Typical technical index of embodiment 2 product:

[0030] project index Kinematic viscosity at 40℃mm 2 / s

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a lubricating agent composition for white alloy cold drawing machining. A compound of HVIH14 and methyl palmitate is adopted as basic oil and cooperates with various composite additives. The lubricating agent composition includes antioxidant, a metal passivator, an oiliness agent, antiwear agent, an extreme pressure agent, a friction improver, a viscosity index improver, a filling agent, antirust agent and others. The composition has the advantages that the number of machined workpieces and molds needing to be rubbed, lubricated and cooled is reduced, power consumption is lowered, and deformation is uniform; the service life of a tool is prolonged, and abrasion of workpiece materials is controlled; the quality of the surface of machined metal is improved, and the tolerance of the surface of the machined metal is reduced; temperature is controlled, and machining deformation is reduced; new and old surfaces of the machined metal are kept oxidized or passivated; using is safe, and toxins do not exist; residues do not affect machining and operating, and cleaning is convenient.

Description

technical field [0001] The invention belongs to the field of metal processing lubricants, in particular to a composition of a white metal cold drawing processing lubricant. Background technique [0002] White metal was named after the invention of American Babbitt, because of its white color, it is also called Babbitt alloy. Including tin-based bearing alloys and lead-based bearing alloys, are widely used. It has anti-friction properties and is the only material suitable for rotating relative to a low-hardness shaft. Compared with other bearing materials, it has better adaptability and press-fit properties. It is widely used in large marine diesel engines, turbines, alternators, and Other mining machinery and large rotating machinery, etc. Its main alloy components are tin, lead, antimony and copper. Antimony, copper, used to increase the strength and hardness of the alloy. [0003] The microstructure of Babbitt alloy is that hard phase particles are evenly distributed o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/06C10N40/24C10N10/04C10N10/08

CPCC10M169/044C10M2203/1006C10M2205/026C10M2205/14C10M2207/16C10M2207/28C10M2207/2815C10M2211/066C10M2215/223C10M2219/024C10M2219/044C10M2223/045C10N2030/06C10N2040/24C10N2010/08C10N2010/04

Inventor 黄福川李康春邓富康

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com